9

Nailing of concrete

WARNING:

•

Use hardened nails only for concrete.

Using other purposed nails may cause serious

injuries.Do not nail directly on the concrete or do

not use to fasten directly the steel plate to the

concrete. Failure to do so may cause concrete

fragments to fly off or nails to strike back, causing

serious injuries.

•

When nailing, hold the tool so that it stands upright

to the driving surface.

Slanted nailing may cause concrete fragments to

fly off or nails to strike back, causing serious

injuries.

•

Do not use on the surface that objects hang from,

such as area where hangers for sewer pipe, dust

pipe etc. are set up

Choose and use nails so that the penetration amount

into concrete ranges 10 mm - 15 mm by referring to the

table below.

20

2

5

30

3

5

32

38

45

5

0

A

ppro

x.

12

A

ppro

x.

13

A

ppro

x.

1

5

A

ppro

x.

1

5

W

oo

d

th

i

c

k

ness

N

a

il l

ength

(mm)

(mm)

(mm)

Concrete

009189

Fig.17

CAUTION:

•

Use this tool only for soft concrete built up not so

long before. Using on the hard concrete may cause

nail bending or nailing to insufficient depth.

•

When the penetration amount into concrete comes

to more than 15 mm, nailing to the sufficient length

may not be obtained.

Cutting off the sheet

Fig.18

CAUTION:

•

Always disconnect the hose before cutting off the

sheet.

Tear off the output sheet in the direction of the arrow

when using the sheet collated nails.

MAINTENANCE

CAUTION:

•

Always disconnect the air hose from the tool before

attempting to perform inspection or maintenance.

Jammed nailer

Fig.19

Fig.20

CAUTION:

•

Always disconnect the air hose and remove the

nails from the magazine before cleaning a jam.

When the nailer becomes jammed, do as follows:

Open the magazine cap and remove the nail coil. Insert

a small rod or the like into the ejection port and tap it with

a hammer to drive out the nail jamming from the ejection

port. Reset the nail coil and close the magazine cap.

Drain tool

Remove the hose from the tool. Place the tool so that

the air fitting faces down to the floor. Drain as much as

possible.

Cleaning of tool

Iron dust that adhere to the magnet can be blown off by

using an air duster.

Cap

When not in use, disconnect the hose. Then cap the air

fitting with the cap.

Fig.21

Storage

When not in use, the nailer should be stored in a warm

and dry place.

Maintenance of compressor, air set and air hose

Fig.22

Fig.23

After operation, always drain the compressor tank and

the air filter. If moisture is allowed to enter the tool, It

may result in poor performance and possible tool failure.

Check regularly to see if there is sufficient pneumatic oil

in the oiler of the air set. Failure to maintain sufficient

lubrication will cause O-rings to wear quickly.

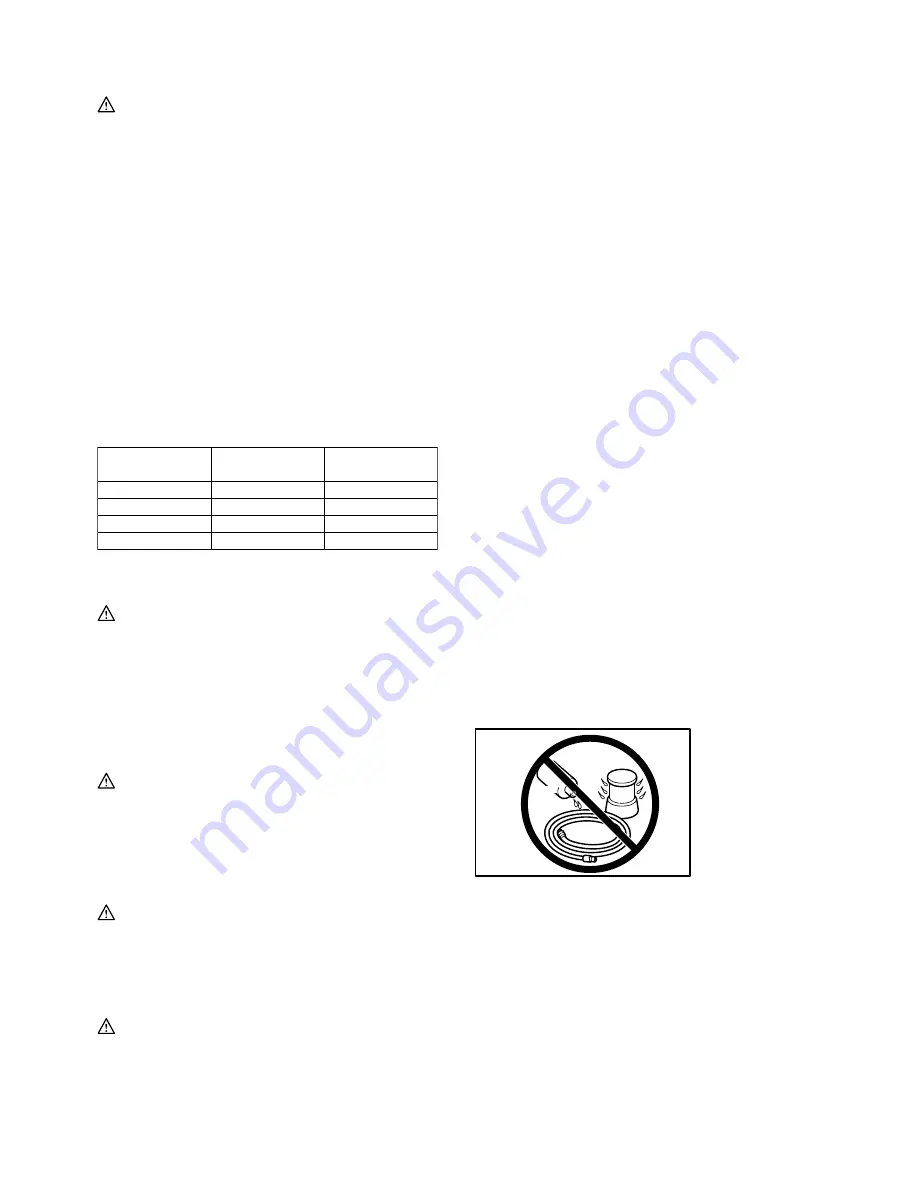

Fig.24

Keep the air hose away from heat (over 60°C, over

140°F), away from chemicals (thinner, strong acids or

alkalis). Also, route the hose away from obstacles which

it may become dangerously caught on during operation.

Hoses must also be directed away from sharp edges

and areas which may lead to damage or abrasion to the

hose.

Stove

Thinner

004320

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized Service Centers,

always using Makita replacement parts.

Summary of Contents for AN610H

Page 62: ...62 ...

Page 63: ...63 ...

Page 64: ...64 Makita Corporation Anjo Aichi Japan 884844B977 ...