6 - 70

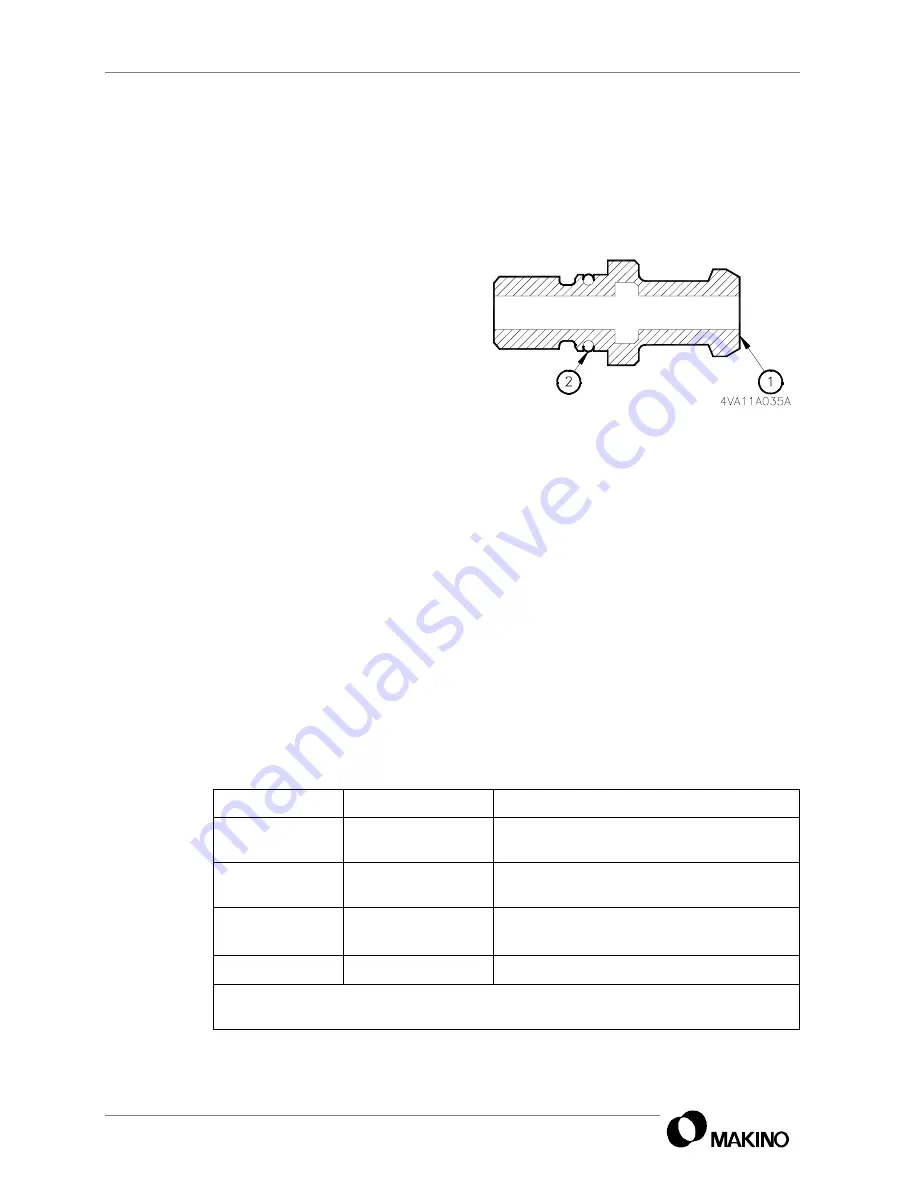

TSC - Tool Holder Retention Knob

TSC requires special; tool holders, retention knobs, and cutting tools

designed to allow coolant to pass through the center.

shows

retention knob details.

A rubber seal in the end of the

sealing rod seals between the

retention knob and TSC mecha-

nism. To prevent damage to the

seal and provide a good seal, the

end of the retention knob [1] must

be a ground surface.

An O-ring on the retention knob

shank [2], ensures a good seal

between the tool holder and the retention knob.

Sealing Rod Seal Replacement

Inspect the seal on the sealing rod daily and replace immediately when

any signs of wear or damage are indicated. In addition to a visual inspec-

tion, other signs of a damaged seal are:

•

Excessive coolant flow from the spindle taper during a tool change; as

the result of a coolant build-up in the area of the collet fingers.

•

Coolant contaminated spindle lubricant.

lists the tools and replacement parts needed before starting the

sealing rod seal removal and installation procedure.

T

ABLE

6-20

SEALING

ROD

–

TOOLS

AND

PARTS

Name

Makino Part No.

Description and Use

Spindle Catch Jig 4V200A003A

Attaches to spindle bearing retainer to pre-

vent spindle rotation.

T- Wrench

13M71B409=1

Threads into end of inner sleeve for sealing

rod assembly removal and installation.

O-ring

P9 (2 Required)

Replacement for O-rings [5] and [6] (

Rubber Seal

13M11G704

Replacement for Seal [4] (

).

1.

The spindle catch jig and T-wrench are supplied with the machine. The

replacement O-rings and seals must be purchased from Makino.

F

IGURE

6-43

TSC

RETENTION

KNOB

Summary of Contents for V55

Page 6: ...vi...

Page 32: ...1 24 NOTES SKETCHES...

Page 37: ...4V2A1563 E 2 3 FIGURE 2 1 SPINDLE POWER AND TORQUE CHARACTERISTICS...

Page 39: ...4V2A1563 E 2 5 FIGURE 2 2 AXIS CONFIGURATION TRAVEL AND WORK CUBE...

Page 41: ...4V2A1563 E 2 7 FIGURE 2 4 WORKPIECE SIZE LIMITATIONS...

Page 53: ...4V2A1563 E 2 19 FIGURE 2 6 FLOOR SPACE FOR STANDARD MACHINE...

Page 58: ...2 24 F IGURE 2 7 V55 WITH 25 TOOL ATC...

Page 59: ...4V2A1563 E 2 25 F IGURE 2 8 V55 WITH 25 TOOL ATC AND LIFT UP CHIP CONVEYOR LEFT...

Page 60: ...2 26 F IGURE 2 9 V55 WITH 25 TOOL ATC AND LIFT UP CHIP CONVEYOR RIGHT...

Page 61: ...4V2A1563 E 2 27 F IGURE 2 10 V55 WITH 25 TOOL ATC LIFT UP CHIP CONVEYOR LEFT AND APC...

Page 62: ...2 28 F IGURE 2 11 V55 WITH 25 TOOL ATC LIFT UP CHIP CONVEYOR RIGHT AND APC...

Page 63: ...4V2A1563 E 2 29 F IGURE 2 12 V55 WITH 40 OR 80 TOOL ATC...

Page 64: ...2 30 F IGURE 2 13 V55 WITH 40 OR 80 TOOL ATC AND LIFT UP CHIP CONVEYOR LEFT...

Page 65: ...4V2A1563 E 2 31 F IGURE 2 14 V55 WITH 40 OR 80 TOOL ATC AND LIFT UP CHIP CONVEYOR RIGHT...

Page 66: ...2 32 F IGURE 2 15 V55 WITH 40 OR 80 TOOL ATC LIFT UP CHIP CONVEYOR LEFT AND APC...

Page 67: ...4V2A1563 E 2 33 F IGURE 2 16 V55 WITH 40 OR 80 TOOL ATC LIFT UP CHIP CONVEYOR RIGHT AND APC...

Page 68: ...2 34 NOTES SKETCHES...

Page 93: ...4V2A1563 E 3 23 FIGURE 3 6 LEVELING BASE POSITIONS AND BED TO FLOOR CLEARANCE...

Page 94: ...3 24 NOTES SKETCHES...

Page 99: ...4V2A1563 E 4 3 FIGURE 4 1 MACHINE CORE ELEMENTS...

Page 103: ...4V2A1563 E 4 7 FIGURE 4 3 MAKINO PROFESSIONAL 3 CONTROL WITH MPC5...

Page 106: ...4 10 NOTES SKETCHES...

Page 114: ...4 18 NOTES SKETCHES...

Page 123: ...4V2A1563 E 5 5 FIGURE 5 1 BASIC TROUBLESHOOTING FLOW CHART...

Page 124: ...5 6 NOTES SKETCHES...

Page 143: ...4V2A1563 E 5 25 NOTES SKETCHES...

Page 153: ...4V2A1563 E 5 35 NOTES SKETCHES...

Page 159: ...4V2A1563 E 5 41 NOTES SKETCHES...

Page 166: ...5 48 NOTES SKETCHES...

Page 191: ...4V2A1563 E 5 73 TEC F IGURE 5 26 S CHEMATIC PAGE FORMAT...

Page 197: ...4V2A1563 E 5 79 NOTES SKETCHES...

Page 198: ...5 80 NOTES SKETCHES...

Page 202: ...NOTES SKETCHES...

Page 227: ...4V2A1563 E 6 25 NOTES SKETCHES...

Page 252: ...6 50 NOTES SKETCHES...

Page 261: ...4V2A1563 E 6 59 FIGURE 6 36 SPINDLE HYDRAULIC CIRCUIT...

Page 267: ...4V2A1563 E 6 65 FIGURE 6 40 L PORT SPINDLE LUBRICATION...

Page 269: ...4V2A1563 E 6 67 FIGURE 6 41 V PORT SPINDLE LUBRICATION...

Page 277: ...4V2A1563 E 6 75 NOTES SKETCHES...

Page 279: ...4V2A1563 E 6 77 FIGURE 6 48 SEALING ROD INSTALLATION...

Page 284: ...6 82 NOTES SKETCHES...

Page 293: ...4V2A1563 E 7 5 F IGURE 7 3 AXIS DRIVE CIRCUIT...

Page 297: ...4V2A1563 E 7 9 NOTES SKETCHES...

Page 309: ...4V2A1563 E 7 21 FIGURE 7 12 BALL SCREW COOLING OIL AND TAC BEARING LUBRICATION PIPING...

Page 311: ...4V2A1563 E 7 23 NOTES SKETCHES...

Page 317: ...4V2A1563 E 7 29 FIGURE 7 18 BALL SCREW PRE TENSION PROCEDURE...

Page 346: ...7 58 NOTES SKETCHES...

Page 348: ...7 60 FIGURE 7 35 Y AXIS COVER SYSTEM...

Page 351: ...4V2A1563 E 7 63 NOTES SKETCHES...

Page 369: ...4V2A1563 E 7 81 NOTES SKETCHES...

Page 370: ...7 82 NOTES SKETCHES...

Page 374: ...NOTES SKETCHES...

Page 386: ...8 12 NOTES SKETCHES...

Page 403: ...4V2A1563 E 8 29 NOTES SKETCHES...

Page 423: ...4V2A1563 E 8 49 NOTES SKETCHES...

Page 432: ...8 58 NOTES SKETCHES...

Page 439: ...4V2A1563 E 9 5 NOTES SKETCHES...

Page 441: ...4V2A1563 E 9 7 F IGURE 9 3 OIL CONTROLLER ELECTRICAL DRAWINGS...

Page 443: ...4V2A1563 E 9 9 FIGURE 9 4 OIL CONTROLLER MACHINE SYSTEM...

Page 464: ...9 30 NOTES SKETCHES...

Page 468: ...NOTES SKETCHES...

Page 490: ...A 22 NOTES SKETCHES...

Page 525: ...4V2A1563 E A 57 NOTES SKETCHES...

Page 526: ...A 58 NOTES SKETCHES...

Page 534: ...B 6 NOTES SKETCHES...

Page 546: ...B 18 NOTES SKETCHES...

Page 558: ...B 30 NOTES SKETCHES...

Page 564: ...B 36 NOTES SKETCHES...

Page 568: ...B 40 NOTES SKETCHES...