7

Hold the tool firmly and place the socket over the bolt or nut.

Turn the tool on and fasten for the proper fastening time.

NOTE:

•

Hold the tool pointed straight at the bolt or nut.

•

Excessive fastening torque may damage the bolt/nut or

socket. Before starting your job, always perform a test

operation to determine the proper fastening time for your

bolt or nut.

The fastening torque is affected by a wide variety of factors

including the following. After fastening, always check the

torque with a torque wrench.

1. Voltage

Voltage drop will cause a reduction in the fastening

torque.

2. Socket

•

Failure to use the correct size socket will cause a

reduction in the fastening torque.

•

A worn socket ( wear on the hex end or square end )

will cause a reduction in the fastening torque.

3. Bolt

•

Even though the torque coefficient and the class of

bolt are the same, the proper fastening torque will

differ according to the diameter of bolt.

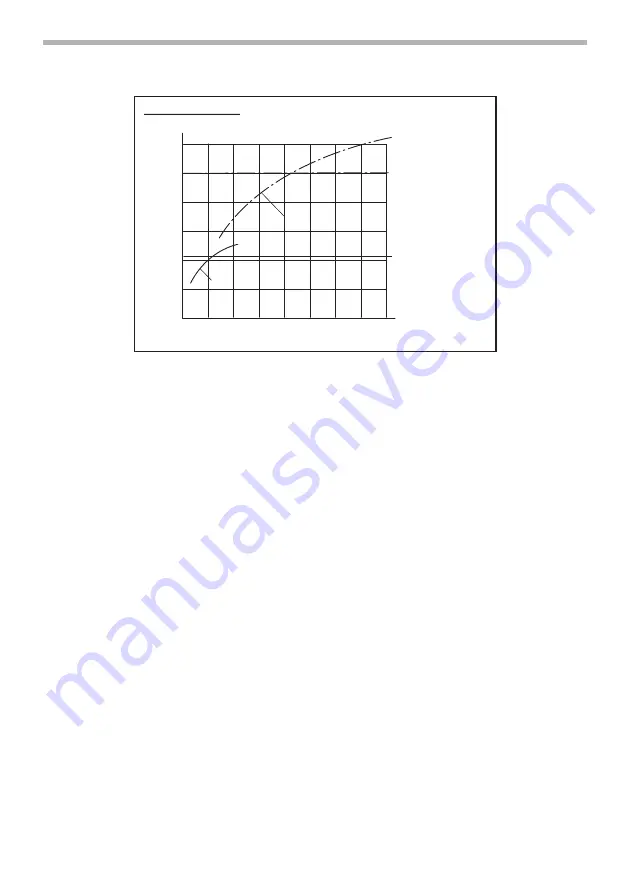

N.m

(ft.lbs)

200

(144)

250

(181)

300

(217)

150

(108)

100

(72)

50

(36)

0

1

2

3

4

5

6

7

8

(S)

M16X50 (5/8” X 2”)

M12X50 (7/16” X 2”)

M16 (5/8”)

M12 (7/16”)

Fastening time

F

astening torque

Proper f

astening torque

High tensile bolt