P 2 / 10

[2] LUBRICATION

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Armature, Spiral Bevel Gear 11

Apply Makita grease SG No.00 to the portions designated with the black triangle, and apply Molybdenum

disulfide lubricant to the portions designated with gray triangle to protect parts and product from unusual abrasion.

[1] NECESSARY REPAIRING TOOLS

CAUTION: Unplug the machine and remove the wheel, the wheel cover, the inner flange and

the outer flange from the machine for safety before repair/ maintenance in

accordance with the instruction manual!

Fig. 1

Fig. 2

Fig. 3

R

epair

DISASSEMBLY

Description

Code No.

Use for

Item No.

Description

Portion to lubricate

1R217

Ring 22

Holding Bearing box when removing Spiral bevel gear 38

Holding Gear housing complete when removing Pin for shaft lock

1R268

1R269

1R291

Spring pin extractor M3

Removing Pin for shaft lock

Removing Ball bearing 627DDW from Armature shaft

Removing / Assembling Retaining ring S-12 from / to Armature shaft

Removing / Assembling Bearing retainer

Bearing extractor

Retaining ring S and R pliers

1R340

Bearing retainer wrench

1R350

Ring 60

8

3

6

3

6

8

Gear housing complete

Spiral bevel gear 11

Lock spring 12

Gear room: Apply approx. 15g.

Inside

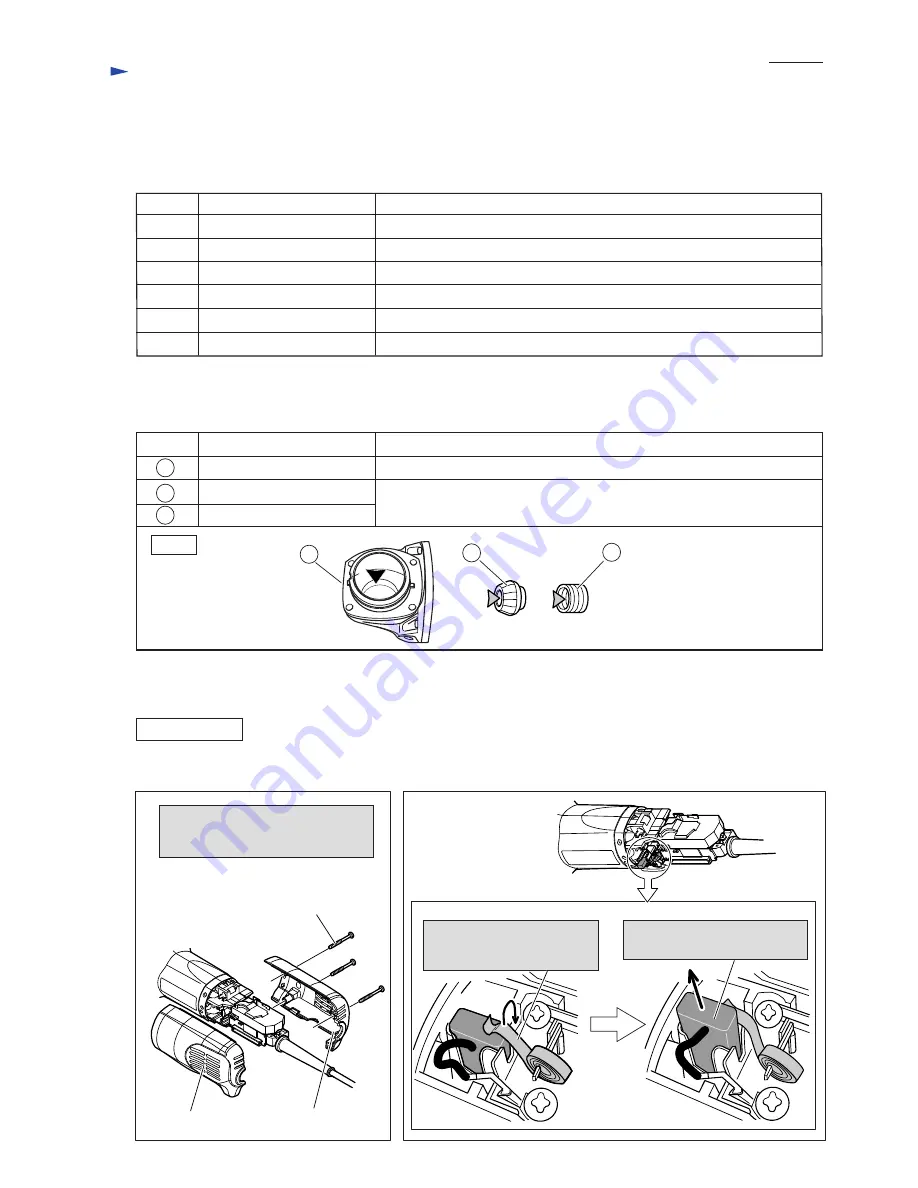

Shift the tail of Spiral spring

from the top of Carbon brush to

the side notch of Brush holder.

Disconnect the Carbon brush from

Armature's commutator by pulling.

Rear cover (L)

Rear cover (R)

4x40 Tapping screw: 3 pcs.

Disassemble Rear cover (L and R)

from Motor housing by unscrewing

4x40 Tapping screws.

(1) Disconnect Carbon brush from Armature's commutator as illustrated in Figs. 2 and 3.