8

Loading the nailer

CAUTION:

•

Make sure that the coil support plate is set to the

correct step for used nails.

Fig.8

Disconnect the air hose from the tool. Select nails

suitable for your work. Depress the latch lever and open

the door and magazine cap.

Select nails suitable for your work. Depress the latch

lever and open the magazine cap.

Lift and turn the coil support plate so that the arrow with

nail size indicated on the coil support plate will point to

the corresponding graduation increment marked on the

magazine. If the tool is operated with the coil support

plate set to the wrong step, poor nail feed or malfunction

of the tool may result.

Fig.9

Place the nail coil over the coil support plate. Uncoil

enough nails to reach the feed claw. Place the first nail in

the driver channel and the second nail in the feed claw.

Place other uncoiled nails on feeder body. Close the

magazine cap slowry until it lock after checking to see

that the nail coil is set properly in the magazine.

Fig.10

Connecting air hose

Slip the air socket of the air hose onto the air fitting on

the nailer. Be sure that the air socket locks firmly into

position when installed onto the air fitting. A hose

coupling must be installed on or near the tool in such a

way that the pressure reservoir will discharge at the time

the air supply coupling is disconnected.

OPERATION

CAUTION:

•

Make sure all safety systems are in working order

before operation.

1.

To drive a nail, you may place the contact element

against the workpiece and pull the trigger, or

Fig.11

Fig.12

2. Pull the trigger first and then place the contact

element against the workpiece.

•

No. (1) method is for intermittent nailing, when you

wish to drive a nail carefully and very accurately.

No. (2) method is for continuous nailing.

CAUTION:

•

However when the tool is set to the "Intermittent

Nailing" mode, WITH THE TRIGGER HELD IN A

HALF-PULLED POSITION, an unexpected nailing

could occur, if contact element is allowed to

re-contact against the workpiece or the other

surface under the influence of recoil.

In order to avoid this unexpected nailing, perform

as follows;

−

A. Do not place the contact element against the

workpiece with excessive force.

−

B. Pull the trigger fully and hold it on for 1-2

seconds after nailing.

•

For No. (1) method, set the change lever to

the

position.

For No. (2) method, set the change lever to

the

position.

After using the change lever to change the nailing

method, always make sure that the change lever is

properly set to the position for the desired nailing

method.

Fig.13

Fig.14

Nailing of steel plate

WARNING:

•

Use 2.3 mm or les steel for C-shaped one.

The tool will bounce severely and a nail struck

back, causing serious injuries.

•

Use hardened nails only for steel plate.

Using other purposed nails may cause serious

injuries.

•

When nailing, hold the tool so that it stands upright

to the driving surface.

Slanted nailing may cause nails to strike back,

causing serious injuries.

•

When fastening a corrugated zinc plate on the

C-shaped steel, use 0.7 mm or less thick plate and

32 mm long hardened nails. Failure to do so may

cause nails to strike back, causing serious injuries.

•

Do not use the tool for nailing on ceiling or roof.

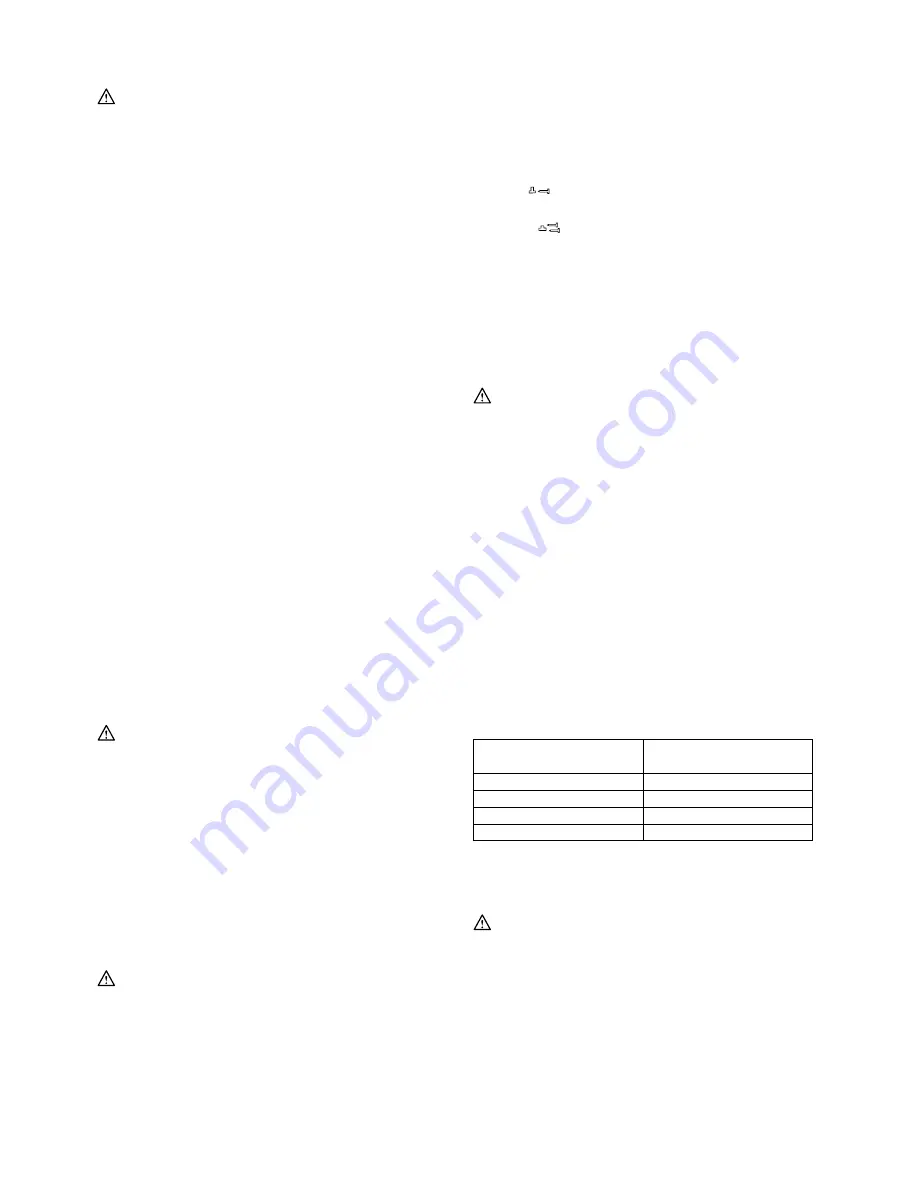

Choose and use nails more than 10 mm longer than total

thickness of all workpiece to be fastened by referring to

the table below.

1

.

8

-

22

10

-

27

1

5-

30

1

5-

38

32

38

45

5

0

Mater

i

a

l

th

i

c

k

nes

(mm)

N

a

il l

ength

(mm)

009186

Fig.15

Fig.16

CAUTION:

•

Depending on the hardness and total thickness of

all workpiece in combination to be fastened,

enough fastening may not be obtained. Nailing on

steel plate to excessive depth may extremely

reduce the fastening force. Before nailing, adjust

the nailing depth properly.

•

In the nailing on the steel plate, the driver may be

clogged due to susceptibility to wear. When it is

worn, sharpen it or replace it with a new one.

Summary of Contents for AN610H

Page 62: ...62 ...

Page 63: ...63 ...

Page 64: ...64 Makita Corporation Anjo Aichi Japan 884844B977 ...