Pay Attention to the Thread Direction!

Notice that your motors have a shaft that holds the

prop in place. This shaft is threaded, and a nut of

some type (called the

prop nut

) fits over that thread

and puts pressure on the prop. In the early days of

small drones, those threads were all standard clock-

wise threads. Because our motors spin in both

clockwise and counterclockwise directions, manu-

facturers realized that if they created motors with

standard and reverse threads, they could use the

spinning prop direction to help keep it tight. Make

sure that you always have a thread that screws on in

the opposite direction from that in which the prop

will be spinning.

Clockwise spinning motors should have a reverse-

threaded shaft. Counterclockwise motors work best

with a standard thread.

One catch: not all manufacturers make their motors

this way. Many still only use a standard thread on all

of their motors. This will still work fine; just be sure

to tighten it well and check it regularly (as you

should anyway).

The moral to the story is to always know what type

of threads your motor shaft has and be sure you are

installing them in the right location. If you need to

confirm the direction that your motor will be spin-

ning, do so before attaching it to the frame.

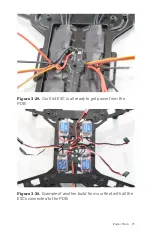

For our Little Dipper build, our motors will spin

clockwise on the NE and SW motors while the NW

and SE motors spin counterclockwise.

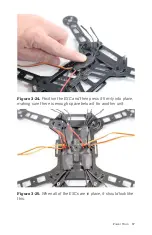

Start your mounting process by laying the motor flat on the top

of the boom while lining up the mounting holes in the bottom of

the boom with the threaded holes in the bottom of your motor

(see

). Make sure that you have a motor with the cor-

rect thread direction for the anticipated motor direction. The

Power Train 73

Summary of Contents for Belinda Kilby

Page 1: ......

Page 3: ...Make Getting Started with Drones Terry Kilby and Belinda Kilby...

Page 26: ......

Page 90: ......

Page 126: ......

Page 153: ...Figure 9 10 Compass setup Figure 9 11 Compass calibration ArduPilot Mega APM Setup 141...

Page 198: ......