6

Installing or removing socket

Fig.6

To install the socket, push it onto the anvil of the tool until

it locks into place.

To remove the socket, simply pull it off.

Hook (Accessory)

CAUTION:

•

When installing the hook, tighten the screw firmly.

Failure to do so may cause the breakage of the tool

or personal injury.

Fig.7

The hook is convenient for temporarily hanging the tool.

This can be installed on either side of the tool.

To install the hook, insert it into a groove in the tool

housing on either side and then secure it with a screw. To

remove, loosen the screw and then take it out.

Adjusting the angle head

The angle head can be adjusted 360°(8 positions in

45-degree increments). To adjust it, loosen the hex bolt

and remove the angle head.

Adjust the angle head to the desired position and reinstall

it so that the teeth on the housing will match up with the

grooves in the angle head. Then tighten the hex bolt to

secure the angle head.

Fig.8

Fig.9

Straight head and ratchet head (Accessory)

Straight heads and ratchet heads are available as

optional accessories for various applications on the job.

Fig.10

Fig.11

OPERATION

CAUTION:

•

Always insert the battery cartridge all the way until it

locks in place. If you can see the red part on the

upper side of the button, it is not locked completely.

Insert it fully until the red part cannot be seen. If not,

it may accidentally fall out of the tool, causing injury

to you or someone around you.

Hold the tool firmly and place the socket over the bolt or

nut. Turn the tool on and fasten for the proper fastening

time.

Fig.12

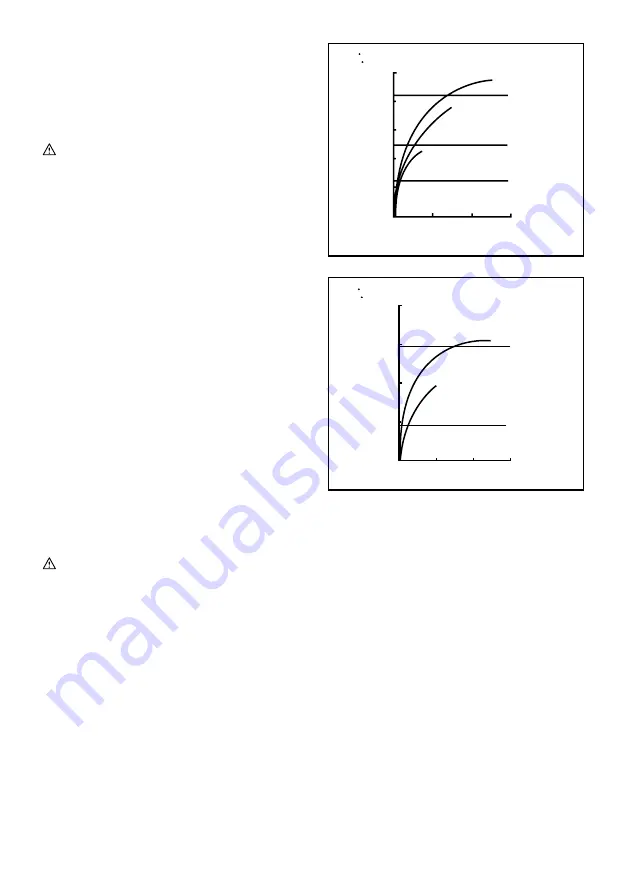

The proper fastening torque may differ depending upon

the kind or size of the bolt, the material of the workpiece

to be fastened, etc. The relation between fastening

torque and fastening time is shown in the figures.

50

40

30

20

10

0

0

1

2

3

M12

(M12)

M10

(M10)

M8

(M8)

(408)

(204)

(510)

(306)

(102)

Standard bolt

N m

Fastening torque

Fastening time

Proper fastening torque

(kgf cm)

(S)

008500

High tensile bolt

N m

Fastening torque

Fastening time

Proper fastening torque

(kgf cm)

(S)

40

30

20

10

0

0

1

2

3

M8

M6

(M8)

(M6)

(408)

(306)

(204)

(102)

008499

NOTE:

•

Hold the tool pointed straight at the bolt or nut.

•

Excessive fastening torque may damage the

bolt/nut or socket. Before starting your job, always

perform a test operation to determine the proper

fastening time for your bolt or nut.

•

If the tool is operated continuously until the battery

cartridge has discharged, allow the tool to rest for

15 minutes before proceeding with a fresh battery

cartridge.

The fastening torque is affected by a wide variety of

factors including the following. After fastening, always

check the torque with a torque wrench.

1.

When the battery cartridge is discharged almost

completely, voltage will drop and the fastening

torque will be reduced.

2. Socket

•

Failure to use the correct size socket will cause

a reduction in the fastening torque.

•

A worn socket (wear on the hex end or square

end) will cause a reduction in the fastening

torque.