Fig. 6

Notch

Switch lever

Spindle

Name plate

Assemble by reversing the disassembly procedure.

(Refer to

Figs. 5, 4, 3 and 2)

Note

: Assemble Gear housing cover together with Armature

while facing its notch to the same side as Name plate. (

Fig. 6

)

And then, assemble Gear housing while facing Spindle to the

same side as the notch and Name plate. (

Fig. 6

)

ASSEMBLING

P

4

/

8

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Replacing Spiral Bevel Gear 10 (cont.)

Note

: The gear and the ball bearing can be replaced without disassembling the motor section.

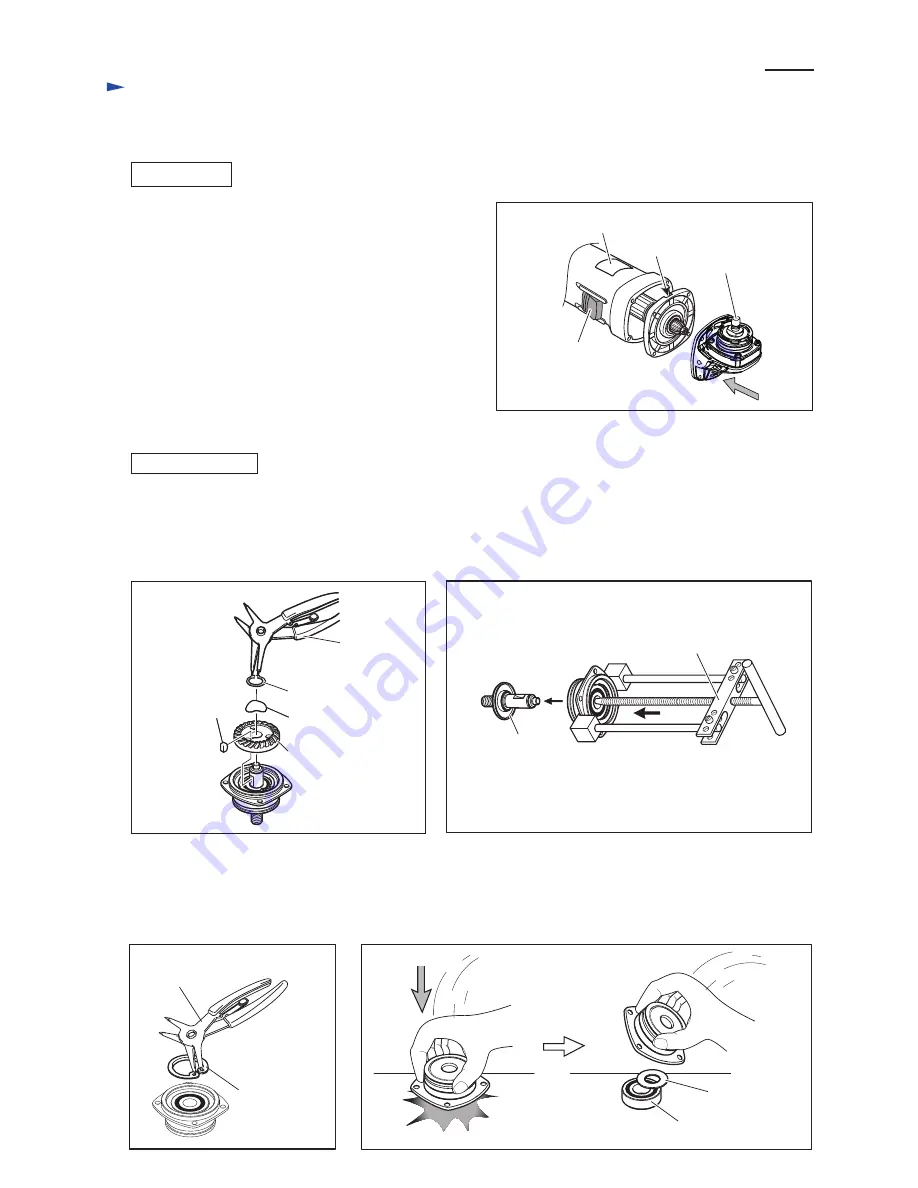

(1) Remove Retaining ring S-12 with 1R291, then remove Wave washer 12. Spiral bevel gear (large) can be removed

from Spindle by hand. And then, remove Woodruff key 4 from Spindle. (

Fig. 7

)

(2) Remove Spindle from Bearing box using 1R045. (

Fig. 8

)

[3] -2. Replacing Spiral Bevel Gear 37 and Ball Bearing 6201DDW

DISASSEMBLING

Fig. 7

Fig. 8

Retaining ring S-12

Wave washer 12

1R291

Spiral bevel gear 37

Woodruff key 4

Spindle with

Labyrinth Ring

1R045

Fig. 9

Fig. 10

Retaining ring

R-32

1R291

Ball bearing

6201DDW

Flat washer 12

(3) Remove retaining ring R-32 with 1R291. (

Fig. 9

)

(4) Remove Ball bearing 6201DDW together with Flat washer 12 from Bearing box by tapping Bearing box straight down

against workbench. (

Fig. 10

)

Note

: If it is difficult to remove it by hand tapping, use arbor press.