1

Daily maintenance

The following maintenance work must be carried out each time

after the brushcutter has been used.

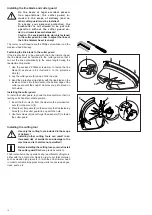

Cleaning the air filter

If the workplace is very dusty or sandy, the

filter must be cleaned at regular intervals, due

to the fact that only a clean air filter will gua-

rantee full engine performance. Coarse parti-

cles of dirt can destroy the engine!

Renew damaged air filters immediately!

To clean the air filter, lay down the brushcutter so that it is resting

on its foot in stable position.

The tool you will require is the Phillips screwdriver.

1 Unscrew the screw (

1

).

2 Grab the air filter cover (

2

) at the bottom and pull it off.

3 Push the choke lever (

3

) all the way up to the limit stop.

Particles of dust can no longer drop into the carburetor

now.

4 Remove both air filters (

4

,

5

) and wash them off in lukewarm

alkaline soap solution with commercial-grade dish-washing

detergent.

5 Let the air filters dry completely.

6 Reinsert both air filters (first the white one (

5

) with the clip

facing downward on the left-hand side).

7 Place the air filter cover on the upper clips (

6

) first, and

then press the lower part of the cover in the direction of

the engine (you must be able to hear the cover snap into

place).

8 Retighten the screw firmly.

Weekly maintenance

The following maintenance work must be carried out once a

week during regular use.

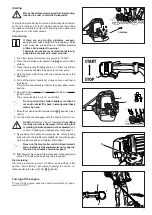

Checking/replacing the spark plug

The engine must have cooled down completely before you can

begin to the check or replace the spark plugs.

Lay down the brushcutter first so that it is resting on its foot in

stable position.

The tools you will require is the combination wrench (plus the

screwdriver as a handle) as well as a pair of insulated pliers.

Materials: Use NGK-CMR 6A-type spark plugs only

(see extract from the spare parts list).

1 Turn out the screw (

1

).

Remove the spark plug cap (

2

).

3 Pull off the spark plug connector (

3

) from the spark plug.

4 Use the combination wrench to turn the spark plug (

4

) out

of the opening.

The spark plug must be replaced if its insulation

body is damaged or if its electrode is extremely

burned, soiled or oiled up, or if you can no lon-

ger see a spark during the spark test described

below.

The gap between the electrodes must be

0.7-0.8 mm

(see illustration)

.

0,7–0,8 mm

4

2

1

3

5

6

4

2

1

3