13 ENGLISH

Overheat protection

When the tool/battery is overheated, the tool stops

automatically, and the lamp blinks. In this situation, let

the tool cool down before turning the tool on again.

Overdischarge protection

When the battery capacity becomes low, the tool stops

automatically, and the indicator lamp of battery car

-

tridge blinks. If the tool does not operate even when the

switches are operated, remove the batteries from the

tool and charge the batteries.

Protections against other causes

Protection system is also designed for other causes that could

damage the tool and allows the tool to stop automatically.

Take all the following steps to clear the causes, when the tool

has been brought to a temporary halt or stop in operation.

1. Turn the tool off, and then turn it on again to

restart.

2. Charge the battery(ies) or replace it/them with

recharged battery(ies).

3. Let the tool and battery(ies) cool down.

If no improvement can be found by restoring protection

system, then contact your local Makita Service Center.

NOTICE:

If the tool stops due to a cause

not described above, refer to the section for

troubleshooting.

Overload alert

If the tool is operated with excessive load, the overload

indicator will blink in red. In this situation, reduce the

load on the tool. Then, the indicator stops blinking.

►

Fig.4:

1.

Overload indicator

Switch action

WARNING:

Before installing the battery car-

tridge into the tool, always check to see that the

switch trigger actuates properly and returns to

the "OFF" position when released.

WARNING:

NEVER defeat the lock-off button

by taping down or some other means.

A switch with

a negated lock-off button may result in unintentional

operation and serious personal injury.

WARNING:

NEVER use the tool if it runs when

you simply pull the switch trigger without press-

ing the lock-off button.

A switch in need of repair

may result in unintentional operation and serious

personal injury. Return tool to a Makita service center

for proper repairs BEFORE further usage.

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided. To start the tool,

depress the lock-off button and pull the switch trigger.

Release the switch trigger to stop.

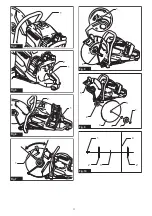

►

Fig.5:

1.

Switch trigger

2.

Lock-off button

NOTICE:

Do not pull the switch trigger hard

without pressing in the lock-off button.

This can

cause switch breakage.

Lighting the lamp

CAUTION:

Do not look in the light or see the

source of light directly.

To turn on the lamp, press the lamp button. To turn off,

press the lamp button again.

►

Fig.6:

1.

Lamp button

2.

Lamp

NOTE:

The lamp will automatically be turned off if

there is no operation with the tool for one minute.

Adjusting the wheel cover

Hold the wheel cover grip and adjust the position of the

wheel cover suitable for your work.

►

Fig.7:

1.

Wheel cover grip

Active feedback sensing technology

The tool electronically detects situations where the

wheel may be at risk to be bound. In the situation, the

tool is automatically shut off to prevent further rotation

of the spindle (it does not prevent kickback).

To restart the tool, switch off the tool first, remove the cause of

sudden drop in the rotation speed, and then turn the tool on.

Electric brake

Electric brake is activated after the tool is switched off.

The brake does not work when the power supply is shut down,

such as the battery is removed accidentally, with the switch still on.

ASSEMBLY

CAUTION:

Always be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

Installing or removing abrasive cut-

off wheel / diamond wheel

CAUTION:

Use only the Makita wrench to

install or remove the wheel.

CAUTION:

When installing the wheel, be sure

to tighten the bolt securely.

CAUTION:

Do not press the shaft lock button

when the wheel is rotating.

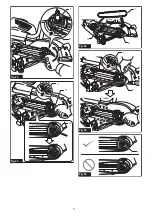

To remove the wheel, press the shaft lock button and

rotate the wheel until the wheel cannot revolve. While

the shaft lock is fully locked, turn the hex bolt counter

-

clockwise using the box wrench. Then remove the hex

bolt, flange, wheel, ring, and flange in order.

►

Fig.8:

1.

Shaft lock button

2.

Box wrench

3.

Tighten

4.

Loosen

►

Fig.9:

1.

Hex bolt

2.

Flange

3.

Ring

4.

Abrasive cut-

off wheel / diamond wheel

5.

Arrow (rotation

direction of the wheel)

To install the wheel, follow the removal procedure in reverse.

BE SURE TO TIGHTEN THE HEX BOLT SECURELY.

Summary of Contents for CE001G

Page 2: ...2 17 1 2 4 3 6 5 16 15 14 12 11 9 13 10 18 7 8 Fig 1 3 1 1 2 Fig 2 1 2 Fig 3 ...

Page 3: ...3 1 Fig 4 1 2 Fig 5 2 1 Fig 6 1 Fig 7 1 2 3 4 Fig 8 3 4 2 5 2 5 1 Fig 9 2 3 4 1 2 Fig 10 ...

Page 4: ...4 1 2 3 Fig 11 1 2 3 Fig 12 1 2 3 Fig 13 Fig 14 1 Fig 15 Fig 16 1 Fig 17 ...

Page 5: ...5 Fig 18 1 2 Fig 19 1 1 Fig 20 1 2 3 Fig 21 ...

Page 6: ...6 1 2 Fig 22 1 2 3 Fig 23 1 2 3 Fig 24 1 2 Fig 25 1 Fig 26 ...

Page 7: ...7 1 Fig 27 1 2 3 Fig 28 ...

Page 106: ...106 ...

Page 107: ...107 ...