P 8 /14

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Impact Bolt Section (cont.)

DISASSEMBLING

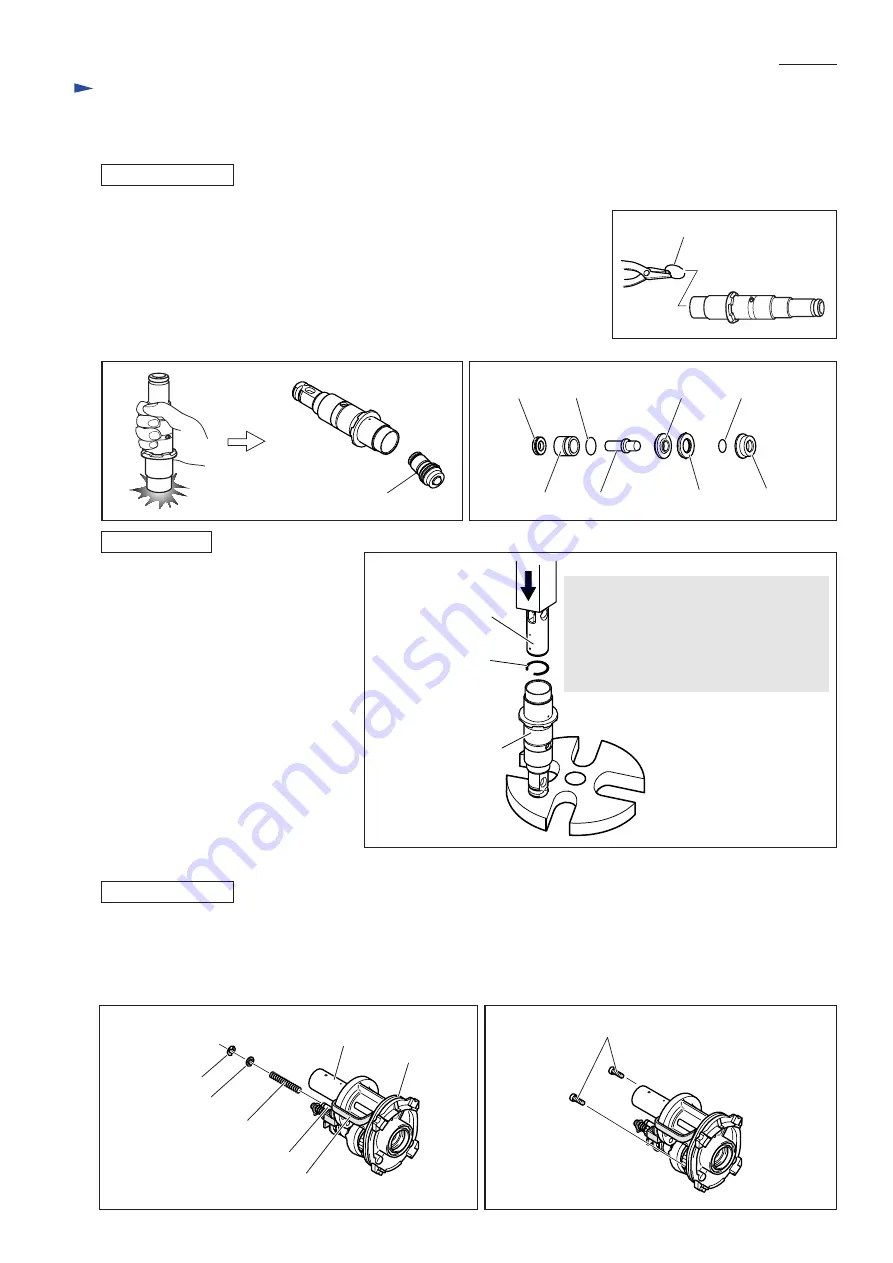

ASSEMBLING

Do the reverse of the disassembling steps.

Note:

When assembling Ring spring 28 to

Tool holder complete;

*Be careful not to position the end of the

spring in either of the side holes on Tool

holder complete.

*Use Piston cylinder as a jig as illustrated

in Fig. 23.

Fig. 21

Fig. 22

5) Ring spring 28 can be pulled off from Tool holder complete when completely

removed from the groove (Fig. 20).

Note: Ring spring 28 will be damaged or deformed in the steps 4) and 5).

Be sure to replace damaged/deformed Ring spring 28 when

assembling Tool holder section.

6) Remove Impact bolt section from Tool holder complete by striking Tool holder

complete against workbench (Fig. 21).

7) Disassemble Impact bolt section as illustrated in Fig. 22.

[3] -6. Swash Bearing Section

DISASSEMBLING

Impact bolt section

X ring 9 O ring 16

Ring 10

O ring 9

Sleeve 9 Impact bolt

Cushion ring 13 O ring case

Fig. 23

Piston cylinder as

an assembling jig

Note:

Never use the Piston cylinder built-in the

machine as the jig because it is scratched

when inserted in Tool holder complete.

Be sure to have an extra Piston cylinder

as a jig for the application.

Ring spring 28

Tool holder complete

1) Remove Inner housing from Gear housing (Fig. 14 in page 6). If Ball bearing 606ZZ remains fixed in Gear housing,

See page 9 for removal. Remove Inner housing from Tool holder section (Fig. 15 in page 6).

2) Remove Stop ring E-4, Flat washer 5 and Compression spring 6 from the pin of Inner housing (Fig. 24).

3) Remove two M4x12 Hex socket head bolts that fasten Bearing retainer to Inner housing (Fig. 25).

Fig. 24

Fig. 25

Inner housing

Ring spring 28

Fig. 20

Fat washer 5

Compression spring 6

Stop ring E-4

Pin of Inner housing

Piston cylinder

Change plate

Hex socket head bolts M4x12