R

epair

P 3 / 15

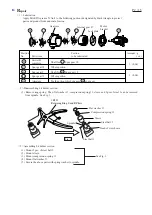

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

< 4 > Disassembling spindle (as a bit holder) and clutch case

( 1 ) After removing bit holder section, remove ring 38 by unscrewing pan head screw M4x4, and clutch case cover

by unscrewing pan head screw M4x8. And then, remove compression spring 2 and switch lever. See Fig. 2.

( 2 ) Remove clutch case by unscrewing 4 pcs. of pan head screw M4x22. See Fig. 3.

( 3 ) Remove retaining ring R-21 from clutch case. And then, knock the edge of clutch case with plastic hammer.

So, spindle (as a bit holder) can be removed from clutch case. See Fig. 4.

( 4 ) Remove ring spring 11 from spindle. And then remove ball bearing 6801LLB on the ring spring 11 side.

See Fig. 5.

( 5 ) After removing ring 12, remove the another ball bearing 6801lLB. See Fig. 6.

Pan head screw M4x8

(black)

Clutch case cover

Clutch case

Compression

spring 2

Clutch case

Clutch section

Switch lever

Pan head

screw M4x22

Compression

spring 5

No.1R311

Retaining Ring Pliers

with Long Bent Nails

Retaining ring R-21

Spindle

Ring 12

Ball bearing

6801LLB

Ring spring 11

1R269

Bearing Extractor

Ball bearing 6801lLB

Ball bearing 6801lLB

Ring 12

Spindle

1R004

Retaining ring S plier

Pan head

screw M4x4 (silver)

Ring 38

< Note > Compression spring 5 can easily fall off clutch section. Be careful, not to lose compression spring 5

in this step.