P

2

/

8

R

epair

No need to lubricate.

(1) Disassemble Motor section from Housing set as drawn in

Fig. 1

.

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Fan 88, DC motor and Pulleys

[1] NECESSARY REPAIRING TOOLS

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Code No.

Description

Use for

1R045

Gear extractor (large)

removing/ mounting Spindle from/ to Motor bracket

1R291

Retaining ring S and R pliers

removing/ mounting Retaining ring S-7 from/ to Spindle

781036-5 Wrench 10

removing/ mounting Pulley 7.5-24.1 from/ to DC motor

[2] LUBRICATION

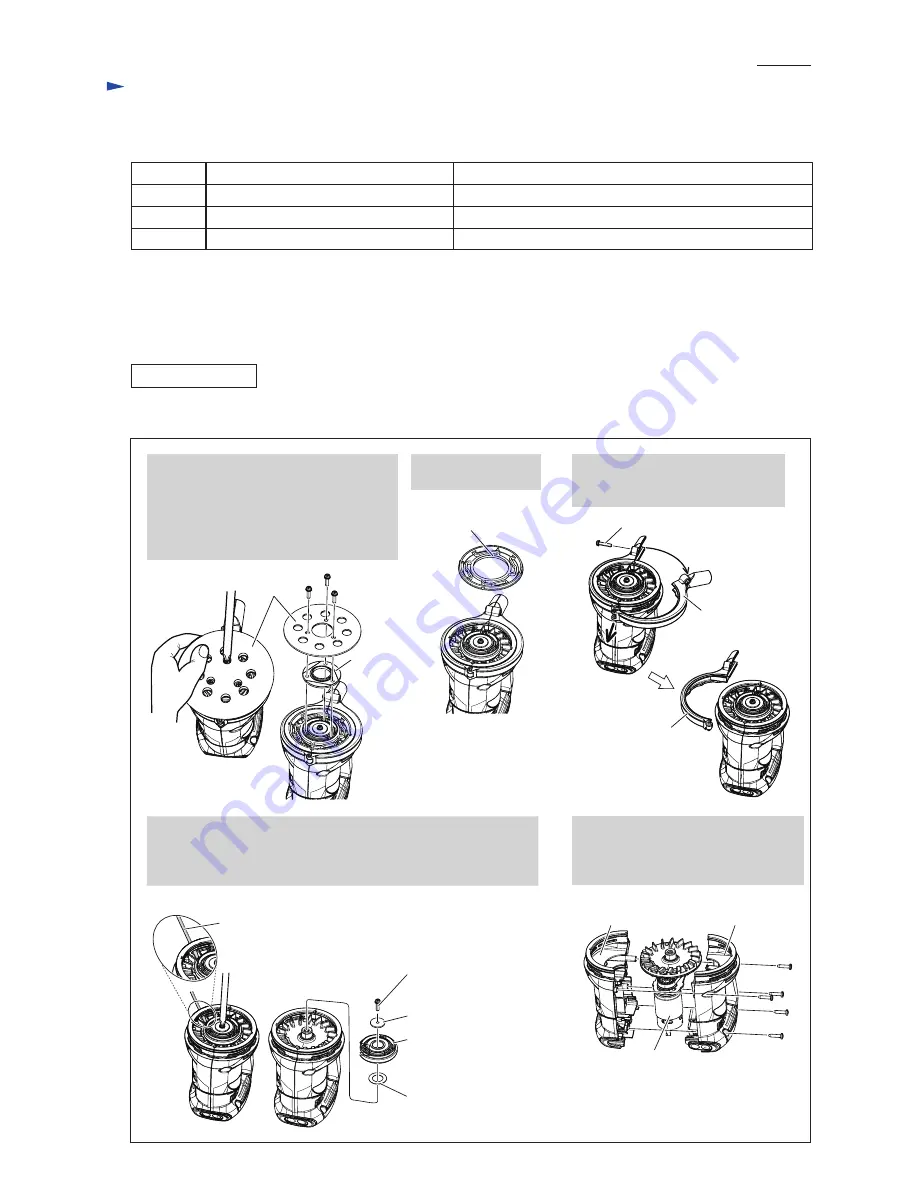

DISASSEMBLING

1. While holding Pad 123 firmly by hand,

unscrew three M4x16 Pan head screws.

Then remove Pad 123 and Bearing box

cover from Housing set.

Note

: Bearing box cover may be removed

together with Pad 123.

2. Remove Brake ring

form Housing set.

3. Unscrew M4x20 Pan head screw

and remove Skirt set (R & L)

from Housing set.

Fig. 1

Pad 123

Bearing

box cover

Skirt R

Skirt L

Brake ring

M4x16 Pan

head screw

Flat washer 4

5. Remove Housing R by unscrewing

five 4x18 Tapping screws.

And then remove Motor section from

Housing L.

Flat washer 15

Bearing box with

Ball bearing

6202DDW

Housing R

Motor section

Housing L

M4x20 Pan head screw

4. While blocking Fan 88 with Slotted screwdriver inserted

through the vent of Housing set, remove M4x16 Pan head screw.

Then remove Flat washer 4, Bearing box with Ball bearing

6202DDW and Flat washer 15 from Housing set.

Slotted screwdriver

as a stopper

4x18 Tapping

screw (5 pcs.)