9 ENGLISH

Alert indicator

The indicator lamp on the push drive mode selector

raises an alert with flashing red lights when the tool

works in the following operating conditions.

►

Fig.2:

1.

Indicator lamp

Lamp status

Causes

Remedies

Fast flashing (approx.

one-third second

intervals)

Battery

getting low

Charge the battery

at your earliest

opportunity.

Delayed flashing

(approx. a second

intervals)

Overheated

Let the tool cool

down before turning

it on again.

NOTE:

An over-discharge alert may appear depend

-

ing on the battery status and operational conditions.

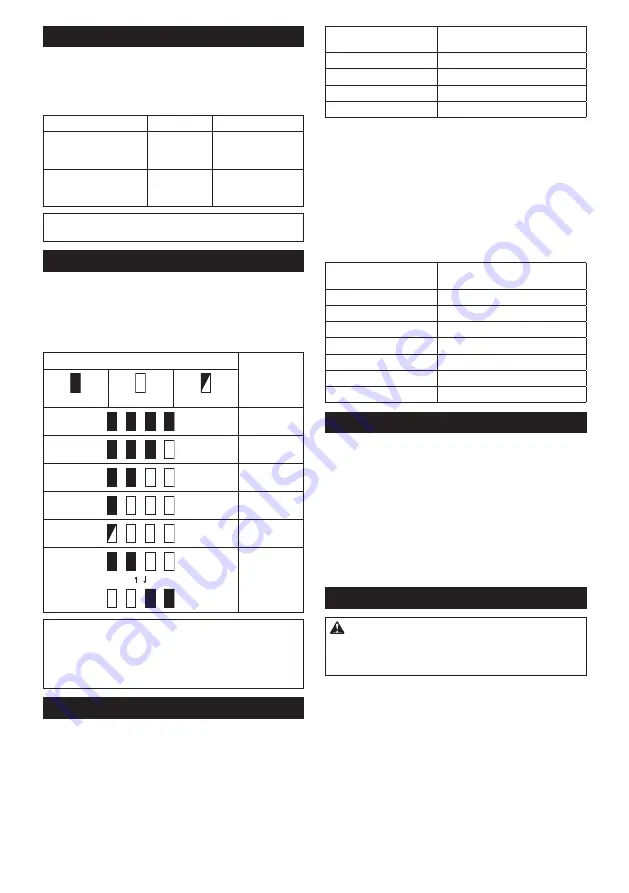

Indicating the remaining battery capacity

Only for battery cartridges with the indicator

►

Fig.3:

1.

Indicator lamps

2.

Check button

Press the check button on the battery cartridge to indi

-

cate the remaining battery capacity. The indicator lamps

light up for a few seconds.

Indicator lamps

Remaining

capacity

Lighted

Off

Blinking

75% to 100%

50% to 75%

25% to 50%

0% to 25%

Charge the

battery.

The battery

may have

malfunctioned.

NOTE:

Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

NOTE:

The first (far left) indicator lamp will blink when

the battery protection system works.

Setting for desired screw lengths

For model DFR452

The tool provides 4 positive-lock screw length settings.

Slide the stopper base out and in while depressing the

levers on the top surface of the stopper base so the

number for desired screw length (indicated on the label)

appears in the reading window. See the following table

for details on the numbers allocated to your desired

screw lengths.

►

Fig.4:

1.

Stopper base

2.

Levers

3.

Label

4.

Reading window

Numbers indicated on

the label

Screw length ranges

20

20 mm (3/4″)

25

25 mm - 28 mm (1″ - 1-1/8″)

32

28 mm - 35 mm (1-1/8″ - 1-3/8″)

41

35 mm - 41 mm (1-3/8″ - 1-5/8″)

For model DFR551

The tool provides 7 positive-lock screw length settings.

Slide the stopper base out and in while depressing the

levers on the top surface of the stopper base so the

number for desired screw length (indicated on the label)

appears in the reading window. See the following table

for details on the numbers allocated to your desired

screw lengths.

►

Fig.5:

1.

Stopper base

2.

Levers

3.

Label

4.

Reading window

Numbers indicated on

the label

Screw length ranges

25

25 mm (1″)

30

25 mm - 30 mm (1″ - 1-3/16″)

35

30 mm - 35 mm (1-3/16″ - 1-3/8″)

40

35 mm - 40 mm (1-3/8″ - 1-9/16″)

45

40 mm - 45 mm (1-9/16″ - 1-3/4″)

50

45 mm - 50 mm (1-3/4″ - 2″)

55

50 mm - 55 mm (2″ - 2-3/16″)

Adjusting driving depths

Press the front face of the stopper base and hold the

feeder box down into the casing as far as it will go.

While keeping it in that position, turn the adjusting dial

so that the driver bit tip comes out approximately 6 mm

from the front face of the stopper base.

Drive a trial screw. If the screw head stands above the

workpiece surface, turn the adjusting dial in the A direc

-

tion; if the screw head sits below the surface, turn the

adjusting dial in the B direction.

►

Fig.6:

1.

Approx. 6 mm

2.

Stopper base

3.

Feeder

box

4.

Casing

5.

Adjusting dial

Switch action

WARNING:

Before installing the battery car-

tridge into the tool, always check to see that the

switch trigger actuates properly and returns to

the "OFF" position when released.

To start the tool, pull the switch trigger. Tool speed is

increased by increasing pressure on the switch trigger.

Release the switch trigger to stop.

For continuous operation, pull the switch trigger, push in

the lock button and then release the trigger. To stop the

tool from the locked position, pull the switch trigger fully,

and then release it.

►

Fig.7:

1.

Switch trigger

2.

Lock button