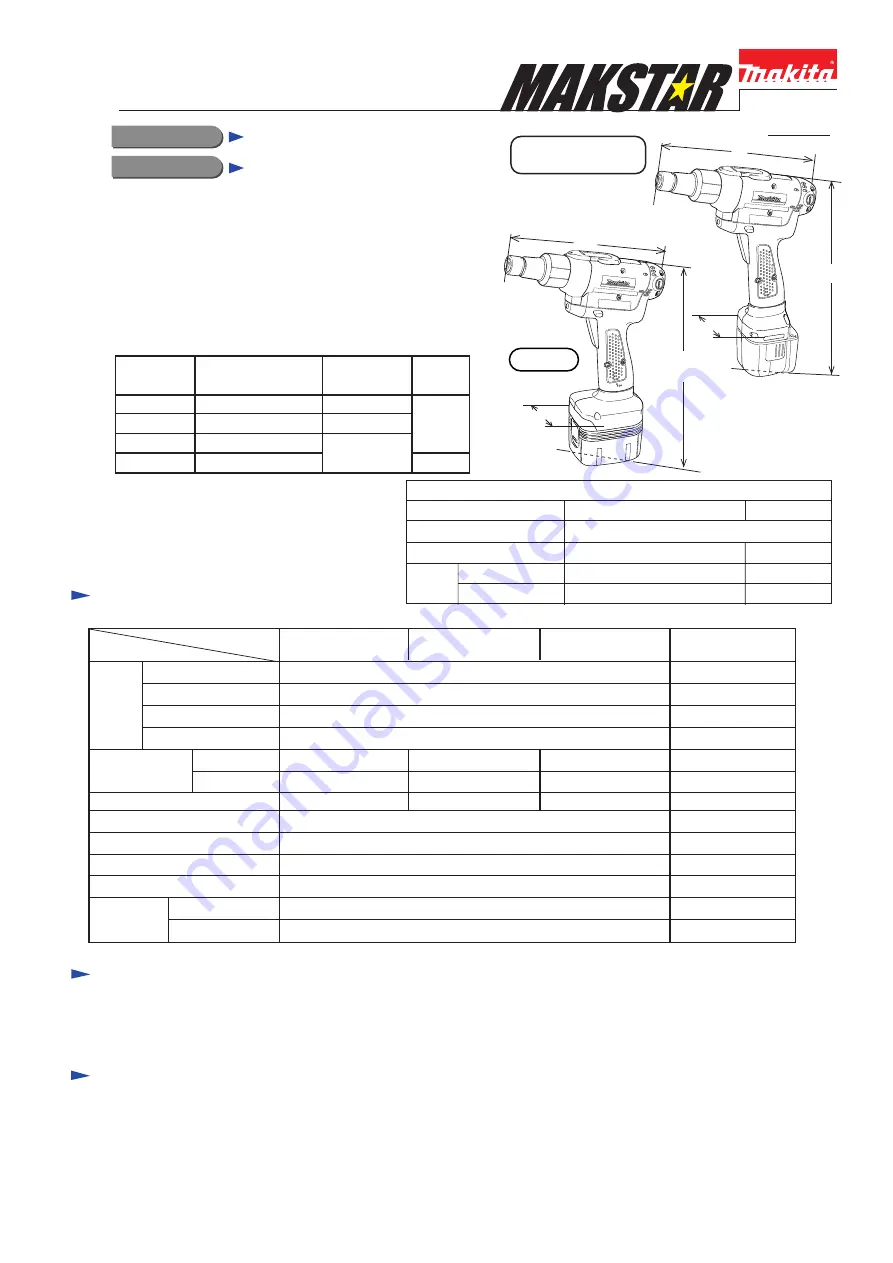

Models No.

Description

PRODUCT

C

ONCEPTION AND MAIN APPLICATIONS

S

pecification

S

tandard equipment

O

ptional accessories

< Note > The standard equipment for the tool shown may differ from country to country.

P 1 / 15

T

ECHNICAL INFORMATION

L

H

W

BFT040F, BFT080F,

BFT122F

* Adjust grip for torque adjusting ......... 1 pc. (exclusively for Italy, USA, Canada)

* Protector ............................................. 1 pc. (exclusively for Germany)

For BFT040F, BFT080F and BFT122F

* Battery BH9020

* Battery BH9020A

* Battery BH9033

* Battery BH9033A

* Charger DC14SA

* Charger DC24SA

* Auto refresh adapter ADP03

* Protectors ( red, blue, yellow and clear )

* Adjust grip for torque adjusting

BFT040F, BFT080F, BFT122F,

BFT123F

Cordless Screwdrivers 9.6V

12V

L

H

W

BFT123F

Dimensions : mm ( " )

Width ( W )

Height

( H )

Length ( L )

Model No.

BFT040F, BFT080F, BFT122F

BFT123F

200 (7-7/8)

260 (10-1/4)

283 (11-1/8)

251 (9-7/8)

274 (10-3/4)

65 (2-9/16)

71 (2-13/16)

w/2.0Ah battery

w/3.3Ah battery

Specially developed for fastening works in assembling line.

Their common feature and benefits are as follows.

* New charging system

* Higher accuracy in fastening torque

* Superior handling

BHT123F (12V) is applicable to tightening at

high turning angle.

And their fastening torque range is as listed below.

Voltage

(V)

Model No.

BFT040F

BFT080F

BFT122F

BFT123F

Torque range in

hard joint : (N.m)

1 - 4

3 - 8

5 - 12

5 - 12

9.6

12

Identification

plate

Yellow

Blue

Red

BFT040F

BFT080F

Ni-MH

Ni-MH

BFT122F

BFT123F

Model No.

Specifications

No load speed : rpm.= min

-1

9.6

2.0 / 3.3

950

540

320

390

19.2 / 31.7

1.3 (2.9)

1.5 (3.3)

1.6 (3.5)

1.8 (4.0)

2.0 / 3.3

24.0 / 39.6

12

Battery

Soft joint

Hard joint

Driving shank : mm ( " )

Externally accessible brush

Net weight

: kg(lbs)

LED Job Light

Soft start

Type of cell

Voltage : V

Capacity : Ah

Energy : Wh

Torque range

: N.m (in.lbs)

w/ 2.0Ah battery

w/ 3.3Ah battery

1 - 4 (8.85 - 35.4)

3 - 8 (26.6 - 70.8)

5 - 12 (44.3 - 106)

5 - 12 (44.3 - 106)

5 - 12 (44.3 - 106)

1 - 3.5 (8.85 - 31.0)

3 - 6.5 (26.6 - 57.5)

5 - 10 (44.3 - 88.5)

Yes

Yes

Yes

Yes

Yes

Yes

Hex 6.35 (1/4)

Hex 6.35 (1/4)

For BFT123F

* Battery BH1220

* Battery BH1233

* Grip base set

* Grip 37