D

isassembly and assembly

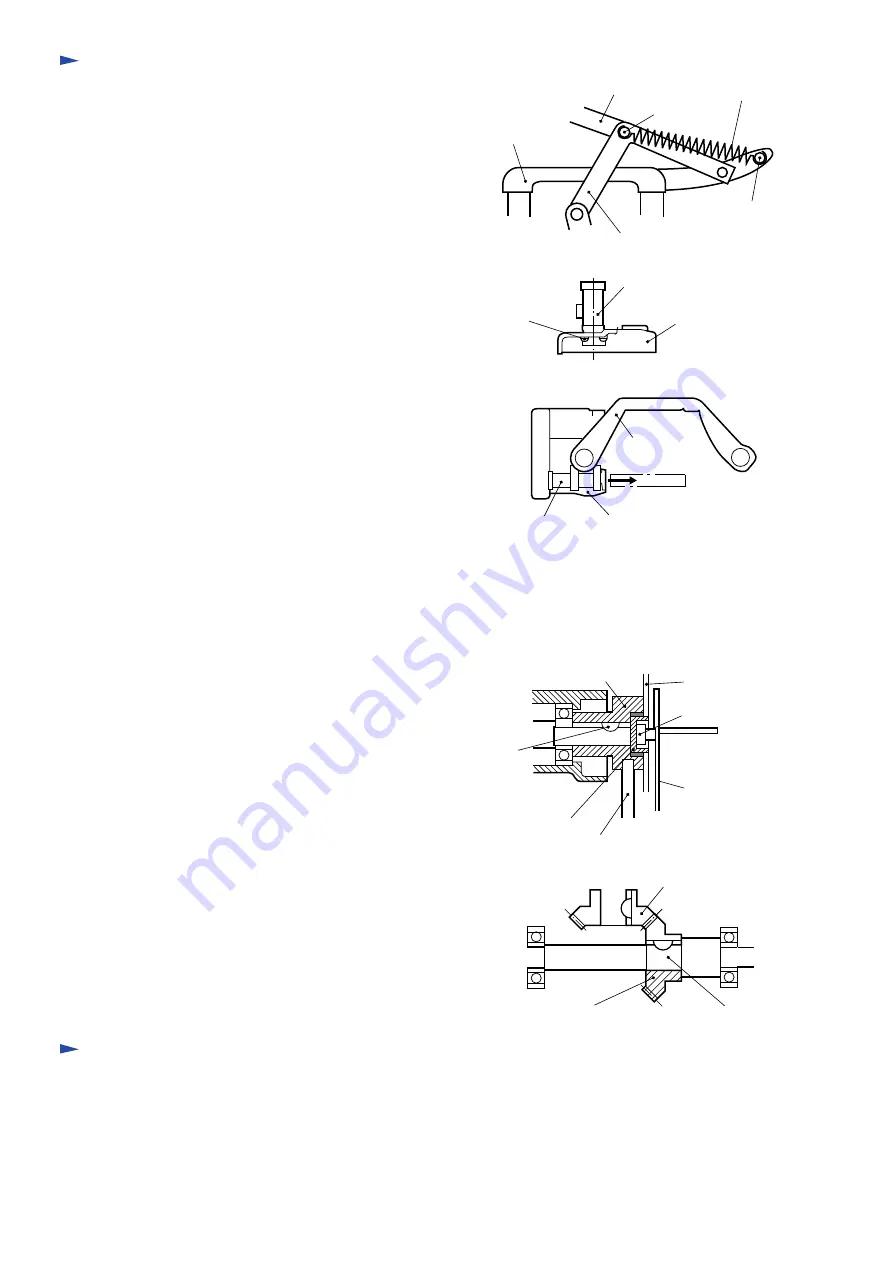

Remove stepped pins that connect lever pipe and

rink plate. Turn lever pipe to the right side of the

tension spring until it stops and remove the tension

spring. When hanging a tension spring, direction of

hook should be as shown in the figure.

1)

A

djustment of saw blade

When a diameter of vertical saw becomes small because of grinding, insert a bar into the outer hole

of the vertical saw flange and stop the rotation. Use wrench 4-13 and turn hex. bolt in the rear side

of the lateral saw shaft to move the vertical saw forward and backward, and align the lateral saw to

the tip of the vertical saw. In the case of the ground lateral saw, make adjustment by moving the

lateral saw's gear case right and left.

1)

Remove four cross-slot pan-head screws inside the

center gear housing, and disassemble vertical saw

support and center gear housing.

2)

Lever pipe

Stepped pin

Pole supporter

Tension spring

Stepped pin

Link plate

Remove gear housing of lateral saw section from the

vertical saw support, and bevel gear of the lateral

saw side will be disengaged. Separate saw blade

shaft from vertical saw support, and the vertical saw

shaft can be removed from the bevel gear.

6)

Insert a bar into the outer hole of inner flange and

remove hex. socket bolt by using a wrench so that

both inner flange 50 and flange 25 can be removed

from saw blade shaft.

5)

Replacement of carbon brush

Fully open the lever 240 outside and remove holder cap from the rear cover's hole by using a screwdriver

then remove the carbon brush.

4)

Remove spring pin that connects slide pipe and vertical

saw support and pull out the slide pipe to the direction

as shown in the figure, then disassemble the slide

frame and vertical saw support.

3)

Vertical saw support

Center gear housing

Cross-slot

pan-head screw

Slide frame

Vertical saw support

Slide pipe

Inner flange 50

Bar

Flange 25

Woodruff

key

Vertical saw

Hex. socket bolt

Wrench

Vertical saw's bevel gear

Saw blade

Vertical saw shaft bevel gear

Inner flange 50 of vertical shaft