DPC-2200 USER MANUAL

Page 26 of 38

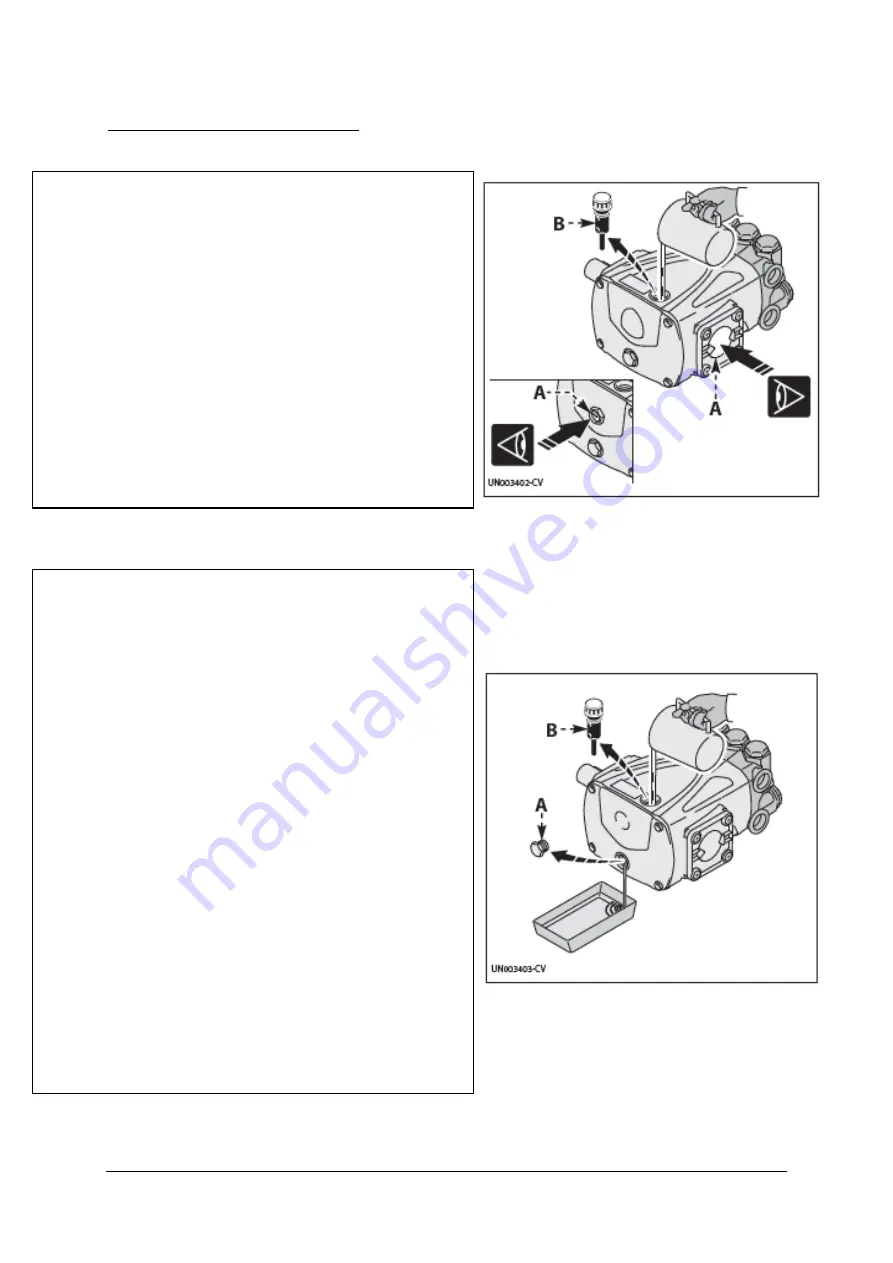

CHECKING PUMP OIL LEVEL

Check the oil with the pump level and cold.

Check the amount of oil through the level

gauge (A).

If necessary, top up with oil with the

characteristics specified in the

‘lubricants

table’.

To top up with oil proceed as described below.

1. Unscrew the plug (B) and pour oil in until it is

halfway up the level gauge (A).

2. Screw on the plug (B).

Position the machine so the pump is perfectly

level, with the pump slightly warm. Do not

release oil into the environment.

Dispose of spent oil in accordance with

statutory requirements.

To change the oil, proceed as described below.

1. Position a receptacle of suitable capacity to

collect the spent oil.

2. Unscrew the drain plug (A) and allow all the

oil to flow out.

3. Screw on the drain plug (A).

4. Unscrew the filler plug (B).

5. Pour in the fresh oil through the filter hole

until the correct level is reached.

6. Screw on the filler plug (B)