8 ENGLISH

Procedure 2

Optional accessory

In addition to

Procedure 1

, insert the bit-piece into the

sleeve with its pointed end facing in.

►

Fig.8:

1.

Driver bit

2.

Bit-piece

3.

Sleeve

To remove the driver bit, pull the sleeve in the direction

of the arrow and pull the driver bit out.

NOTE:

If the driver bit is not inserted deep enough

into the sleeve, the sleeve will not return to its original

position and the driver bit will not be secured. In this

case, try re-inserting the bit according to the instruc

-

tions above.

NOTE:

When it is difficult to insert the driver bit, pull

the sleeve and insert it into the sleeve as far as it will

go.

NOTE:

After inserting the driver bit, make sure that it

is firmly secured. If it comes out, do not use it.

Installing hook

WARNING:

Use the hanging/mounting parts

for their intended purposes only, e.g., hanging the

tool on a tool belt between jobs or work intervals.

WARNING:

Be careful not to overload the

hook as too much force or irregular overburden

may cause damages to the tool resulting in per-

sonal injury.

CAUTION:

When installing the hook, always

secure it with the screw firmly.

If not, the hook

may come off from the tool and result in the personal

injury.

CAUTION:

Make sure to hang the tool

securely before releasing your hold.

Insufficient

or unbalanced hooking may cause falling off and you

may be injured.

►

Fig.9:

1.

Groove

2.

Hook

3.

Screw

The hook is convenient for temporarily hanging the tool.

This can be installed on either side of the tool. To install

the hook, insert it into a groove in the tool housing on

either side and then secure it with a screw. To remove,

loosen the screw and then take it out.

Using hole

WARNING:

Never use the hanging hole for

unintended purpose, for instance, tethering the

tool at high location.

Bearing stress in a heavily

loaded hole may cause damages to the hole, result

-

ing in injuries to you or people around or below you.

►

Fig.10:

1.

Hanging hole

Use the hanging hole at the bottom rear of the tool to

hang the tool on a wall using a hanging cord or similar

strings.

OPERATION

►

Fig.11

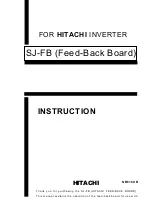

The proper fastening torque may differ depending upon

the kind or size of the screw/bolt, the material of the

workpiece to be fastened, etc. The relation between fas-

tening torque and fastening time is shown in the figures.

Proper fastening torque for standard bolt

2

1

N•m

(kgf•cm)

160

(1632)

140

(1428)

120

(1224)

100

(1020)

80

(816)

60

(612)

40

(408)

20

(204)

0

M14

M12

(M14)

(M16)

(M12)

(M10)

(M8)

M10

M8

2.0

3.0

4.0

1.0

1.

Fastening time (second)

2.

Fastening torque

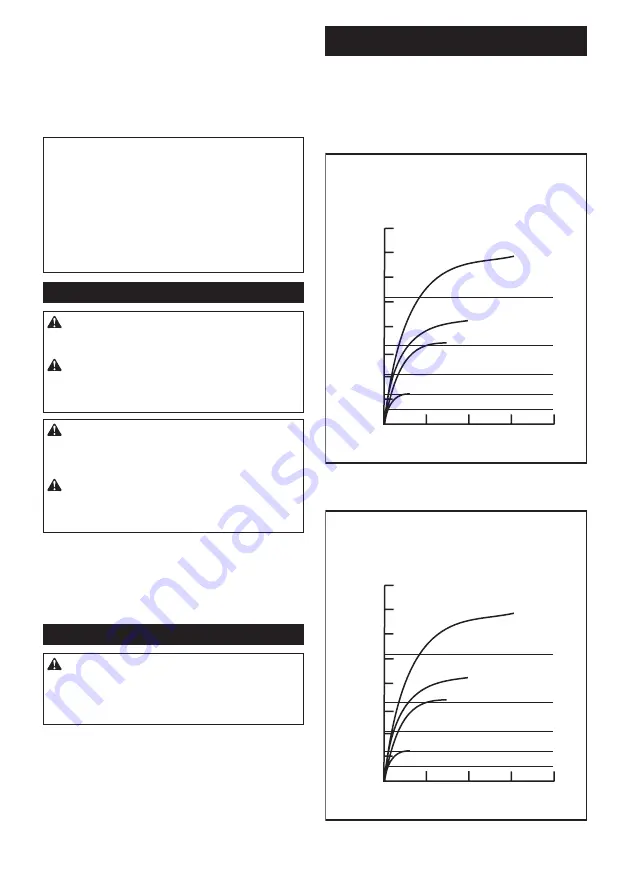

Proper fastening torque for high tensile bolt

2

1

N•m

(kgf•cm)

160

(1632)

140

(1428)

120

(1224)

100

(1020)

80

(816)

60

(612)

40

(408)

20

(204)

0

M14

M12

(M14)

(M16)

(M12)

(M10)

(M8)

M10

M8

2.0

3.0

4.0

1.0

1.

Fastening time (second)

2.

Fastening torque