P

5

/

8

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Replacing large Spiral Bevel Gear and Ball Bearing 6201DDW (cont.)

ASSEMBLING

Assemble by reversing the disassembly procedure.

Note :

•

Do not forget to put Flat washer 12 in Bearing box. (Refer to

Fig. 10

.)

•

Be careful not to deform Labyrinth ring 19 when assembling to Spindle.

•

Referring to

Fig. 7

, assemble Woodruff key 4, Spiral bevel gear (large) and Wave washer 12 to Spindle.

Then, assemble Retaining ring S-12 using 1R291 by fitting exactly to the groove on Spindle’s drum with snap.

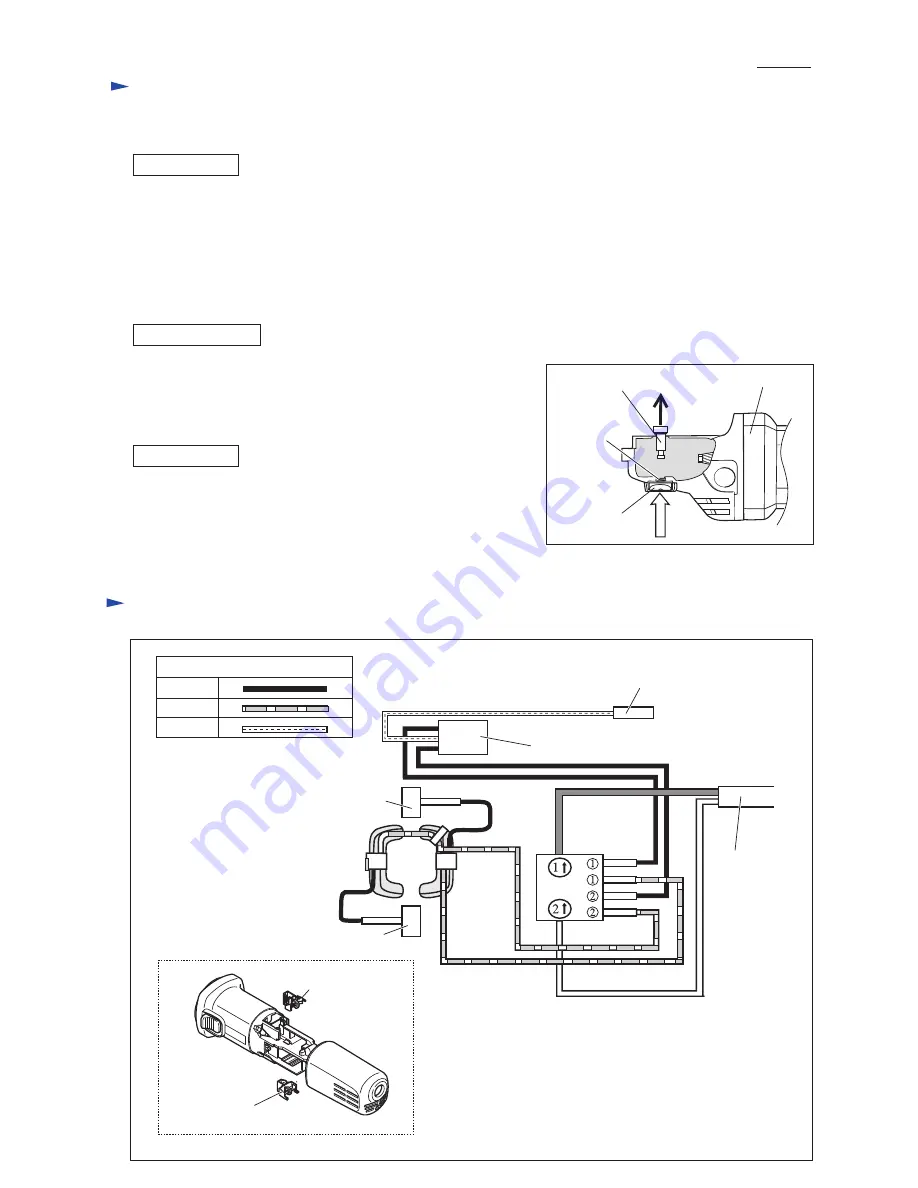

[3] -3. Disassembling/Assembling Shaft Lock Mechanism

(1) Remove Bearing box from Gear housing.

(2) Pull off Shoulder pin 4 with pliers while pushing Pin cap with

finger. (

Fig. 11

)

Note

: Do not pull off Shoulder pin 4 without holding Pin cap

because Compression spring 8 would sling Pin cap.

Push Shoulder pin 4 through Gear housing and

Compression spring 8 into Pin cap.

Note

: Do not reuse removed Pin cap because removal of Shoulder

Pin 4 damages the inside surface of Pin cap, producing plastic dust.

Therefore, be sure to use a new Pin cap for replacement and to remove

all the plastic dust on Shoulder pin 4.

DISASSEMBLING

ASSEMBLING

Fig. D-1

Fig. 11

Pin cap

Gear housing

Shoulder pin 4

Compression

spring 8

C

ircuit diagram

Red

Clear

Color index of lead wires' sheath

Black

Brush holder A

Brush holder A

Noise suppressor*

Earth terminal (Ground terminal)

on the lead wire of Noise suppressor

Power supply

cord

Brush holder B

Brush holder B

Field

Switch

*noise suppressor is not used for some countries.