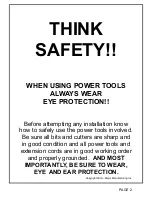

With both clamps opened

equally, install both inside and

outside templates to the HIT-66

clamp as shown. Do not tighten

the 10-32 screws at this time.

When all screws have been

loosely installed, then it is ok to

tighten.

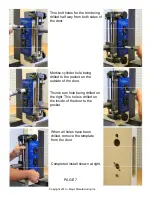

There are two clamps on the

rod guides, one top and one

bottom. When aligned to the top

and bottom scribe lines on the

guide plate, they will limit the

travel. They are set up for a

standard 6-1/2” mortise. The

bottom of the top clamp should

be on the top line, and the top of

the bottom clamp should be on

the bottom line. Tighten the

screws when adjusted. To

change the size of the mortise,

use the scribe lines as a guide

and adjust accordingly. To

change the size of the mortise

by 1/8” move each clamp 1/16”

in the desired direction.

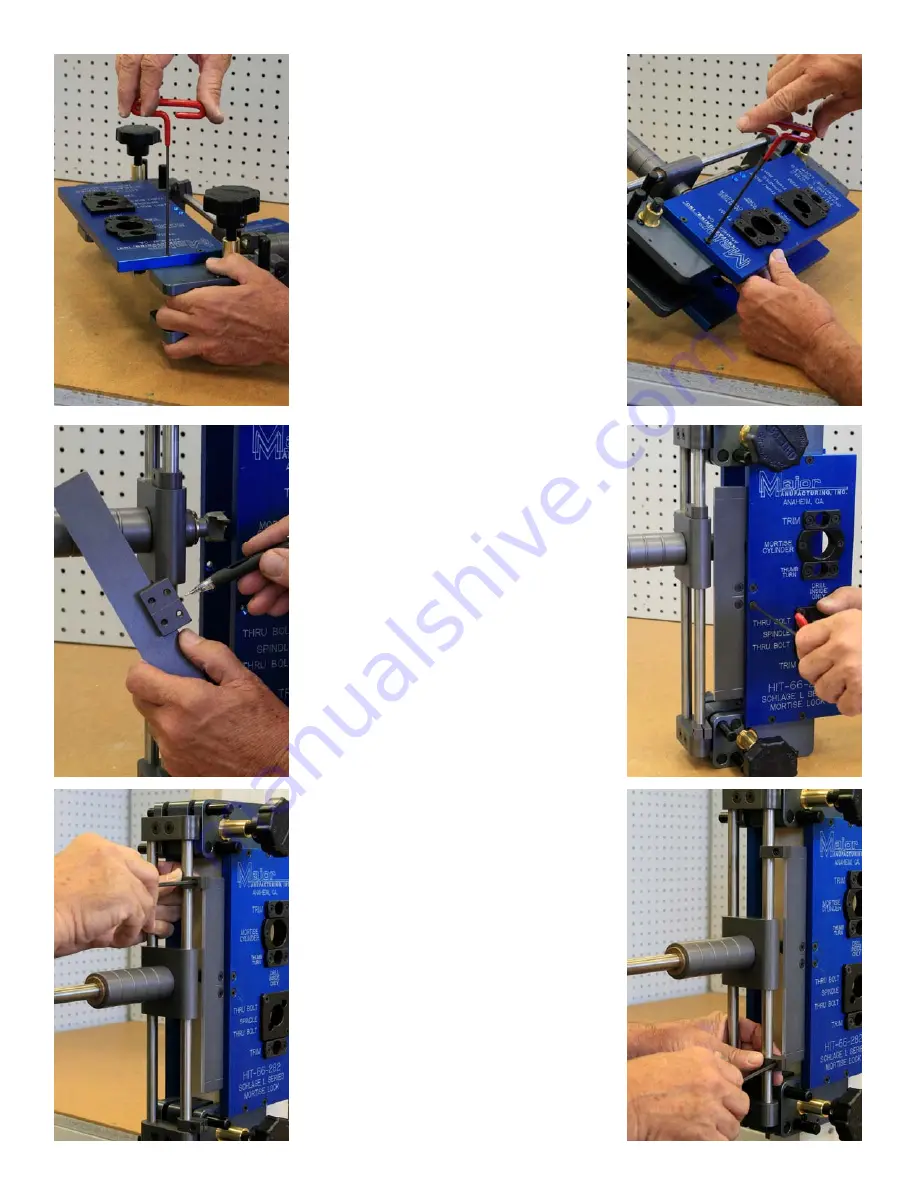

The next part to attach to the

template is the alignment guide.

When installed, it will align the

mortise pocket to the drill guide.

Notice the scribe mark in the

picture at the left. The guide can

be attached to either template, it

is attached with two 10-32 x 3/4”

flat head socket screws.

PAGE 4