20

b) Mounting of bearings

Required tool:

10 mm hexagon socket (from a socket wrench set) or comparable tool as a tool for mounting the bearings

Push the bearings into the aluminium parts as shown in the following illustrations. Here a hexagon socket wrench or a comparable tool can be helpful. Do not

use rough force, this can damage the base plate and the ball bearings! Avoid tilting, with some sensing the position can be pressed in without great resistance.

Make sure that the edge of the bearing is flush with the aluminium part.

If a bearing cannot be pressed in, it may be caused by a protruding burr or too much paint. You can easily rework the bore with a knife (e.g., cutter

knife for wallpaper or floors) or with a file. If the bore has become too large, the bearing can be glued to the flange of the bearing with a small drop of

glue (e.g., Uhu

®

Endfest or comparable).

The bearings may come loose during final assembly due to uneven pressing of the cylindrical pins into the plastic holders. This is, however, not too

bad, as the pins can easily be pushed back into the intended hole.

Sticking should be a last resort. The bearings clamp sufficiently strongly in the holes for the operation of the robot even without glue.

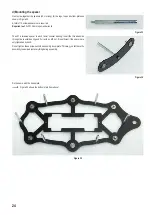

Figure 24

Figure 24 shows the bottom plate from above!

Figure 25 shows how you can press the bearings into the base plate using the femur

aluminium parts as a support.

The hexagon wrench must press against the edge of the bearing. Masking the alu-

minium parts with painter tape protects them from scratching. Other parts that can be

found in the hobby workshop can also be used as underlay.

Do not use adhesive tape that cannot be removed without leaving a residue.

Figure 25

Summary of Contents for 1664151

Page 1: ...Operating Instructions Hexapod Robobug Complete Set Item no 1664151...

Page 23: ...23 The femur servo mount must be mounted a total of 6 times Figure 31 Figure 32...

Page 26: ...26 Figure 37...

Page 36: ...36 Figure 58 Figure 59...

Page 37: ...37 Figure 60 Illustration_61 Figure 61...

Page 38: ...38 Figure 62...

Page 66: ...66...

Page 67: ...67...