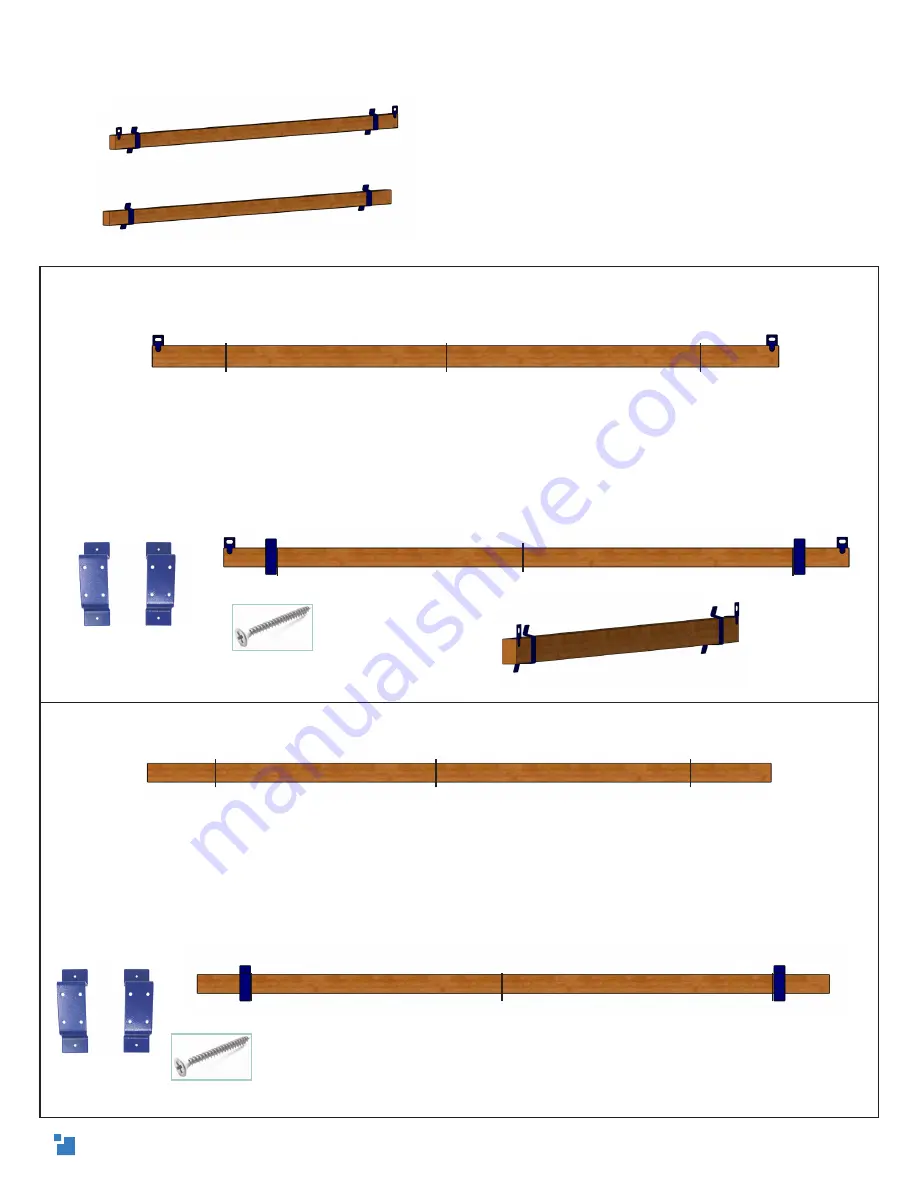

4.

(A)

On the front face of the top beam, measure and mark 51.5in (130.8cm) from the center on

each side. Draw a straight line with the speed square.

(B)

Position a

stud mount

on the outside of each 51.5in line, with the shorter angle of the stud

mounts toward the top. On one side, push the bottom of the mount against the bottom of the top

beam, use a speed square as a guide to keep it on the 51.5in line, and screw it into the top beam

with four

short wood screws

. The bottom of the mount should be as flush as possible with the

bottom of the top beam and exactly perpendicular to the beam. Repeat on the other side. Use

the above Drew’s Note for mounting tips!

5.

(A)

On the front 4in face of the bottom beam, measure and mark 51.5in (130.8cm) from the

center on each side. Draw a straight line with the speed square.

(B)

Exactly like attaching to the top beam, position a

stud mount

on the outside of each 51.5in

line, with the shorter angle of the stud mounts toward the top. On one side, push the bottom of

the mount against the bottom of the top beam, use a speed square as a guide to keep it on the

51.5in line, and screw it into the top beam with four

short wood screws

. The bottom of the mount

should be as flush as possible with the bottom of the top beam and exactly perpendicular to the

beam. Repeat on the other side.

Attaching the stud mounts

Drew’s Note: For the M2’s alignment calibration

calculation (that’s fun to say), we have to

make sure that the stud mounts are exactly

perpendicular to the beams. To ensure this,

attach each screw part-way before moving

to the next. Repeat on the other two holes and

screw in each from opposite sides by small

increments until they are all tight - just like

changing a tire.

1.5in short wood screw

center

51.5in

51.5in

center

51.5in

51.5in

center

51.5in

51.5in

center

51.5in

51.5in

1.5in short wood screw

stud mount

Side view

stud mount

7