13 ENGLISH

Speed adjusting dial

►

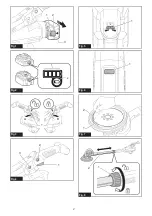

Fig.5:

1.

Speed adjusting dial

The rotation speed of the tool can be changed by turn

-

ing the speed adjusting dial. The table below shows

the number on the dial and the corresponding rotation

speed.

Number

Speed

1

1,000 min

-1

2

1,200 min

-1

3

1,400 min

-1

4

1,600 min

-1

5

1,800 min

-1

NOTICE:

The speed adjusting dial can be turned

only as far as 5 and back to 1. Do not force it past

5 or 1, or the speed adjusting function may no

longer work.

Overload and overheat indicator

lamp

►

Fig.6:

1.

Indicator lamp

If the tool is operated with excessive load, the tool stops

automatically and the indicator lamp blinks in red. In this

case, reduce the load on the tool.

If the tool is overheated, the tool stops automatically

and the indicator lamp lights up in red. In this case, let

the tool cool down before turning the tool on again.

Electronic function

The tools equipped with electronic function are easy to

operate because of the following features.

Constant speed control

Possible to get fine finish, because the rotating speed is

kept constant even under the loaded condition.

Soft start feature

Soft start because of suppressed starting shock.

ASSEMBLY

CAUTION:

Always be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

Installing the abrasive disc

►

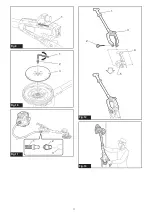

Fig.7:

1.

Abrasive disc

2.

Pad

Remove any dirt or foreign matter from the pad, and

then attach the abrasive disc to the pad while aligning

the holes in the abrasive disc with those in the pad.

Adjusting the pipe length

CAUTION:

When adjusting the pipe length,

hold the tool horizontally.

Otherwise, the pipe

length may change unintentionally and it may cause

an injury or malfunction of the tool.

NOTICE:

Do not extend the pipe beyond the

limit.

Failure to do so may cause a malfunction of

the tool.

►

Fig.8:

1.

Sleeve

2.

Pipe

To adjust the pipe length, loosen the sleeve, then adjust

the length of the pipe, and then tighten the sleeve.

Hex wrench storage

►

Fig.9:

1.

Hex wrench

When not in use, store the hex wrench as shown in the

figure to keep it from being lost.

Installing or removing the pad

►

Fig.10:

1.

Hex wrench

2.

Bolt

3.

Pad

To remove the pad, remove the abrasive disc from the

pad, and then turn the bolt counterclockwise with a hex

wrench. To install the pad, perform the removal proce-

dure in reverse.

CAUTION:

Make sure that the pad is secured

properly.

Loose attachment will run out of balance

and cause an excessive vibration which may cause

loss of control.

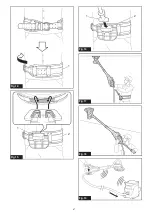

Connecting a vacuum cleaner

Optional accessory

When you wish to perform operation cleanly, connect a

Makita vacuum cleaner to your tool. Connect a hose of

the vacuum cleaner to the dust nozzle using the front

cuff 24.

►

Fig.11:

1.

Hose of the vacuum cleaner

2.

Front cuff

24

3.

Dust nozzle

Installing or removing the extension

handle

Optional accessory

To install the extension handle, attach the extension

handle to the tool and secure it with the knob firmly. Be

sure to insert the end of the tool into the holder of the

extension handle. To remove the extension handle,

perform the installation procedure in reverse.

►

Fig.12:

1.

Extension handle

2.

Knob

3.

Holder

4.

End of tool

5.

Mounting hole

WARNING:

Use the mounting hole of the tool

only for attaching the extension handle.

Using the mounting hole for any other purpose may

cause an unexpected accident.

Summary of Contents for DSL801

Page 2: ...1 2 3 Fig 1 1 2 Fig 2 1 A B Fig 3 1 2 3 Fig 4 1 Fig 5 1 Fig 6 1 2 Fig 7 2 1 Fig 8 2 ...

Page 3: ...1 Fig 9 1 2 3 Fig 10 1 2 3 Fig 11 1 2 3 4 5 Fig 12 Fig 13 3 ...

Page 4: ...1 Fig 14 1 2 Fig 15 1 2 Fig 16 Fig 17 Fig 18 Fig 19 4 ...

Page 5: ...1 Fig 20 1 2 3 4 Fig 21 1 2 3 Fig 22 1 Fig 23 1 2 2 1 Fig 24 Fig 25 5 ...

Page 6: ...1 Fig 26 2 1 Fig 27 1 Fig 28 1 Fig 29 1 2 2 1 Fig 30 1 2 Fig 31 6 ...

Page 7: ...1 3 2 Fig 32 7 ...