10

5. Release the switch trigger when the cut is completed

and the Cutter Rod has reached the end of its stroke.

The Cutter Rod will then return automatically to its

starting position. The Cutter Rod will not return if the

stroke is not completed. Similarly the Cutter Rod will

not be able to move forward again until after it returns

completely to its starting position. Press the switch to

start the next cut, only after the Cutter Rod completely

returns to its starting position and stops.

WARNING

• When cutting rebar of a high tensile strength the cut

piece may fly off and cause serious injury to the

operator. Wear safety glasses and confirm that the

surrounding area is safe before starting operation.

(Fig. 10)

WARNING

• Keep your hands and face away from the blades, the

moving parts and the cutting area, during operation.

Remove the Battery from the tool immediately after

use.

NOTE:

• Keep the air hole in the end of the Bar Holder clear of

dirt and debris. The air hole controls the internal

pressure and should not be obstructed.

(Fig. 11)

Rotating Function of Motor (Fig. 12)

The Motor Body can be rotated through 360 degrees, in

either direction, during operation. This feature is

particularly useful when working in awkward or narrow

areas as it allows the operator to position the tool in the

best position for easy operation.

Return Valve Operation (Fig. 13)

The function of the Return Valve is to allow the Cutter Rod

to return to the starting position if it is unable complete a

cut or becomes jammed. This will release the oil pressure

and allow the Cutter Rod to return. Retighten the Return

Valve once the Cutter Rod is fully returned and before

starting the next operation.

BLADES REPLACEMENT

PROCEDURE

If the cutting edges of the blades are chipped, cracked,

deformed, or damaged in any way, their cutting ability will

be reduced. Cutting under such conditions may cause

further damage and result in personal injury. The blades

should be replaced as a set immediately if any damage is

found.

WARNING

• When replacing the blades, ensure that the Battery is

removed from the tool to prevent accidental operation.

Ensure that Blade A, on the Bar Holder and Blade B, on

the Cutter Rod are fitted in their correct respective

positions.

(Fig. 14)

1. Undo the bolts and the washers that hold Blade A and

Blade B.

2. Remove dirt and clean the surfaces where the new

blades are to be fitted.

3. Fit Blade A to the Bar Holder and Blade B to the Cutter

Rod. Replace bolts and washers and tighten firmly.

WARNING

• The bolts that hold Blade A and Blade B should be

tightened regularly. If the bolts become loose the

Blades may be damaged and may cause personal

injury.

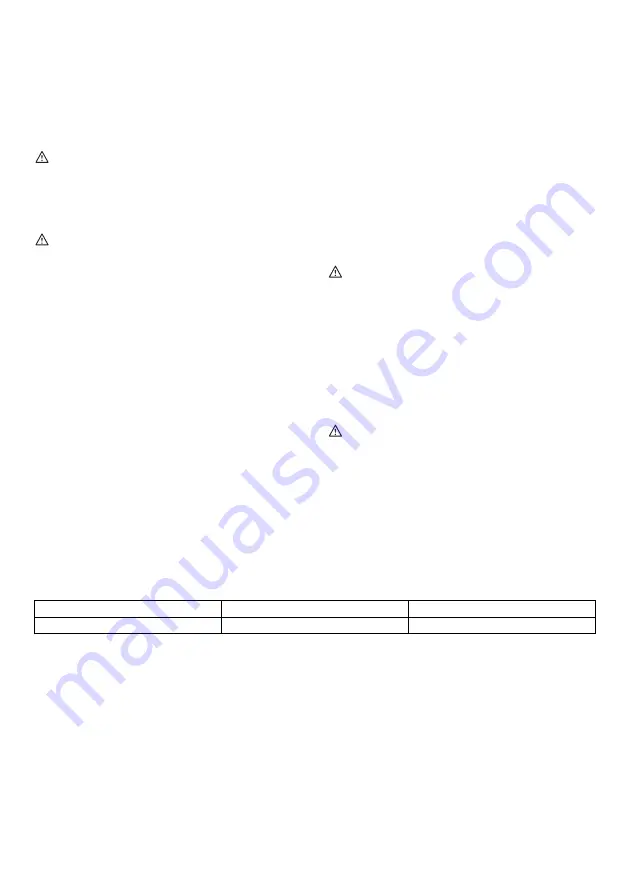

Type of spare blade and detachment

(Fig. 15)

Securing bolts should be firmly tightened.

Confirm periodically that the blade is tightened properly.

Spare blade size

Use this table to identify the correct blades for your model.

NOTE:

• Use only genuine Makita blades.

ADDING OIL

This cordless rebar cutter is electro-hydraulic. When

shipped from the factory, it was filled with oil. Do not

attempt to add oil as long as the tool performs well. Over a

period of time the oil level will gradually go down.

Eventually this will cause a noticeable dropping off in

performance. When this happens add oil as follows.

1. Place some rebar between the blades and pull the

switch trigger.

2. Release the switch trigger just before the cut is

completed to stop the tool.

3. Remove the Battery from the tool, so that the Blades

cannot be moved accidentally.

4. Remove the Bolt (SB10x15) which caps the oil filler

hole. Add the oil, being careful not to allow any oil to

spill into the motor.

5. Replace the Bolt (SB10x15) and tighten securely.

6. Reinsert the Battery into the tool and complete the

cutting operation.

7. Repeat the above procedure several times until the oil

level remains correct.

Model

A (Fitted to Bar Holder)

B (Fitted to Cutter Rod)

DSC191 (ø3 - ø20)

28 × 20 × 11.5 mm (Bolt Size 6 mm)

26 × 20 × 10 mm (Bolt Size 5 mm)