7

Use of nozzle assembly

Use of the special nozzle assembly will minimize chip

scatter, making for a work area.

(Fig. 6)

The nozzle assembly may be attached after the chip

cover on the tool body is removed. Use the chip cover

screws to fasten it in place.

(Fig. 7)

OPERATION

CAUTION:

• Hold the tool firmly with one hand on the knob and the

other hand on the switch handle when performing the

tool.

Planing operation (Fig. 8)

First, rest the tool front base flat upon the workpiece

surface without the blades making any contact. Switch on

and wait until the blades attain full speed. Then move the

tool gently forward. Apply pressure on the front of tool at

the start of planing, and at the back at the end of planing.

Planing will be easier if you incline the workpiece in

stationary fashion, so that you can plane somewhat

downhill.

The speed and depth of cut determine the kind of finish.

The power planer keeps cutting at a speed that will not

result in jamming by chips. For rough cutting, the depth of

cut can be increased, while for a good finish you should

reduce the depth of cut and advance the tool more slowly.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

• Never use gasoline, benzine, thinner, alcohol or the

like. Discoloration, deformation or cracks may result.

Sharpening the planer blades

Always keep your blades sharp for the best performance

possible. Use the sharpening holder to remove nicks and

produce a fine edge.

(Fig. 9)

First, loosen the two wing nuts on the holder and insert

the blades (A) and (B), so that they contact the sides (C)

and (D). Then tighten the wing nuts.

(Fig. 10)

Immerse the dressing stone in water for 2 or 3 minutes

before sharpening. Hold the holder so that the both blades

contact the dressing stone for simultaneous sharpening at

the same angle.

(Fig. 11)

Replacing carbon brushes

Remove and check the carbon brushes regularly. Replace

when they wear down to the limit mark. Keep the carbon

brushes clean and free to slip in the holders. Both carbon

brushes should be replaced at the same time. Use only

identical carbon brushes.

(Fig. 12)

Use a screwdriver to remove the chip cover.

(Fig. 13)

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps.

(Fig. 14)

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized Service Centers, always

using Makita replacement parts.

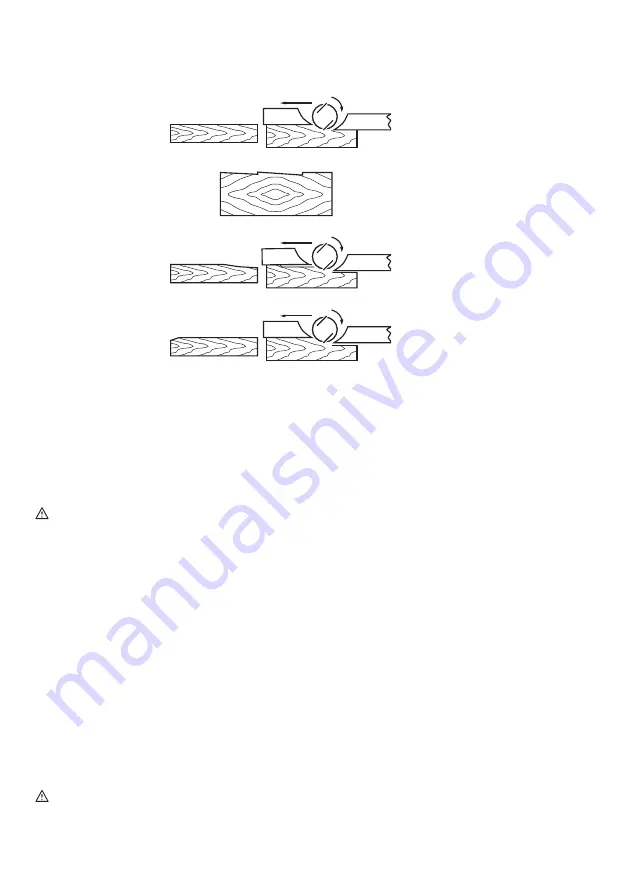

(A) Front base (Movable shoe)

(B) Rear base (Stationary shoe)

Correct setting

Nicks in surface

Gouging at start

Gouging at end

Although this side view cannot show it,

the edges of the blades run perfectly

parallel to the rear base surface.

Cause: One or both blades fails to have

edge parallel to rear base line.

Cause: One or both blade edges fails to

protrude enough in relation to

rear base line.

Cause: One or both blade edges

protrudes too far in relation to

rear base line.

EN0004-1

(A)

(B)

(B)

(A)

(B)

(A)