P

8

/1

0

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3]-3. Hammer Section

DISASSEMBLING

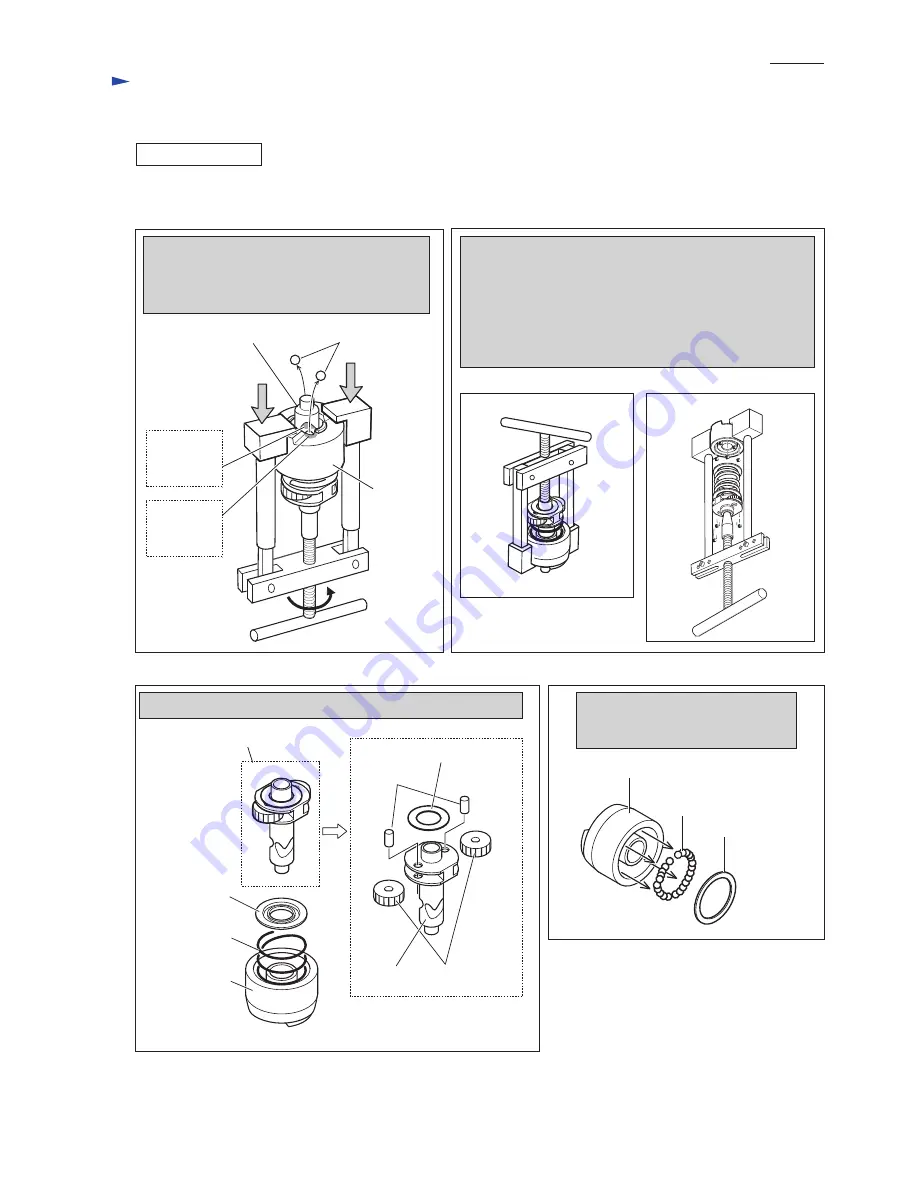

1) Disassemble Hammering section from Hammer case complete. See Figs. 2 to 4.

2) The removed Hammer section are disassembled as illustrated in Figs. 12 to 15.

1. Press down Hammer using 1R045 to align

the opening for Steel ball insertion with

the top of cam grooving on Spindle.

And then remove Steel ball 5.6 from Spindle.

Hammer

Spindle

Top of

cam groove

on Spindle

Opening for

Steel ball

insertion

Steel ball 5.6

(2pcs.)

Fig. 12

2. Hold Hammer section as illustrated in Fig. R,

and release it from the Gear extractor.

Note:

Do not hold gear extractor as illustrated in Fig. F

when releasing Hammer section from the Gear extractor.

Failure to follow this instruction could cause Steel balls

to get out of hammer.

Fig. R

Fig. F

Fig. 13

Compression

spring 25

Cup washer 14

Spindle section

3. Hammer section can now be disassembled as illustrated below.

Hammer

Fig. 14

Hammer

Flat washer 24

Steel ball 3.5

(

24 pcs.

)

4. After removing Flat washer 24,

Steel balls 3.5 can be removed

from Hammer.

Fig. 15

Flat washer 12

Pin 5

Spindle

Spur gear 22