4V2A1563 (E)

7 - 15

7.5.1

Axes Couplings

This procedure is for mounting the coupling components to the motor out-

put shaft and ball screw.

•

Following this procedure, it will be necessary to check and reset the

axis reference point, using the

CNC

Grid Shift parameters.

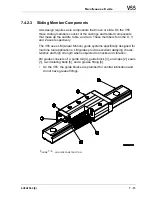

To assemble coupling (

) proceed as follows:

1. Clean and inspect all components (clamp rings, coupling, clamp ring

retainer, motor shaft, and ball screw end. Use a stone to remove any

nicks or dings, replace components if necessary or if gaulding is seen

on clamp rings.

2. Place sleeve [7] into the coupling [6].

3. Install the motor side clamp rings [4] and [5] onto sleeve [7]. Orient and

install the “male” ring [5] first and then install the “female” ring [4], as

shown.

4. Install the clamp ring retainer [3] using six (M6x25) screws [2]

.

Tighten

the screws just enough to hold the clamp rings captive, but not

compressed.

5. Install the ball screw side clamp rings [11] and [12] onto sleeve [7].

Orient and install the “male” ring [12] first and then the “female” ring

[11], as shown.

SPANN Rings

SPANN ring couplings eliminate hard-keyed shafts and allow slippage at the coupling

to minimize machine and drive component damage in the event of a “crash”. This slip-

page may change the ball screw-to-motor pulse coder relationship, changing the loca-

tion of the axis reference point, which can be corrected using the CNC Grid Shift

parameter.

F

IGURE

7-10

COUPLING

ASSEMBLY

Summary of Contents for V55

Page 6: ...vi...

Page 32: ...1 24 NOTES SKETCHES...

Page 37: ...4V2A1563 E 2 3 FIGURE 2 1 SPINDLE POWER AND TORQUE CHARACTERISTICS...

Page 39: ...4V2A1563 E 2 5 FIGURE 2 2 AXIS CONFIGURATION TRAVEL AND WORK CUBE...

Page 41: ...4V2A1563 E 2 7 FIGURE 2 4 WORKPIECE SIZE LIMITATIONS...

Page 53: ...4V2A1563 E 2 19 FIGURE 2 6 FLOOR SPACE FOR STANDARD MACHINE...

Page 58: ...2 24 F IGURE 2 7 V55 WITH 25 TOOL ATC...

Page 59: ...4V2A1563 E 2 25 F IGURE 2 8 V55 WITH 25 TOOL ATC AND LIFT UP CHIP CONVEYOR LEFT...

Page 60: ...2 26 F IGURE 2 9 V55 WITH 25 TOOL ATC AND LIFT UP CHIP CONVEYOR RIGHT...

Page 61: ...4V2A1563 E 2 27 F IGURE 2 10 V55 WITH 25 TOOL ATC LIFT UP CHIP CONVEYOR LEFT AND APC...

Page 62: ...2 28 F IGURE 2 11 V55 WITH 25 TOOL ATC LIFT UP CHIP CONVEYOR RIGHT AND APC...

Page 63: ...4V2A1563 E 2 29 F IGURE 2 12 V55 WITH 40 OR 80 TOOL ATC...

Page 64: ...2 30 F IGURE 2 13 V55 WITH 40 OR 80 TOOL ATC AND LIFT UP CHIP CONVEYOR LEFT...

Page 65: ...4V2A1563 E 2 31 F IGURE 2 14 V55 WITH 40 OR 80 TOOL ATC AND LIFT UP CHIP CONVEYOR RIGHT...

Page 66: ...2 32 F IGURE 2 15 V55 WITH 40 OR 80 TOOL ATC LIFT UP CHIP CONVEYOR LEFT AND APC...

Page 67: ...4V2A1563 E 2 33 F IGURE 2 16 V55 WITH 40 OR 80 TOOL ATC LIFT UP CHIP CONVEYOR RIGHT AND APC...

Page 68: ...2 34 NOTES SKETCHES...

Page 93: ...4V2A1563 E 3 23 FIGURE 3 6 LEVELING BASE POSITIONS AND BED TO FLOOR CLEARANCE...

Page 94: ...3 24 NOTES SKETCHES...

Page 99: ...4V2A1563 E 4 3 FIGURE 4 1 MACHINE CORE ELEMENTS...

Page 103: ...4V2A1563 E 4 7 FIGURE 4 3 MAKINO PROFESSIONAL 3 CONTROL WITH MPC5...

Page 106: ...4 10 NOTES SKETCHES...

Page 114: ...4 18 NOTES SKETCHES...

Page 123: ...4V2A1563 E 5 5 FIGURE 5 1 BASIC TROUBLESHOOTING FLOW CHART...

Page 124: ...5 6 NOTES SKETCHES...

Page 143: ...4V2A1563 E 5 25 NOTES SKETCHES...

Page 153: ...4V2A1563 E 5 35 NOTES SKETCHES...

Page 159: ...4V2A1563 E 5 41 NOTES SKETCHES...

Page 166: ...5 48 NOTES SKETCHES...

Page 191: ...4V2A1563 E 5 73 TEC F IGURE 5 26 S CHEMATIC PAGE FORMAT...

Page 197: ...4V2A1563 E 5 79 NOTES SKETCHES...

Page 198: ...5 80 NOTES SKETCHES...

Page 202: ...NOTES SKETCHES...

Page 227: ...4V2A1563 E 6 25 NOTES SKETCHES...

Page 252: ...6 50 NOTES SKETCHES...

Page 261: ...4V2A1563 E 6 59 FIGURE 6 36 SPINDLE HYDRAULIC CIRCUIT...

Page 267: ...4V2A1563 E 6 65 FIGURE 6 40 L PORT SPINDLE LUBRICATION...

Page 269: ...4V2A1563 E 6 67 FIGURE 6 41 V PORT SPINDLE LUBRICATION...

Page 277: ...4V2A1563 E 6 75 NOTES SKETCHES...

Page 279: ...4V2A1563 E 6 77 FIGURE 6 48 SEALING ROD INSTALLATION...

Page 284: ...6 82 NOTES SKETCHES...

Page 293: ...4V2A1563 E 7 5 F IGURE 7 3 AXIS DRIVE CIRCUIT...

Page 297: ...4V2A1563 E 7 9 NOTES SKETCHES...

Page 309: ...4V2A1563 E 7 21 FIGURE 7 12 BALL SCREW COOLING OIL AND TAC BEARING LUBRICATION PIPING...

Page 311: ...4V2A1563 E 7 23 NOTES SKETCHES...

Page 317: ...4V2A1563 E 7 29 FIGURE 7 18 BALL SCREW PRE TENSION PROCEDURE...

Page 346: ...7 58 NOTES SKETCHES...

Page 348: ...7 60 FIGURE 7 35 Y AXIS COVER SYSTEM...

Page 351: ...4V2A1563 E 7 63 NOTES SKETCHES...

Page 369: ...4V2A1563 E 7 81 NOTES SKETCHES...

Page 370: ...7 82 NOTES SKETCHES...

Page 374: ...NOTES SKETCHES...

Page 386: ...8 12 NOTES SKETCHES...

Page 403: ...4V2A1563 E 8 29 NOTES SKETCHES...

Page 423: ...4V2A1563 E 8 49 NOTES SKETCHES...

Page 432: ...8 58 NOTES SKETCHES...

Page 439: ...4V2A1563 E 9 5 NOTES SKETCHES...

Page 441: ...4V2A1563 E 9 7 F IGURE 9 3 OIL CONTROLLER ELECTRICAL DRAWINGS...

Page 443: ...4V2A1563 E 9 9 FIGURE 9 4 OIL CONTROLLER MACHINE SYSTEM...

Page 464: ...9 30 NOTES SKETCHES...

Page 468: ...NOTES SKETCHES...

Page 490: ...A 22 NOTES SKETCHES...

Page 525: ...4V2A1563 E A 57 NOTES SKETCHES...

Page 526: ...A 58 NOTES SKETCHES...

Page 534: ...B 6 NOTES SKETCHES...

Page 546: ...B 18 NOTES SKETCHES...

Page 558: ...B 30 NOTES SKETCHES...

Page 564: ...B 36 NOTES SKETCHES...

Page 568: ...B 40 NOTES SKETCHES...