2 ENGLISH

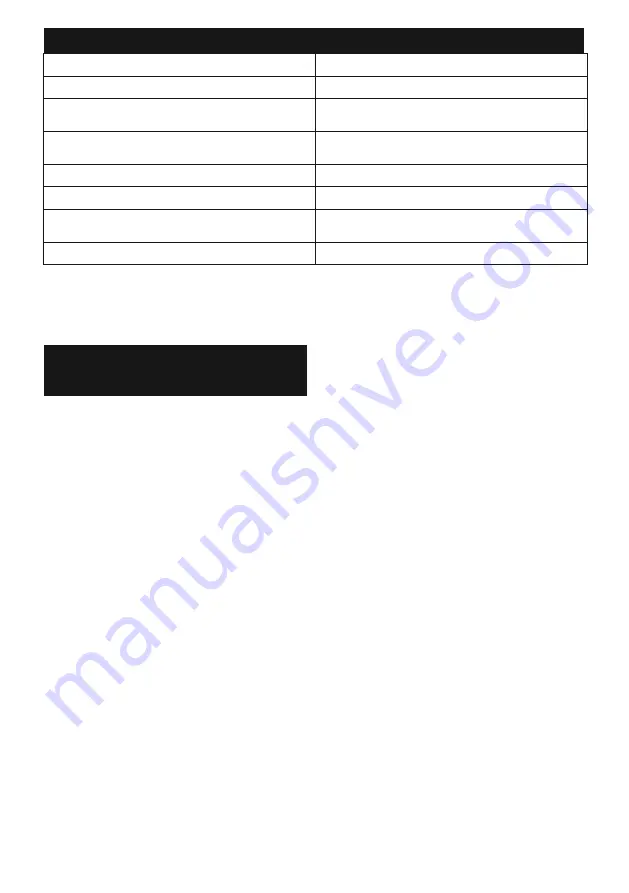

SPECIFICATIONS

Model:

AN613

Air pressure

0.49 - 0.83 MPa (70 - 120 PSIG)

Applicable nails

Wire-

collated coil nails (collation angle 15°)

Sheet-

collated coil nails (collation angle 15°)

Nail length (L) x Shank diameter (D)

L: 38 mm - 65 mm x D: 2.3 mm - 2.5 mm

(L: 1-

1/2″ - 2-1/2″ x D: 0.090″ - 0.099″)

Nail capacity

200 - 300 pcs.

Minimum hose diameter

6.5 mm (1/4″)

Dimensions (L x W x H)

275 mm x 127 mm x 319 mm

(10-

7/8″ x 5″ x 12-1/2″)

Net weight

2.2 kg (4.9 lbs)

•

Due to our continuing program of research and development, the specifications herein are subject to change

without notice.

•

Specifications may differ from country to country.

SAFETY WARNINGS

Important safety instructions

For personal safety and proper operation and

maintenance of the tool, read this instruction

manual carefully before using the tool.

WARNING: WHEN USING THIS TOOL, BASIC

SAFETY PRECAUTIONS SHOULD ALWAYS BE

FOLLOWED TO REDUCE THE RISK OF PERSONAL

INJURY, INCLUDING THE FOLLOWING:

READ ALL INSTRUCTIONS.

Personal Protective Equipment

1.

Always wear safety glasses to avoid eye injury

from dust or fasteners. The safety glasses

should conform with the requirements of ANSI

Z87.1.

WARNING:It is an employer's responsibility to

enforce the use of safety eye protection

equipment by the tool operators and by other

persons in the immediate working area.

2.

Wear hearing protection to protect your ears

against exhaust noise and head protection.

Also wear light but not loose clothing. Sleeves

should be buttoned or rolled up. No necktie

should be worn.

Flammable Atmospheres

1.

Do not operate tool in explosive atmospheres,

such as in the presence of flammable liquids,

gases or combustible dust.

Tool modification

1.

The tool should not be modified unless

authorized in the tool manual or approved in

writing by the tool manufacturer.

Tool maintenance

1.

Refer to the tool maintenance instructions for

detailed information on the proper

maintenance of a tool.

Recommended fasteners and accessories

1.

Use only fasteners made or recommended by

the tool manufacturer, or fasteners that

perform equivalently to those recommended

by the manufacturer.

2.

Use only accessories made or recommended

by the tool manufacturer, or accessories that

perform equivalently to those recommended

by the manufacturer.

Inspect tool before operating to:

1.

Use only power source specified in the

instruction manual.

Operate the tool within the specified air

pressure on the tool label for safety and longer

tool life. Do not exceed the recommended max.

operating pressure. The tool should not be

connected to a source whose pressure

potentially exceeds 1.38 MPa (200 PSIG).

2.

Never use the tool with other than compressed

air. If bottled gas (carbon dioxide, oxygen,

nitrogen, hydrogen, air, etc.) or combustible

gas (hydrogen, propane, acetylene, etc.) is

used as a power source for this tool, the tool

will explode and cause serious injury.

3.

Always check the tool for its overall condition

and loose screws before operation. Tighten as

required.

4.

Make sure all safety systems are in working

order before operation. The tool must not

operate if only the trigger is pulled or if only

the contact element is pressed against the

wood. It must work only when both actions are

performed. Test for possible faulty operation

with fasteners unloaded and the contact

element in fully pulled position.

5.

Always check contact element as instructed in

this manual. Fasteners may be driven