7 - 70

7.9.3

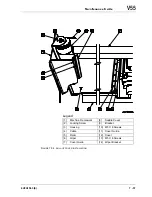

Chip Scraper Unit

The chip scraper unit is basically a built-in conveyor system used to

scrape chips from beneath the table and carry them to the back of the

machine for deposit in the chip pan or lift-up chip conveyor.

The unit consists of:

•

An AC motor

•

Two continuous chains, on each side of the unit

•

Four sprockets for driving the chains, two at front and two at rear

•

Two tensioners, one for each chain, located on front of unit

•

A series of scrapers, attached to the chains

This unit is basically maintenance free with the exception of: maintaining

proper chain tension, scraper repair or replacement, and chain alignment.

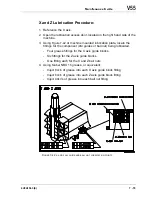

7.9.3.1

Adjusting Chain Tension

The objective in chain adjustment is to keep the chain tight to prevent it

from jumping teeth on the drive sprockets. Equal tension on both chains is

important for proper chain alignment.

To adjust chain tension, the chip scraper unit must be slid forward approx-

imately 150mm (6") to access and remove the tensioner cover.

shows the left hand chain tensioner only. The number of

screws, washers, and nuts specified in the procedure include the left and

right sides.

At the Back of the Scraper:

1. Remove the lift-up chip conveyor or chip pan, to access the back of the

chip scraper.

2. Remove the scraper motor shroud, to provide clearance for sliding the

scraper unit forward.

3. Remove the two locking screws; one on each side located near the

back end of scraper.

At the Front of Scraper:

4. Remove the three machine front covers [2], [3], and [4].

5. Loosen the two (M6) lock nuts [14] and (M6x25) side alignment screws

[13].

Summary of Contents for V55

Page 6: ...vi...

Page 32: ...1 24 NOTES SKETCHES...

Page 37: ...4V2A1563 E 2 3 FIGURE 2 1 SPINDLE POWER AND TORQUE CHARACTERISTICS...

Page 39: ...4V2A1563 E 2 5 FIGURE 2 2 AXIS CONFIGURATION TRAVEL AND WORK CUBE...

Page 41: ...4V2A1563 E 2 7 FIGURE 2 4 WORKPIECE SIZE LIMITATIONS...

Page 53: ...4V2A1563 E 2 19 FIGURE 2 6 FLOOR SPACE FOR STANDARD MACHINE...

Page 58: ...2 24 F IGURE 2 7 V55 WITH 25 TOOL ATC...

Page 59: ...4V2A1563 E 2 25 F IGURE 2 8 V55 WITH 25 TOOL ATC AND LIFT UP CHIP CONVEYOR LEFT...

Page 60: ...2 26 F IGURE 2 9 V55 WITH 25 TOOL ATC AND LIFT UP CHIP CONVEYOR RIGHT...

Page 61: ...4V2A1563 E 2 27 F IGURE 2 10 V55 WITH 25 TOOL ATC LIFT UP CHIP CONVEYOR LEFT AND APC...

Page 62: ...2 28 F IGURE 2 11 V55 WITH 25 TOOL ATC LIFT UP CHIP CONVEYOR RIGHT AND APC...

Page 63: ...4V2A1563 E 2 29 F IGURE 2 12 V55 WITH 40 OR 80 TOOL ATC...

Page 64: ...2 30 F IGURE 2 13 V55 WITH 40 OR 80 TOOL ATC AND LIFT UP CHIP CONVEYOR LEFT...

Page 65: ...4V2A1563 E 2 31 F IGURE 2 14 V55 WITH 40 OR 80 TOOL ATC AND LIFT UP CHIP CONVEYOR RIGHT...

Page 66: ...2 32 F IGURE 2 15 V55 WITH 40 OR 80 TOOL ATC LIFT UP CHIP CONVEYOR LEFT AND APC...

Page 67: ...4V2A1563 E 2 33 F IGURE 2 16 V55 WITH 40 OR 80 TOOL ATC LIFT UP CHIP CONVEYOR RIGHT AND APC...

Page 68: ...2 34 NOTES SKETCHES...

Page 93: ...4V2A1563 E 3 23 FIGURE 3 6 LEVELING BASE POSITIONS AND BED TO FLOOR CLEARANCE...

Page 94: ...3 24 NOTES SKETCHES...

Page 99: ...4V2A1563 E 4 3 FIGURE 4 1 MACHINE CORE ELEMENTS...

Page 103: ...4V2A1563 E 4 7 FIGURE 4 3 MAKINO PROFESSIONAL 3 CONTROL WITH MPC5...

Page 106: ...4 10 NOTES SKETCHES...

Page 114: ...4 18 NOTES SKETCHES...

Page 123: ...4V2A1563 E 5 5 FIGURE 5 1 BASIC TROUBLESHOOTING FLOW CHART...

Page 124: ...5 6 NOTES SKETCHES...

Page 143: ...4V2A1563 E 5 25 NOTES SKETCHES...

Page 153: ...4V2A1563 E 5 35 NOTES SKETCHES...

Page 159: ...4V2A1563 E 5 41 NOTES SKETCHES...

Page 166: ...5 48 NOTES SKETCHES...

Page 191: ...4V2A1563 E 5 73 TEC F IGURE 5 26 S CHEMATIC PAGE FORMAT...

Page 197: ...4V2A1563 E 5 79 NOTES SKETCHES...

Page 198: ...5 80 NOTES SKETCHES...

Page 202: ...NOTES SKETCHES...

Page 227: ...4V2A1563 E 6 25 NOTES SKETCHES...

Page 252: ...6 50 NOTES SKETCHES...

Page 261: ...4V2A1563 E 6 59 FIGURE 6 36 SPINDLE HYDRAULIC CIRCUIT...

Page 267: ...4V2A1563 E 6 65 FIGURE 6 40 L PORT SPINDLE LUBRICATION...

Page 269: ...4V2A1563 E 6 67 FIGURE 6 41 V PORT SPINDLE LUBRICATION...

Page 277: ...4V2A1563 E 6 75 NOTES SKETCHES...

Page 279: ...4V2A1563 E 6 77 FIGURE 6 48 SEALING ROD INSTALLATION...

Page 284: ...6 82 NOTES SKETCHES...

Page 293: ...4V2A1563 E 7 5 F IGURE 7 3 AXIS DRIVE CIRCUIT...

Page 297: ...4V2A1563 E 7 9 NOTES SKETCHES...

Page 309: ...4V2A1563 E 7 21 FIGURE 7 12 BALL SCREW COOLING OIL AND TAC BEARING LUBRICATION PIPING...

Page 311: ...4V2A1563 E 7 23 NOTES SKETCHES...

Page 317: ...4V2A1563 E 7 29 FIGURE 7 18 BALL SCREW PRE TENSION PROCEDURE...

Page 346: ...7 58 NOTES SKETCHES...

Page 348: ...7 60 FIGURE 7 35 Y AXIS COVER SYSTEM...

Page 351: ...4V2A1563 E 7 63 NOTES SKETCHES...

Page 369: ...4V2A1563 E 7 81 NOTES SKETCHES...

Page 370: ...7 82 NOTES SKETCHES...

Page 374: ...NOTES SKETCHES...

Page 386: ...8 12 NOTES SKETCHES...

Page 403: ...4V2A1563 E 8 29 NOTES SKETCHES...

Page 423: ...4V2A1563 E 8 49 NOTES SKETCHES...

Page 432: ...8 58 NOTES SKETCHES...

Page 439: ...4V2A1563 E 9 5 NOTES SKETCHES...

Page 441: ...4V2A1563 E 9 7 F IGURE 9 3 OIL CONTROLLER ELECTRICAL DRAWINGS...

Page 443: ...4V2A1563 E 9 9 FIGURE 9 4 OIL CONTROLLER MACHINE SYSTEM...

Page 464: ...9 30 NOTES SKETCHES...

Page 468: ...NOTES SKETCHES...

Page 490: ...A 22 NOTES SKETCHES...

Page 525: ...4V2A1563 E A 57 NOTES SKETCHES...

Page 526: ...A 58 NOTES SKETCHES...

Page 534: ...B 6 NOTES SKETCHES...

Page 546: ...B 18 NOTES SKETCHES...

Page 558: ...B 30 NOTES SKETCHES...

Page 564: ...B 36 NOTES SKETCHES...

Page 568: ...B 40 NOTES SKETCHES...