DISASSEMBLING

[3] DISASSEMBLY/ASSEMBLY

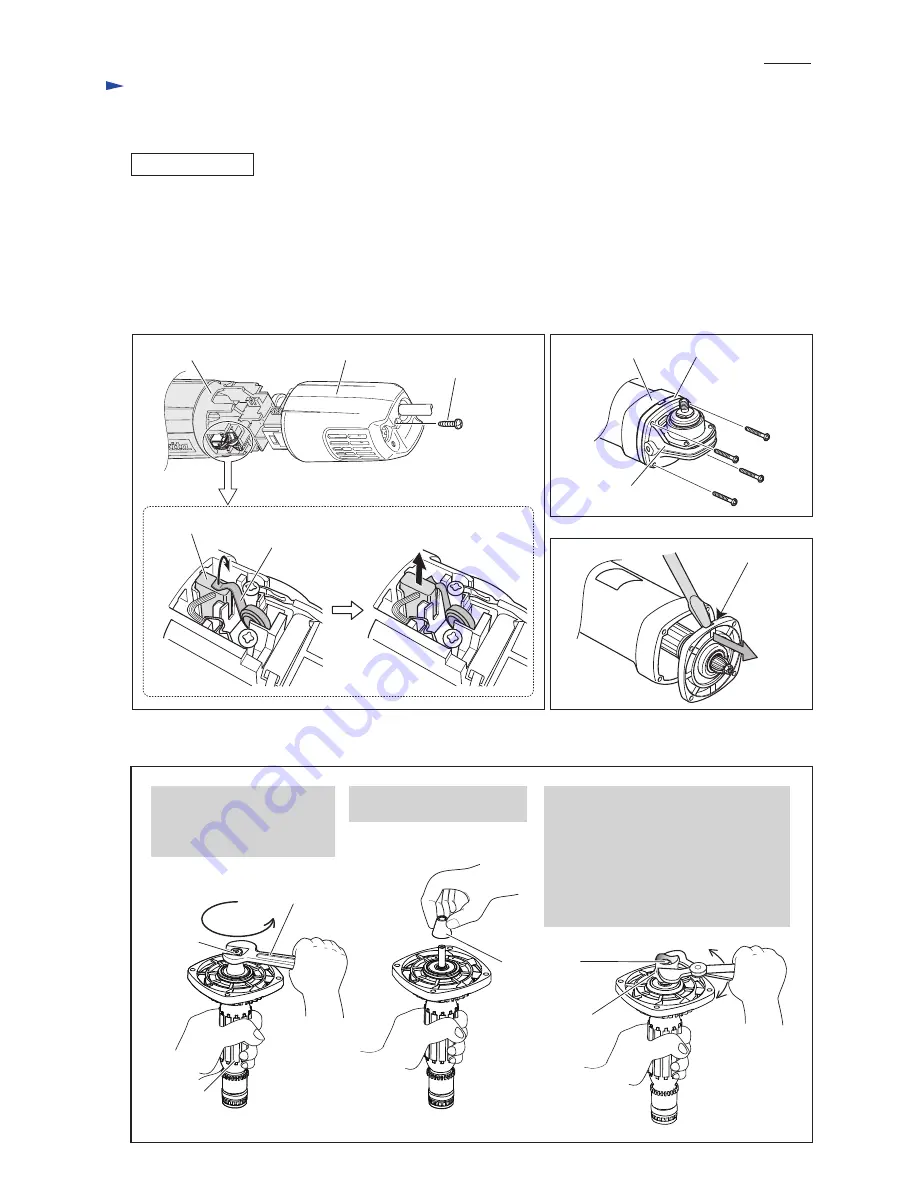

[3] -1. Replacing Spiral Bevel Gear 10

Fig. 4

Fig. 5

Fig. 2

Fig. 3

Spiral spring of

Brush holder

Carbon brush

Motor housing

Rear cover

4x18 Tapping screw

Gear housing

Motor housing

Gear housing cover

notch

(1) Separate Rear cover from Motor housing by removing 4x18 Tapping screw, then disconnect Carbon brush from

the commutator of Armature by moving the tail end of the spiral spring of Brush holder as drawn below. (

Fig. 2

)

Note

: No need to remove Carbon brushes in this step.

(2) Remove Gear housing by unscrewing four 4x30 Tapping screws. (

Fig. 3

)

(3) Remove Gear housing cover from Motor housing together with Armature by levering with a slotted screwdriver fit to

the notch on the Gear housing cover. (

Fig. 4

)

(4) Remove Spiral bevel gear (small) from Armature. (

Fig. 5

)

Armature

Wrench 10

1. Remove M6 Hex nut that

fastens Spiral bevel gear 10

by turning it counter-

clockwise with a wrench 10.

2. Pull off Spiral bevel gear 10

by hand.

Spiral bevel

gear 10

Cloth to protect

Spiral bevel gear 10

M6

Hex nut

Note

: If it is difficult to remove by hand,

take the following step.

1. Lubricate the gear and Armature shaft

with spray lubricant.

2. Wrap the gear with a cloth to protect

the gear teeth.

3. Remove the gear by turning it with

a water pump pliers.

P

3

/

8

R

epair