R

epair

P 5 / 15

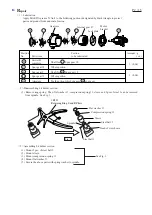

Fig. 14

Fig. 15

Fig. 16

Fig. 17

Fig. 18

Fig. 19

< 6 > Disassembling clutch section

( 8 ) Mount compression spring 2 and switch lever. And secure clutch case cover with pan head screw M4x8.

See Fig. 14.

( 9 ) Secure ring 38 to clutch case with pan head screw M4x4 (silver). See Fig. 15.

Pan head

screw M4x8 (black)

Clutch case cover

Clutch case

Compression spring 2

Switch lever

Pan head

screw M4x4 (silver)

Ring 38

( 1 ) Remove ring 38 and clutch case cover referring to "< 4 > Disassembling spindle (as a bit holder) and clutch case".

( 2 ) Remove clutch section from motor housing. See Fig. 16.

Clutch section

Compression

spring 5

( 4 ) Remove adjust ring complete, compression spring 19

from spindle. See Fig.19.

( 3 ) Insert adjust grip into the hole of adjust ring complete.

Turn adjust grip anti-clockwise, until adjust ring complete

is free from the compression spring 19. See Fig. 17.

Then, lock nut M12 can be separated from adjust ring complete

by turning clockwise with your hand. See Fig. 18.

Lock nut M12

Lock nut M12

Adjust ring

complete

Compression

spring 5

Adjust grip

(Standard equipment

for some countries)

Adjust ring

complete

Compression

spring 19A

Spindle