9

9

0

When using synthetic resin cutting discs, always ob-

serve the following:

CAUTION

:

- Synthetic resin cutting discs can absorb moisture. This

moisture can cause the disc to become unbalanced at high

speed. This imbalance can cause the disc to break.

- Do not cool resin cutting discs with water or other fluids.

- Do not expose resin cutting discs to high humidity or

rain!

Do not use resin cutting discs past their use-by date (expira-

tion date)! The date (quarter and year) is stamped on the disc’s

arbor ring.

EXAMPLE: 04 / 2007

This cutting disc can be used through the end of the fourth quarter

of 007, if properly stored and correctly used.

Cutting metals

IMPORTANT!

Always wear approved respiratory protection!

Materials that can release toxic substances may be cut only

after notifying the proper authorities and under their supervi-

sion or that of a person appointed by them.

CAUTION!

The rapid rotation of the cutting disc heats metal and melts it

at the point of contact. Swing the guard as far down as pos-

sible

(9)

in order to direct the stream of sparks forward, away

from the operator

(fire hazard).

- Determine the cut line, mark the cut and apply the disc to the

material at moderate speed, to cut a guide groove before going

to top speed and applying more pressure to the Power Cut.

- Keep the disc straight and vertical. Do not tip it, as this can

break it.

- The best way to get a good, clean cut is to pull or move the

Power Cut back and forth. Do not simply press the disc into

the material.

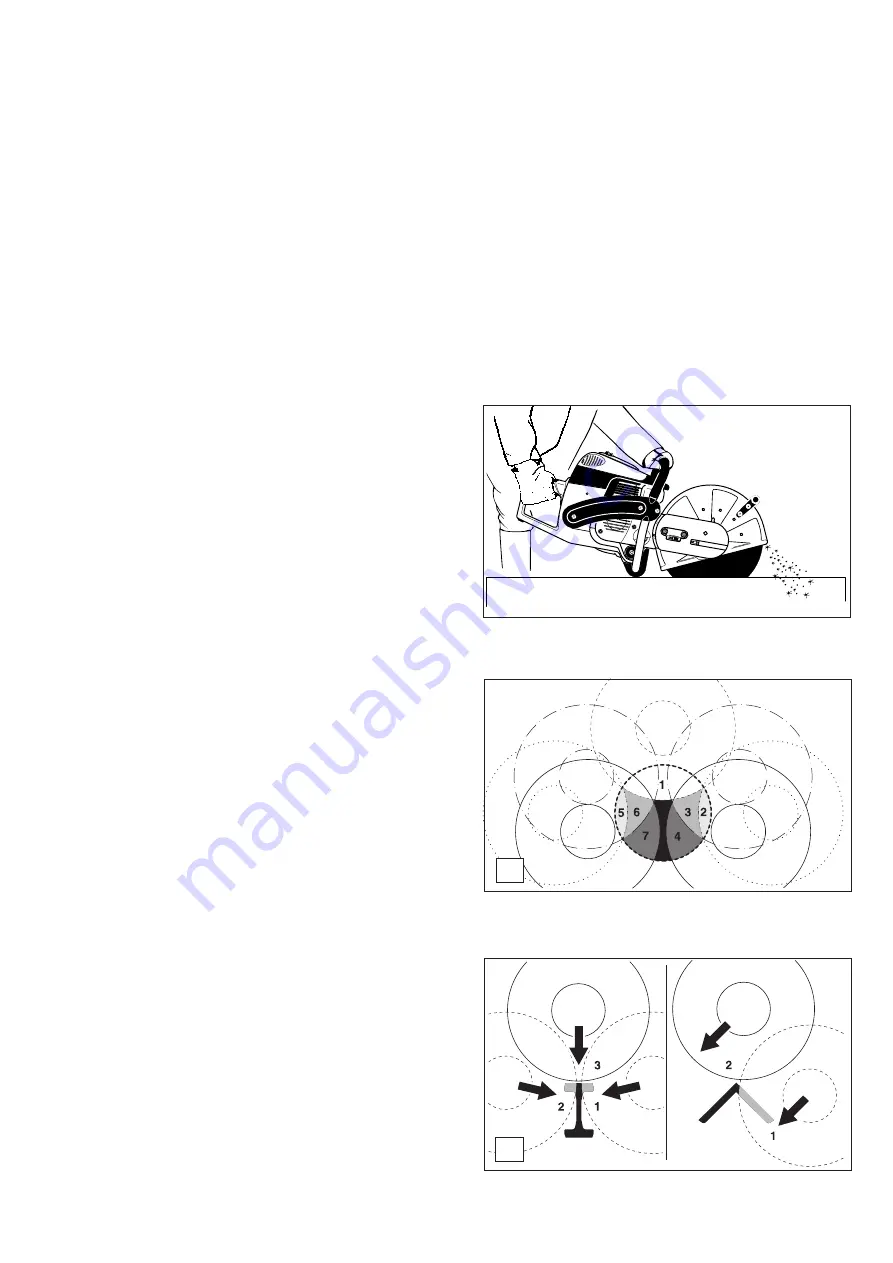

- Thick round stock is best cut in stages (0).

- Thin tubing and pipes can be cut with a simple downward

cut.

- Cut large-diameter pipes as for round stock. To prevent tipping

and for better control, do not let the disc sink too deeply into

the material. Instead, always cut shallow around the whole

piece.

- Worn discs have a smaller diameter than new discs, so that at

the same engine speed they have a lower effective circumfer-

ential speed and therefore do not cut as well.

- Cut I-beams and L-bars in steps; see Figure .

- Cut bands and plates like pipes: along the wide side with a long

cut.

- When cutting material under stress (supported material or mate-

rial in structures), always make a notch in the thrust (pressure)

side, and then cut from the tension side, so that the disc does

not lock in.

Secure cutoff material from falling!

CAUTION!

If there is a chance that the material is under stress, be pre-

pared for it to kick back. Make sure you can get out of the

way if you have to!

Be particularly careful in scrap-metal yards, junkyards, at ac-

cident sites, and with haphazard piles of material. Precariously

balanced pieces or pieces under stress can act in unpredictable

ways, and may slide, jump out, or burst. Secure cutoff material

from falling! Always exercise extreme caution and use only

equipment that is in perfect working order.

Observe the accident-prevention rules and regulations of your

employer and/or insurance organization.

Cutting masonry and concrete

IMPORTANT!

Always wear approved respiratory protection!

Asbestos and other materials that can release toxic sub-

stances may be cut only after notifying the proper authorities

and under their supervision or that of a person appointed

by them. When cutting prestressed and reinforced concrete

piles, follow the instructions and standards of the respon-

sible authorities or the builder of the structural member.

Reinforcement rods must be cut in the prescribed sequence

and in accordance with applicable safety regulations.

NOTE:

Mortar, stone, and concrete develop large quantities of dust during

cutting. To increase the lifetime of the cutting disc (by cooling),

to improve visibility, and to avoid excessive dust creation, we

strongly recommend wet cutting instead of dry cutting.