5

FUNCTIONAL

DESCRIPTION

CAUTION:

•

Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

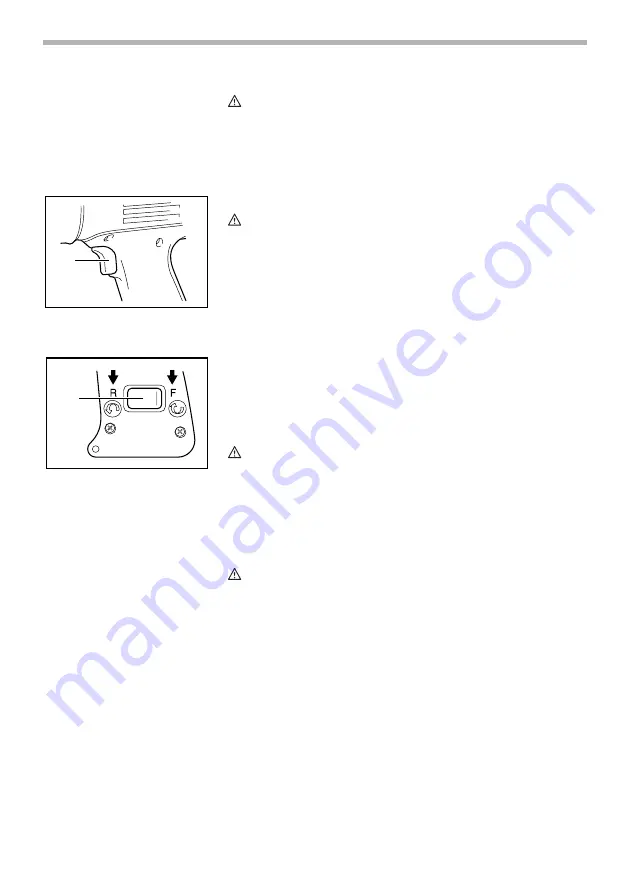

Switch action

CAUTION:

•

Before plugging in the tool, always check to see that the

switch trigger actuates properly and returns to the “OFF”

position when released.

To start the tool, simply pull the switch trigger. Release the

switch trigger to stop.

Reversing switch action

This tool has a reversing switch to change the direction of

rotation. Press the right side of the reversing switch for clock-

wise rotation or the left side of the reversing switch for coun-

terclockwise rotation.

CAUTION:

•

Always check the direction of rotation before operation.

•

Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation before

the tool stops may damage the tool.

ASSEMBLY

CAUTION:

•

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Selecting correct socket

Always use the correct size socket for bolts and nuts. An

incorrect size socket will result in inaccurate and inconsistent

fastening torque and/or damage to the bolt or nut.

1. Switch trigger

1

002313

1. Reversing switch

1

002323