BFL060F

Cordless Angle Screwdriver 9.6V

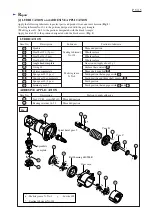

Model No.

Description

PRODUCT

T

ECHNICAL INFORMATION

C

ONCEPT AND MAIN APPLICATIONS

S

pecification

S

tandard equipment

O

ptional accessories

P 1/15

W

H

L

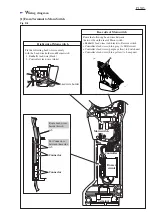

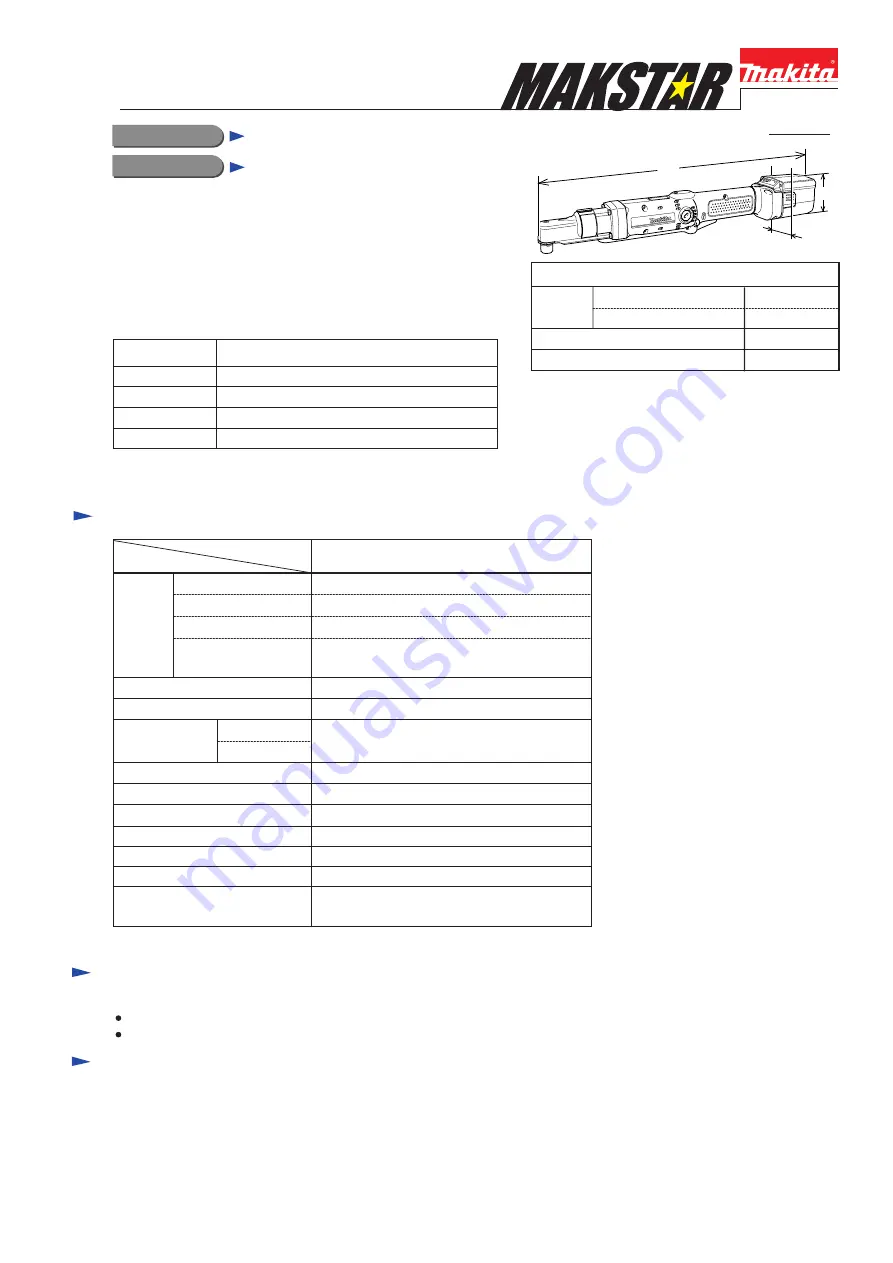

Dimensions: mm (")

Width (W)

Height (H)

Length

(L)

w/ BH 9033, BH9033A

w/ BH 9020, BH9020A

430 (17)

454 (17-7/8)

74 (2-15/16)

65 (2-9/16)

Model BFL060F has been developed as a sister tool of

Model BFL080F, featuring fastening torque lower than BFL080F.

This product is available in the following variations.

Model No.

Driving shank

BFL060F2Z

6.35mm (1/4") Hex socket for C-form Bit

BFL060F1Z

6.35mm (1/4") Hex socket for E-form Bit

BFL060FZ

9.5mm (3/8") Square drive

BFL060F5Z

6.35mm (1/4") Square drive

BFL060F

Model

Specifications

No load speed: rpm= min

-1

450

15/ 22

with DC18RA

150

1.5*

1

/ 1.7*

2

(3.3*

1

/ 3.7*

2

)

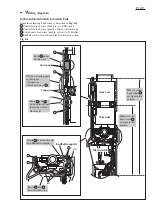

Battery

Driving shank: mm (")

Net weight: kg (lbs)

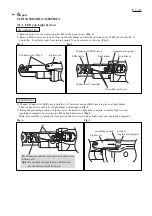

LED Job light

Torque adjustment

Torque range:

N.m (in.lbs)

1.5 - 6

(13 - 53)

Hard joint

Soft joint

Yes

Yes

See the list above.

Electric brake

Soft start

Yes

Reverse switch

Yes

Yes

Cell

Charging time: min.

Voltage: V

Capacity: Ah

Ni-MH

9.6

2.0/ 3.3

Max output: W

*1 with 2.0Ah battery BH1220C, *2 with 3.3Ah battery BH1233C

No, but the following item(s) will be supplied with the machine if required:

Torque adjust tool

Protector

Battery BH9020

Battery BH9020A

Battery BH9033

Battery BH9033A

Fast charger DC18RA

Charger DC24SA

(for North America only)

Charger DC24SC

(for all countries except North America)

Auto refresh adapter ADP03

Protectors (red/ blue/ yellow/ clear)

Torque adjust tool

Angle head set

Note: The following items are not supplied with the machine:

Charger, Battery, Plastic carrying case