5 / 9

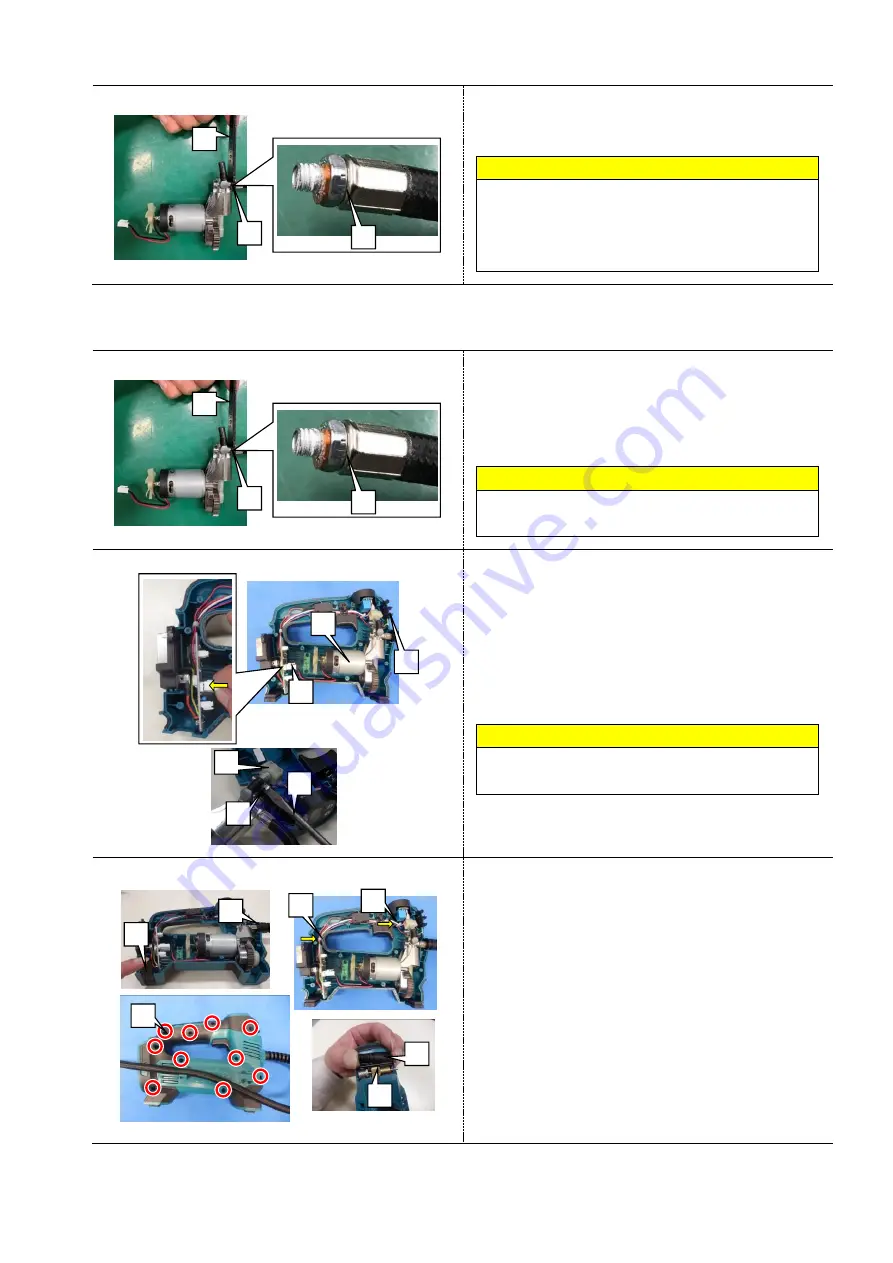

Fig.4

7

Loosen and remove Hose [1] with Wrench 10 [2]

(781036-5).

Note

Only a thin wrench [2] can be inserted, so be

careful when loosening.

As adhesive is applied to the thread on Hose end, be

careful when you loosen it.

4-2-2

Assembling

Fig.5

1

Remove the old screw lock adhesive on the thread

of Hose end [1], then apply a high strength

adhesive (Loctite 272), and then tighten the joint

portion with Wrench 10 [2] (781036-5).

Note

Only a thin wrench can be inserted, so be careful

when tightening.

Fig.6

2

Connect Lead wires of Motor assembly [1] to the

connector of PCB [2].

3

Insert the tube on the side of Pressure sensor [3]

into Pump section. Assemble Clamp [5], then

tighten the screw with a slotted screwdriver [4].

Assemble Fixed bracket [6].

Note

When inserting the tube, be careful to tighten it

because only a thin wrench can be inserted.

4

Assemble Motor assembly [1] to Housing.

Fig.7

5

Assemble Mats [1] (2 pcs). Assemble the pipe

guard of Air pipe assembly [2] to Housing.

6

Bundle Lead wires with Cable ties [3], [4].

7

Align Housing R with Housing L, then tighten

Screws 3x14 [5] (10 pcs).

8

Assemble Swim ring adapter [6] and Ball adapter

[7] to Fixed bracket.

[3]

[4]

[2]

[1]

[5]

[6]

[7]

[1]

[6]

[2]

[3]

[5]

[4]

[1]

[1]

[2]

[1]

[1]

[2]