7

Storage

- The brushcutter must be safely stored in a dry room. Use the

tool protection for metal cutting tools. Keep the brushcutter out

of reach of children.

-

If the brushcutter is stored for a long period of time, it should be

given a thorough maintenance check and a complete inspection

at an authorized MAKITA service centre.

- If the brushcutter is stored for a long period of time, the fuel

tank should be completely emptied and the carburetor run dry.

Fuels may only be stored for a limited period of time and could

cause deposits to form in the tank or in the carburetor.

- Fuel remains in reserve canisters should be used for other

engines or disposed of.

Maintenance

- Always make sure the brushcutter is in good working order

before using it. This includes in particular the cutting tool,

guard, harness and fuel system (check for leaks). Particular

attention must be paid to the cutting blades, which must be

correctly sharpened.

CAUTION

:

Metal cutting tools must be sharpened only at an

authorized service centre!

A tool which has been improperly sharpened can cause

unbalance and thus considerable danger of injury. Apart from

this, the equipment may be damaged due to vibrations.

- When changing the cutting tool, cleaning the brushcutter and

the cutting tool etc.,

it is essential to switch off the engine

and pull the spark plug cap

.

- Replace cracked, bent, warped, damaged or dull cutting

tools immediately. Never straighten or weld damaged cutting

tools.

-

Operate the brushcutter with as little noise and pollution as pos-

sible. In particular check the correct setting of the carburetor.

- Clean the brushcutter at regular intervals and check that all

screws and nuts are well tightened.

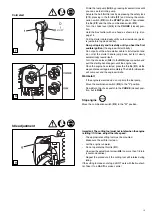

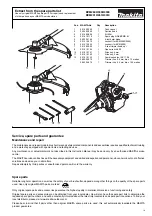

- Never service or store the brushcutter near open

fl

ames (16)!

-

Always store the brushcutter in a locked storage area, with the

fuel tank completely empty and the carburetor run dry.

Observe the accident prevention instructions issued by the

relevant trade associations and insurance companies. Do not

make any modi

fi

cations to the brushcutter - you will only be

putting your own safety at risk!

The performance of maintenance or repair work by the user is

limited to those activities described in this instruction manual. All

other work must be done by the MAKITA customer service (17).

Use only original MAKITA spares and accessories.

The use of non-MAKITA spares, accessories, or cutting tools in-

creases the risk of accident. MAKITA will not accept any liability for

accidents or damage caused by the use of non-approved cutting

tools and

fi

xing devices of cutting tools, or accessories.

First Aid

A

fi

rst-aid kit should always be nearby as a precaution in the

event of an accident.

Immediately replace any items taken from the

fi

rst aid kit.

When calling for help, give the following information:

Place of accident, what happened, number of persons injured,

nature of injuries, your name.

NOTE

Individuals with poor circulation who are exposed to excessive

vibration may experience injury to blood vessels or the nervous

system. Vibration may cause the following symptoms to occur in

the

fi

ngers, hands or wrists: ”Falling asleep” (numbness), tingling,

pain, stabbing sensation, alteration of skin colour or of the skin.

If

any of these symptoms occur, see a physician!

18

16

19

17

SERVICE