If you want to check the igniting spark (otherwise continue with

step 10):

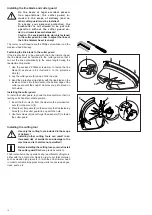

5 Plug the spark plug connector onto the unscrewed spark

plug.

6 Use the combination wrench to make ground contact to the

cylinder.

7 Use a pair of insulated pliers to press the spark plug con-

nector with the spark plug lightly against the combination

wrench but as far away as possible from the spark plug

hole.

8 Push the short-circuit switch (

5

) to "START".

9 Pull the starter cable forcefully.

If the spark plug is functioning perfectly, you must be able

to see a spark on the electrodes.

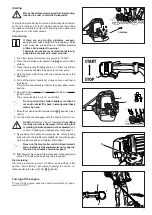

10 If necessary, use the combination wrench to screw in a new

spark plug.

11 Put the spark plug cap back on and fasten it with the

screw.

Maintenance after 50 hours of operation

The following maintenance work must be carried out after 50

hours of operation.

Lubricating the flexible shaft with grease

Do not lubricate the flexible shaft with grease

on your own. The shaft must be lubricated with

grease in one of the many MAKITA service cen-

ters!

Lubricating the angular gearbox with grease

Do not lubricate the angular gearbox with grease

on your own. The angular gearbox must be lu-

bricated with grease in one of the many MAKITA

service centers!

The lubrication can be precisely dosed in a workshop. This

ensures that excessive amounts of grease do not cause over-

heating in the angular gearbox.

Changing the engine oil

Following first-time operation of the brushcutter,

the engine oil must be changed after 20 hours

of operation and then after every 50 hours of

operation.

Prevent contact of the skin with mineral oil

products. Wear gloves when changing the oil.

Change and clean your protective clothing more

frequently.

Mineral oil products, including oils, degrease

the skin. In case of repeated, longer contact, the

skin will dry up. This can result in various skin

diseases. Beyond that, allergic reactions are well

known.

Contact of the eyes with oil results in irritations. In

case of eye contact, wash the affected eye immediate-

ly with clear water. If the irritation does not subside, a

physician must be consulted immediately!

Make sure that oil does not get into the ground. Use a sui-

table base surface. Wipe up unintentionally spilt oil or bind

it with suitable binding agents! Dispose of old oil properly

according to environmental regulations!

5