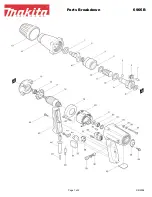

Models No.

Description

PRODUCT

T

ECHNICAL INFORMATION

P 1/

9

BTD141

Cordless Impact Driver

C

ONCEPT AND MAIN APPLICATIONS

S

pecification

S

tandard equipment

O

ptional accessories

Note:

The standard equipment for the tool shown above may differ by country.

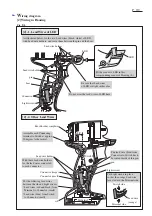

Model BTD141 has been developed as a successor model of BTD140.

Additionally to the same advantages as BTD140, Model BTD141 features:

1.5Ah Li-ion battery BL1815 can be used.

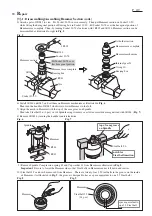

One-touch bit installation

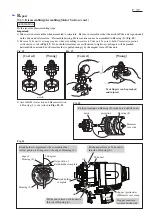

Compact hammer case cover

Phosphorescent bumper that glows blue in dark places

See the product variation list above.

Battery

No load speed: min.-

1

=rpm

Impacts per min.: min.-

1

=ipm

Max. fastening torque

*

: N.m (kgf.cm/ in.lbs)

Charging time: min.

Capacities

Electric brake

Reverse switch

Net weight [with BL1815/ BL1830]: kg (lbs)

Variable speed control by trigger

Capacity: Ah

Cell

Voltage: V

18V

0 - 2,300

0 - 3,200

150 (1,530/ 1,330)

Standard bolt

High tensile bolt

Machine screw

Driving shank

M5 - M14 (3/16 - 9/16")

M5 - M12 (3/16 - 1/2")

Coarse thread screw

22 - 125mm (7/8 - 4-7/8")

M4 - M8 (5/32 - 5/16")

Yes

Yes

Yes

1.3/ 1.5 (2.8/ 3.3)

1.5/ 3.0 (battery BL1815/ BL1830)

Li-ion

220

approx. 15/ 22 with DC18RA

6.35mm (1/4") Hex

This product is available in the following variations.

BTD141RFE

BTD141Z

BTD141ZK

BTD141RFE3

BTD141RFEW

BTD141RHE

BTD141RHEW

BL1830

(Li-ion 3.0Ah)

No

DC18RA

No

Model No.

type

quantity

Charger

No

Yes

Belt

clip

1

2

No

Battery

cover

Yes

No

Plastic

carrying case

2

3

2

2

No

BL1815

(Li-ion 1.5Ah)

Battery

Makita-blue

white

Makita-blue

white

Housing

color

1

1

Phillips bits

Socket bits

Bit piece

Li-ion Battery 1830

Li-ion Battery 1815

Fast charger DC18RA

Charger DC24SA

(for North America only)

Charger DC24SC

(for all countries except North America)

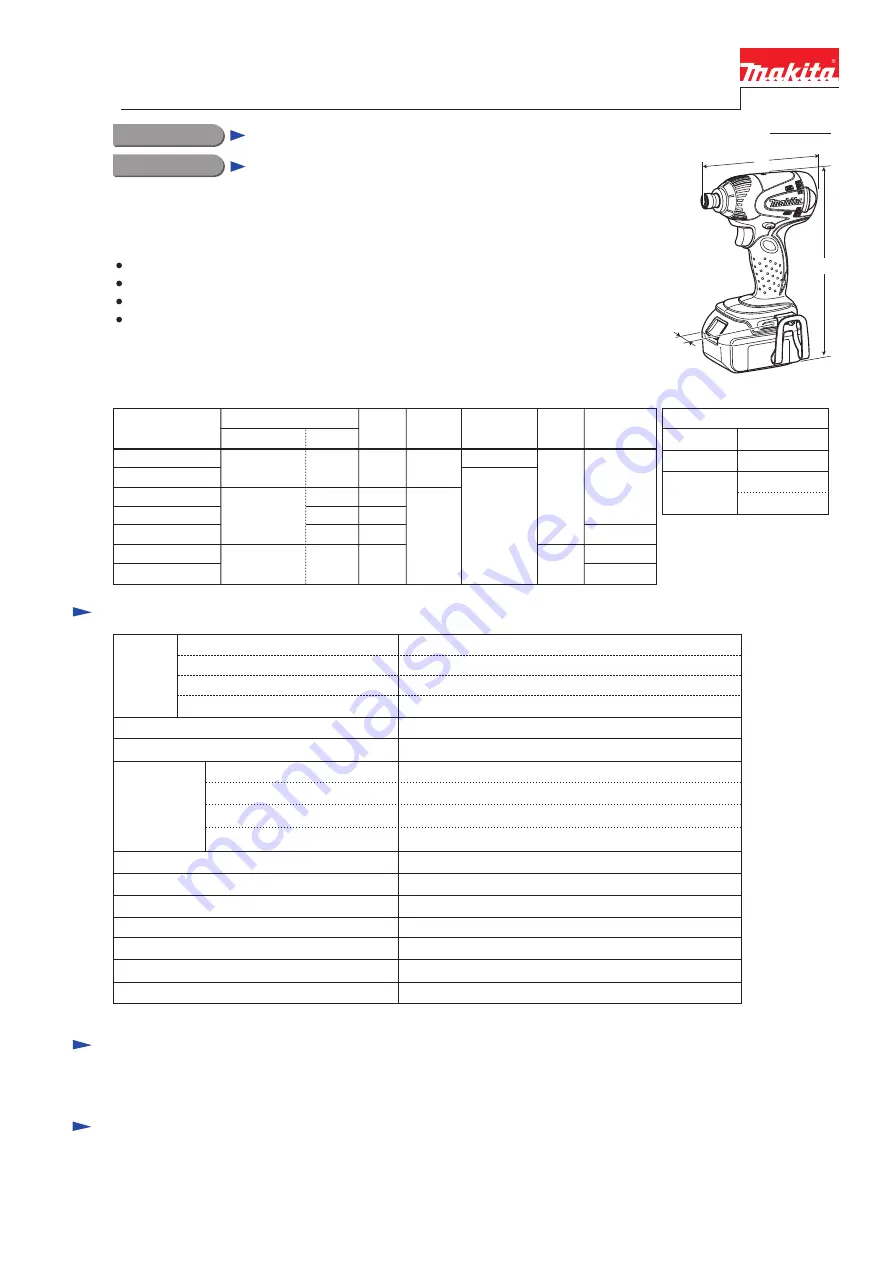

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

145 (5-3/4)

79 (3-1/8)

235 (9-1/4)

*2

217 (8-1/2)

*1

*1: with Battery BL1815

*2: with Battery BL1830

W

L

H

(with Battery BL1830)

Max output (W)

*

C

atalog value (torque at 3 seconds after seating, when fastening M14 high tensile bolt)