9 ENGLISH

Vibration

Work mode: concrete cutting

Left hand

Right hand

Applicable standard

a

h,W

(m/s

2

)

Uncertainty K (m/s

2

)

a

h,W

(m/s

2

)

Uncertainty K (m/s

2

)

2.5

1.5

2.5

1.5

EN60745-2-22

NOTE:

The declared vibration total value(s) has been measured in accordance with a standard test method and

may be used for comparing one tool with another.

NOTE:

The declared vibration total value(s) may also be used in a preliminary assessment of exposure.

WARNING:

The vibration emission during actual use of the power tool can differ from the declared

value(s) depending on the ways in which the tool is used especially what kind of workpiece is processed.

WARNING:

Be sure to identify safety measures to protect the operator that are based on an estimation

of exposure in the actual conditions of use (taking account of all parts of the operating cycle such as the

times when the tool is switched off and when it is running idle in addition to the trigger time).

EC Declaration of Conformity

For European countries only

The EC declaration of conformity is included as Annex A

to this instruction manual.

SAFETY WARNINGS

General power tool safety warnings

WARNING:

Read all safety warnings, instruc-

tions, illustrations and specifications provided

with this power tool.

Failure to follow all instructions

listed below may result in electric shock, fire and/or

serious injury.

Save all warnings and instruc-

tions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Cordless cutter safety warnings

1.

The guard provided with the tool must be

securely attached to the power tool and

positioned for maximum safety, so the least

amount of wheel is exposed towards the oper-

ator. Position yourself and bystanders away

from the plane of the rotating wheel.

The guard

helps to protect operator from broken wheel frag-

ments and accidental contact with wheel.

2.

Use only bonded reinforced or diamond cut-off

wheels for your power tool.

Just because an

accessory can be attached to your power tool, it

does not assure safe operation.

3.

The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool.

Accessories running faster than

their rated speed can break and fly apart.

4.

Wheels must be used only for recommended

applications. For example: do not grind with

the side of cut-off wheel.

Abrasive cut-off wheels

are intended for peripheral grinding, side forces

applied to these wheels may cause them to

shatter.

5.

Always use undamaged wheel flanges that are

of correct diameter for your selected wheel.

Proper wheel flanges support the wheel thus

reducing the possibility of wheel breakage.

6.

Do not use worn down reinforced wheels from

larger power tools.

Wheels intended for a larger

power tool are not suitable for the higher speed of

a smaller tool and may burst.

7.

The outside diameter and the thickness of your

accessory must be within the capacity rating

of your power tool.

Incorrectly sized accessories

cannot be adequately guarded or controlled.

8.

The arbour size of wheels and flanges must

properly fit the spindle of the power tool.

Wheels and flanges with arbour holes that do not

match the mounting hardware of the power tool

will run out of balance, vibrate excessively and

may cause loss of control.

9.

Do not use damaged wheels. Before each

use, inspect the wheels for chips and cracks.

If power tool or wheel is dropped, inspect for

damage or install an undamaged wheel. After

inspecting and installing the wheel, position

yourself and bystanders away from the plane

of the rotating wheel and run the power tool

at maximum no load speed for one minute.

Damaged wheels will normally break apart during

this test time.

10.

Wear personal protective equipment.

Depending on application, use face shield,

safety goggles or safety glasses. As appro-

priate, wear dust mask, hearing protectors,

gloves and shop apron capable of stopping

small abrasive or workpiece fragments.

The

eye protection must be capable of stopping flying

debris generated by various operations. The dust

mask or respirator must be capable of filtrating

particles generated by your operation. Prolonged

exposure to high intensity noise may cause hear

-

ing loss.

Summary of Contents for CE001G

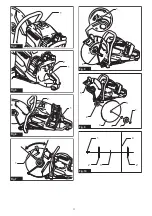

Page 2: ...2 17 1 2 4 3 6 5 16 15 14 12 11 9 13 10 18 7 8 Fig 1 3 1 1 2 Fig 2 1 2 Fig 3 ...

Page 3: ...3 1 Fig 4 1 2 Fig 5 2 1 Fig 6 1 Fig 7 1 2 3 4 Fig 8 3 4 2 5 2 5 1 Fig 9 2 3 4 1 2 Fig 10 ...

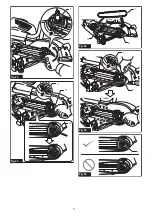

Page 4: ...4 1 2 3 Fig 11 1 2 3 Fig 12 1 2 3 Fig 13 Fig 14 1 Fig 15 Fig 16 1 Fig 17 ...

Page 5: ...5 Fig 18 1 2 Fig 19 1 1 Fig 20 1 2 3 Fig 21 ...

Page 6: ...6 1 2 Fig 22 1 2 3 Fig 23 1 2 3 Fig 24 1 2 Fig 25 1 Fig 26 ...

Page 7: ...7 1 Fig 27 1 2 3 Fig 28 ...

Page 106: ...106 ...

Page 107: ...107 ...