4 ENGLISH

3.

Check damaged parts before further use of

the tool. A guard or other part that is damaged

should be carefully checked to determine

that it will operate properly and perform its

intended function. Check for alignment of

moving parts, binding of moving parts, break-

age of parts, mounting, and any other condi-

tion that may affect its operation. A guard or

other part that is damaged should be properly

repaired or replaced by our authorized ser-

vice center unless indicated elsewhere in this

manual.

4.

Switch on the motor only when hands and feet

are away from the cutting tool.

5.

Before starting make sure that the cutting

tool has no contact with hard objects such as

branches, stones etc. as the cutting tool will

revolve when starting.

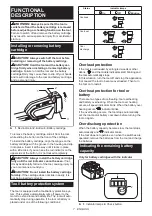

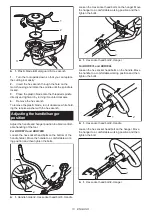

Method of operation

1.

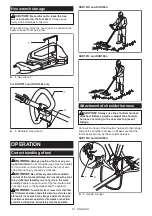

Never operate the machine with damaged

guards or without the guards in place.

2.

Only use the tool in good light and visibility.

During the winter season beware of slippery

or wet areas, ice and snow (risk of slipping).

Always ensure a safe footing.

3.

Take care against injury to feet and hands from

the cutting tool.

4.

Keep hands and feet away from the cutting

means at all times and especially when switch-

ing on the motor.

5.

Never cut above waist height.

6.

Never stand on a ladder and run the tool.

7.

Never work on unstable surfaces.

8.

Don't overreach. Keep proper footing and

balance at all times.

9.

Remove sand, stones, nails etc. found within

the working range. Foreign particles may

damage the cutting tool and can cause to be

thrown away, resulting in a serious injury.

10.

Should the cutting tool hit stones or other hard

objects, immediately switch off the motor and

inspect the cutting tool.

11.

Before commencing cutting, the cutting tool

must have reached full working speed.

12.

During operation always hold the tool with

both hands. Never hold the tool with one hand

during use. Always ensure a safe footing.

13.

All protective equipment such as guards

supplied with the tool must be used during

operation.

14.

Except in case of emergency, never drop

or cast the tool to the ground or this may

severely damage the tool.

15.

Never drag the tool on the ground when mov-

ing from place to place, the tool may become

damaged if moved in this manner.

16.

Always remove the battery cartridge from the

tool:

—

whenever leaving the tool unattended;

—

before clearing a blockage;

—

before checking, cleaning or working on

the tool;

—

before making any adjustments, chang-

ing accessories or storing;

—

whenever the tool starts vibrating

unusually;

—

whenever transporting the tool.

17.

Don't force the tool. It will do the job better and

with less likelihood of a risk of injury at the

rate for which it was designed.

18.

Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases or dust.

Power tools create sparks

which may ignite the dust or fumes.

19.

Take a rest to prevent loss of control caused

by fatigue.

We recommend to take a 10 to

20-minute rest every hour.

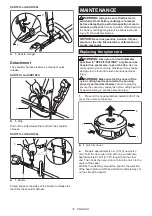

Maintenance instructions

1.

The condition of the cutting tool, protective

devices and shoulder strap must be checked

before commencing work.

2.

Turn off the motor and remove the battery

cartridge before carrying out maintenance,

replacing the cutting tool and cleaning the

tool.

3.

After use, disconnect the battery cartridge

from the tool and check for damage.

4.

Check for loose fasteners and damaged parts

such as nearly halfway cut-off state in the

cutting tool.

5.

When not in use store the equipment in a dry

location that is locked up or out of children's

reach.

6.

Use only the manufacturer's recommended

replacement parts and accessories.

7.

Always ensure that ventilation openings are

kept clear of debris.

8.

Inspect and maintain the tool regularly, espe-

cially before/after use. Have the tool repaired

only by our authorized service center.

9.

Keep handles dry, clean and free from oil and

grease.

SAVE THESE INSTRUCTIONS.

WARNING:

DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause

serious personal injury.

Important safety instructions for

battery cartridge

1.

Before using battery cartridge, read all instruc-

tions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using

battery.

2.

Do not disassemble battery cartridge.

3.

If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

Summary of Contents for DUR187U

Page 18: ...18 ...

Page 19: ...19 ...

Page 20: ...Makita Corporation www makita com 885546C5 EN 20170206 ...