8

010479

CAUTION:

• If the tool is operated continuously at low speeds for a

long time, the motor will get overloaded and heated up.

• The speed adjusting dial can be turned only as far as 5

and back to 1. Do not force it past 5 or 1, or the speed

adjusting function may no longer work.

The tools equipped with electronic function are easy to

operate because of the following features.

• Electronic constant speed control

Possible to get fine finish, because the rotating speed

is kept constantly even under the loaded condition.

• Soft start feature

Soft start because of suppressed starting shock.

• Overload protector

When the tool would be employed over the admissible

load, it will stop automatically to protect the motor and

wheel. When the load will come to the admissible level

again, the tool can be started automatically.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing side grip (handle) (Fig. 4 & 5)

Remove one of the screws which secure gear housing

and head cover, then screw the side grip on the tool.

CAUTION:

• Always be sure that the side grip is installed securely

before operation.

Installing or removing abrasive disc (Fig. 6 & 7)

Remove all dirt or foreign matter from the pad.

Screw the pad onto the spindle with pressing the shaft

lock.

Attach the disc to the pad so carefully that the edges of

disc and pad overlap each other without protruding.

To remove the abrasive disc, pull off its edge from the

pad.

IF USED AS A GRINDER

Removing head cover (Fig. 8 & 9)

When use as a grinder, remove the head cover. Loosen

the screws and pull off the head cover while pulling out its

corners.

Installing side grip (handle) (Fig. 10)

CAUTION:

• Always be sure that the side grip is installed securely

before operation.

Screw the side grip securely on the position of the tool as

shown in the figure.

Installing or removing wheel guard

(For depressed center wheel, multi disc /

abrasive cut-off wheel, diamond wheel)

For tool with locking screw type wheel guard (Fig. 11)

WARNING:

• When using a depressed center grinding wheel/Multi-

disc, flex wheel or wire cup brush, the wheel guard

must be fitted on the tool so that the closed side of the

guard always points toward the operator.

• When using an abrasive cut-off / diamond wheel, be

sure to use only the special wheel guard designed for

use with cut-off wheels. (In some European countries,

when using a diamond wheel, the ordinary guard can

be used. Follow the regulations in your country.)

Mount the wheel guard with the protrusion on the wheel

guard band aligned with the notch on the bearing box.

Then rotate the wheel guard around 180 degrees coun-

terclockwise. Be sure to tighten the screw securely.

To remove wheel guard, follow the installation procedure

in reverse.

Installing or removing depressed center grinding

wheel/Multi-disc (accessory)

Mount the inner flange onto the spindle. Fit the wheel/

disc on the inner flange and screw the lock nut onto the

spindle.

(Fig. 12)

To tighten the lock nut, press the shaft lock firmly so that

the spindle cannot revolve, then use the lock nut wrench

and securely tighten clockwise.

To remove the wheel, follow the installation procedure in

reverse.

(Fig. 13)

Installing or removing abrasive disc (optional

accessory) (Fig. 14)

NOTE:

• Use sander accessories specified in this manual.

These must be purchased separately.

Mount the rubber pad onto the spindle. Fit the disc on the

rubber pad and screw the lock nut onto the spindle. To

tighten the lock nut, press the shaft lock firmly so that the

spindle cannot revolve, then use the lock nut wrench and

securely tighten clockwise.

To remove the disc, follow the installation procedure in

reverse.

OPERATION

WARNING:

• It should never be necessary to force the tool. The

weight of the tool applies adequate pressure. Forcing

and excessive pressure could cause dangerous wheel

breakage.

• ALWAYS replace wheel if tool is dropped while grinding.

• NEVER bang or hit grinding disc or wheel onto work.

• Avoid bouncing and snagging the wheel, especially

when working corners, sharp edges etc. This can

cause loss of control and kickback.

• NEVER use tool with wood cutting blades and other

sawblades. Such blades when used on a grinder fre-

quently kick and cause loss of control leading to per-

sonal injury.

CAUTION:

• After operation, always switch off the tool and wait until

the wheel has come to a complete stop before putting

the tool down.

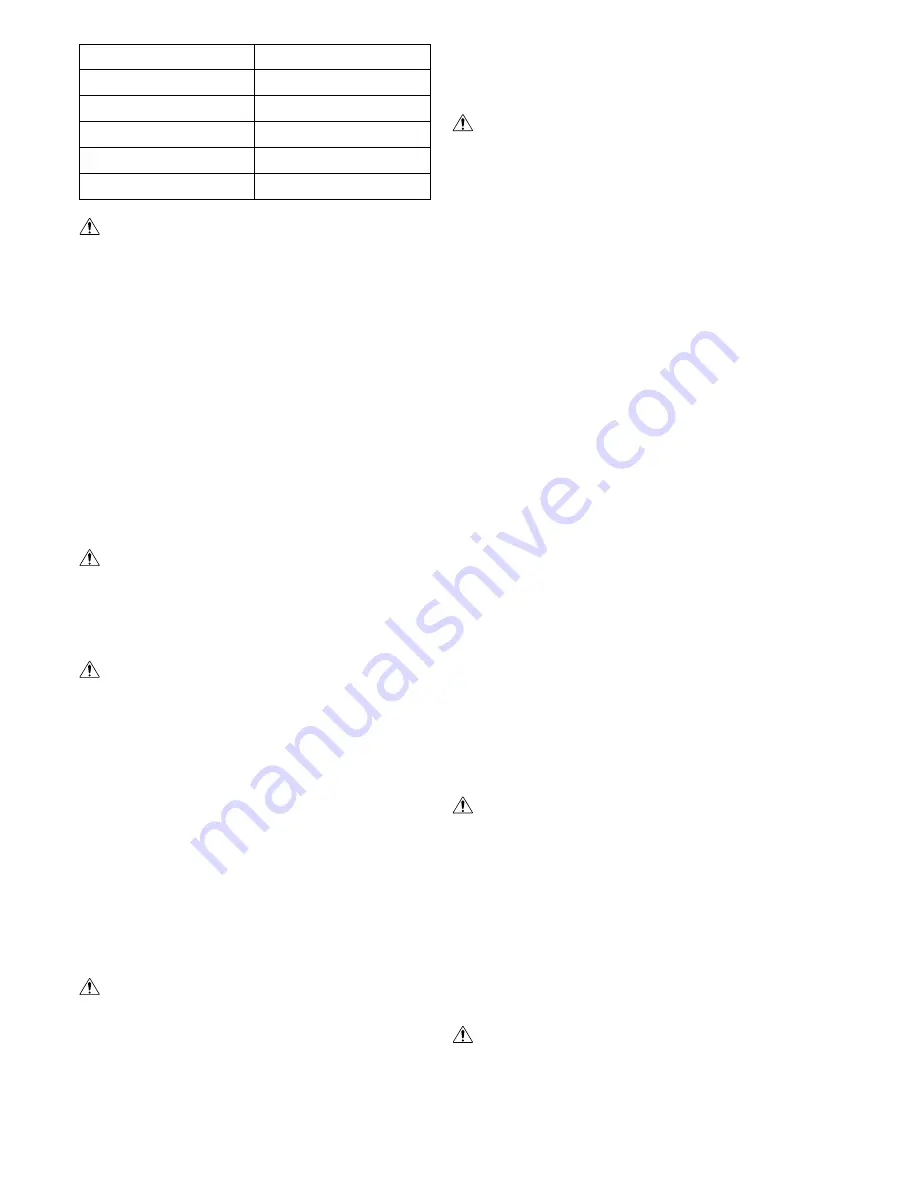

Number min

–1

(R.P.M.)

1

2,000

2

3,000

3

4,500

4

6,000

5

7,800