5

-

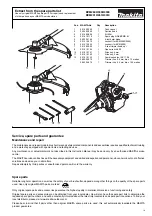

Ensure that no fuel or chain oil oozes into the soil (environmental

protection). Use an appropriate base.

- Refuelling is not allowed in closed rooms. Fuel vapors will

accumulate near the

fl

oor (explosion hazard).

-

Carefully tighten the locking screw of the fuel tank and inspect

the fuel cap at regular intervals.

-

Change the place before starting the engine (at least 3 meters

from the place of refuelling) (6).

- Fuel cannot be stored for an unlimited period of time. Buy

only as much as will be consumed in the near future.

- Use only approved and marked containers for the transport

and storage of fuel. Ensure children have no access to fuel.

Putting into operation

-

Do not work alone. Another person must be nearby in case

of emergencies

(

within shouting distance

).

-

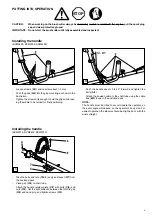

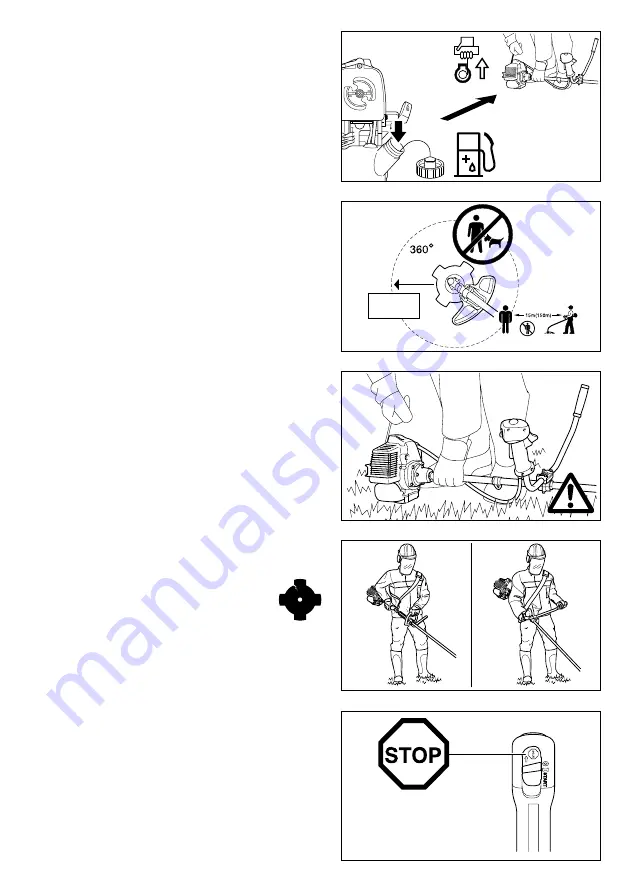

Children and other persons must remain more than 15 meters

(50 feet) from the working area. Keep an eye out for animals

as well (7).

-

Before use always check that the brushcutter is safe for

operation:

Make sure the cutting tool is securely installed. The throttle

must automatically return to the off position when released,

and the throttle lever lock must work properly. The cutting tool

must not turn during idling. The handles should be clean and

dry. The on/off switch must function properly. The guard must

be undamaged and securely installed in the correct position.

Otherwise you are in danger of injury!

- Start the brushcutter only in accordance with the instructions.

Do

not use any other methods for starting the engine

(8)

!

-

Use this brushcutter and its cutting tools only for the uses they

are intended for as speci

fi

ed in the documentation.

-

Start the brushcutter only after complete assembly and

inspection. Operation of the device is only permitted after

all the appropriate accessories are attached!

-

The cutting tool must be equipped with its appropriate

guard. Never run the cutter without this guard!

-

The cutting tool must not turn during idling. If necessary adjust

the idling speed.

-

Before starting, make sure that the cutting tool has no contact

with hard objects such as branches, stones etc.

- The engine must be switched off immediately if there are any

noticeable changes in the behavior of the equipment.

- Should the cutting tool hit stones or other hard objects, im-

mediately switch off the engine and inspect the cutting tool.

- Inspect the cutting tool at frequent intervals for damage (de-

tect hairline cracks by means of tapping - noise test). Hairline

cracks can occur in the region of the base of the

teeth after long use.

Damaged cutting tools and

cutting tools with hairline cracks must not be

used any longer under any circumstances.

-

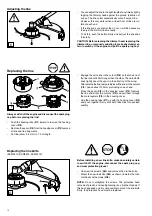

Operate the brushcutter only with the shoulder strap

attached, which is to be suitably adjusted before putting the

brushcutter into operation. It is essential to adjust the shoulder

strap according to the user’s size to prevent fatigue during use.

Never hold the cutter with one hand during use.

- When working with the brushcutter always hold it with both

hands (9).

Keep proper footing and balance at all times.

-

Operate the brushcutter in such a manner as to avoid inhalation

of the exhaust gases. Do not start or operate the brush cutter

in closed rooms (risk of gas poisoning). Carbon monoxide is

an odorless gas. Work only in well-ventilated places.

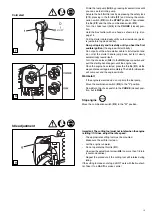

- When taking a break or leaving the brushcutter unattended,

turn off the engine (10) and set the brushcutter down in such

a way that there is no risk of injury to yourself or others.

-

Never put the hot brushcutter onto dry grass or onto any com-

bustible materials.

- Shut off the engine during transport or when moving on to a

new location (10).

- Never operate the engine with a faulty exhaust muf

fl

er.

3 meters

(10 feet)

Schematic

drawing

●

Breaks

●

Transport

●

Refuelling

●

Maintenance

●

Tool Replacement

7

8

9

10

6

15 meters

(50 feet)

BCM2310

BCM2610

BCM3310

BCM2600

BCM3300

BCM4300