Models No.

Description

NEW TOOL

T

ECHNICAL INFORMATION

C

ONCEPTION AND MAIN APPLICATIONS

S

pecification

S

tandard equipment

O

ptional accessories

< Note > The standard equipment for the tool shown may differ from country to country.

P 1 / 9

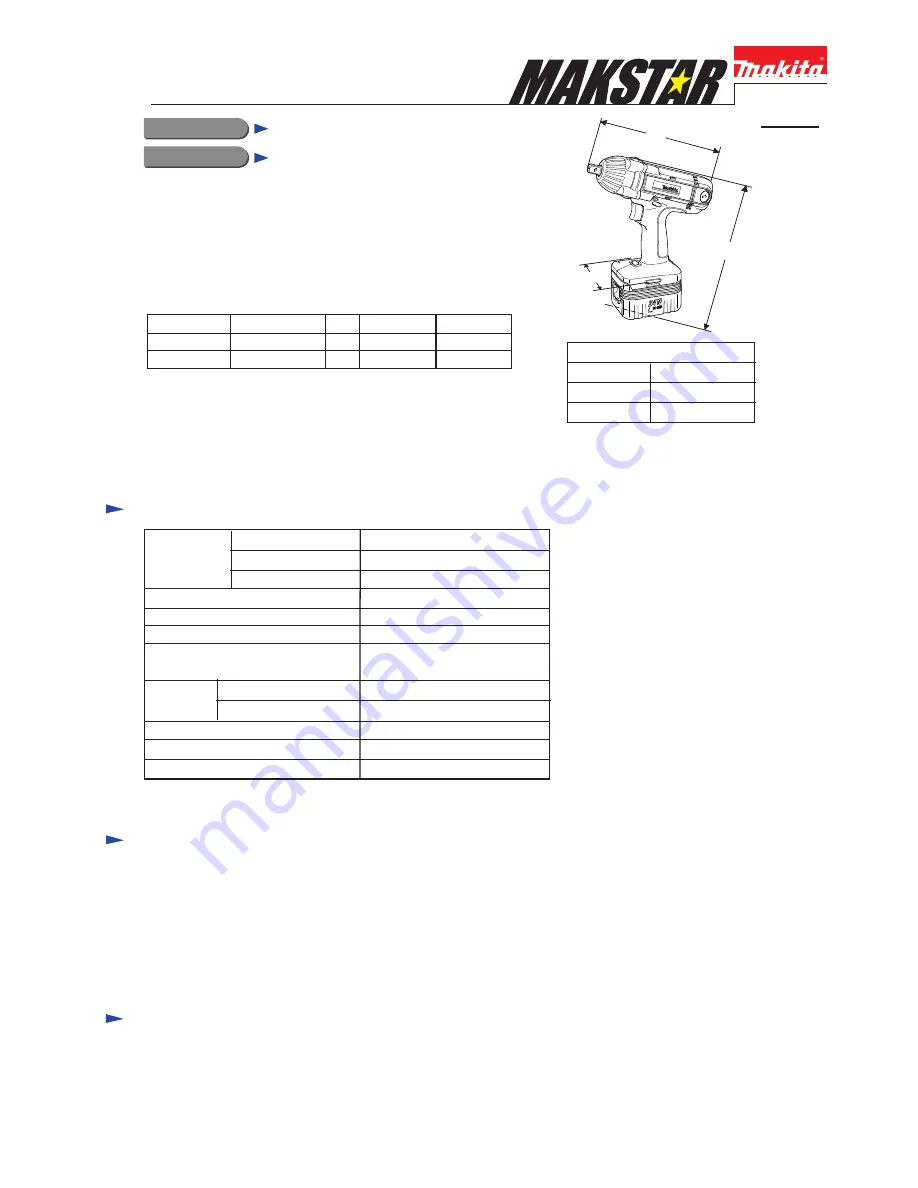

Dimensions : mm ( " )

Width ( W )

Height ( H )

Length ( L )

86 (3-3/8)

277 (10-7/8)

226 (8-7/8)

H

L

W

BTW201

24V Cordless Impact Wrench

The variations of this model are as listed below.

Model No.

Battery

Q'ty Type of cell

Charger

BTW201SH B2417 (1.7Ah) 1pc.

Ni-MH

DC24SA

BTW201SF

B2430 (3.0Ah) 1pc.

Ni-MH

DC24SA

No load speed : (min

-1

= rpm)

Blows per min : (min

-1

= bpm).

Drive shank : mm=( " )

Max. fastening torque

BPM. pre-selection system

Reverse switch

Capacity

Standard bolt

High tensile bolt

200 Nm

(2,040 kgf.cm, 1,770 in.lbs)

0 - 2,000

0 - 3,000

Square 12.7 (1/2)

M10 - M12 (3/8 - 1/2)

M10 - M16 (3/8 - 5/8)

Net weight including battery B2417

2.9Kg (6.3 lbs)

Yes

Yes

Battery

Voltage ( V )

Capacity (Ah)

Type of cell

Ni-MH

3.0

24

* Socket 19-52 ....................... 1 pc.

* Pin 4 ........................ 1 pc.

* O ring 24 ........................ 1 pc. ( Except North American market)

* Various Sockets

* Battery B2417 / 1.7 Ah

* Battery B2430 / 3.0 Ah

* Charger DC24SA

* ADP01 Interchangeable adapter

* ADP02 Refreshing adapter

Model BTW201 can compete with the existing 360W class

AC tool, Mod.6904VH in max. fastening torque.

And its BPM. Pre-selection System prevents the over-tightening.