P 7 / 9

R

epair

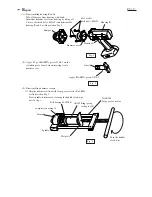

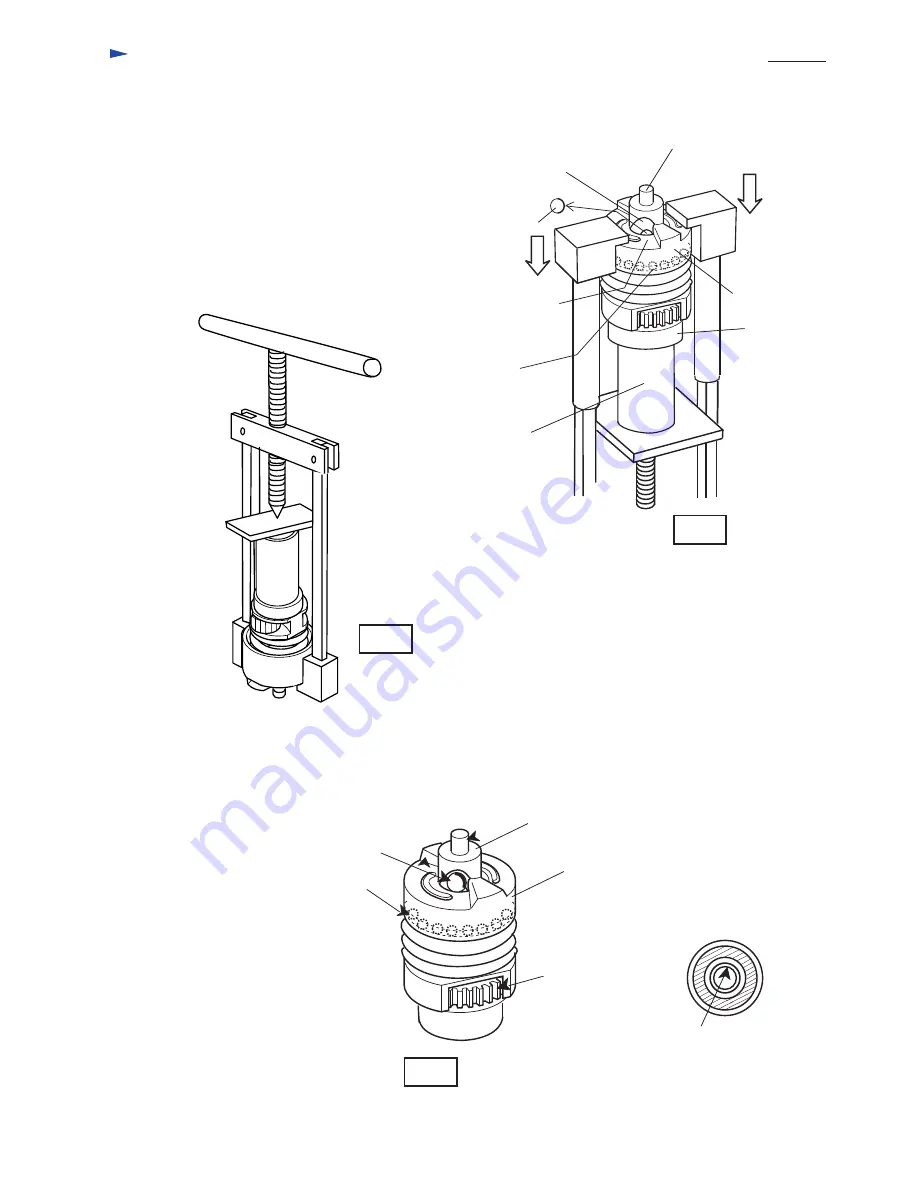

(2)Adjust the opening for steel ball inserting, to the cam groove top of spindle

as illustrated in Fig. 5.

Spindle

Cam groove top

of spindle

Opening for steel

ball inserting

Steel ball 5.6 x 2pcs.

Steel ball 4 x 25pcs.

Hammer

(3)Take off 2 pcs. of steel balls 5.6 with magnetic bar or tweezers from spindle.

(4)Loosen the handle of 1R045 turning it anti-clockwise

and remove hammer from spindle.

(5)When assembling, adjust the "opening for steel ball inserting", to the "cam groove top" of spindle

and insert steel ball 5.6 into hammer as illustrated in Fig. 5.

< Note > Set the hammer as per Fig.5A,

when removing it from spindle.

Otherwise steel balls 4

will fall off hammer.

Ball bearing

6002LLB

1R165 Ring spring

setting tool B

Fig. 5

Fig. 5A

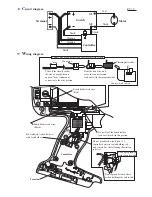

(6) Apply MAKITA grease N No.2 in small volume to the position marked with black triangle mark.

See Fig. 6.

(1) Spindle

(3) Steel ball 5.6 x 2

(2) Steel ball 4 x 25pcs.

Hammer

(4) Spur gear 24

Fig. 6

Bottom view of spindle

Apply MAKITA grease N No.2 in small volume

into the hole of spindle.