March 2016

T

ECHNICAL INFORMATION

OFFICIAL USE

for ASC & Sales Shop

C

ONCEPT AND MAIN APPLICATIONS

Straight gasoline (lead-free gasoline for automobiles)

Nylon cutting head

0.5

24.5

Fuel tank capacity: L

Standard cutting tool

Engine Displacement: mL

Fuel

4-stroke

Specification

EBH252L

Model

Type

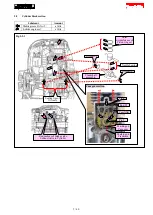

Starting system

Recoil starter, with mechanical decompression

Loop handle

Handle style

Engine oil

Carburetor

SAE10W-30 oil

in the Class SF or higher of API Classification

Diaphragm

Net weight

*

2

: kg (lbs)

5.2 (11.5)

*1

No load speed of the engine when installed on the brushcutter

*2

Dry weight, without universal guard, cutting tool and shoulder harness

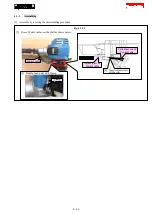

Rapid start

Nylon cutting head

EBH253L

EBH253U

Loop handle

5.3 (11.7)

No

230mm (9")

diameter

4-tooth star blade

EBH252U

Bike handle

5.7 (12.6)

No

No

230mm (9")

diameter

4-tooth star blade

9,000

No load speed

*

1

: min-

ı

= rpm

9,000

10,000

10,000

Bike handle

5.9 (13.0)

Yes

Yes

Waist cushion

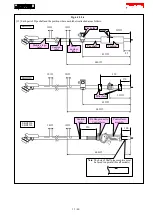

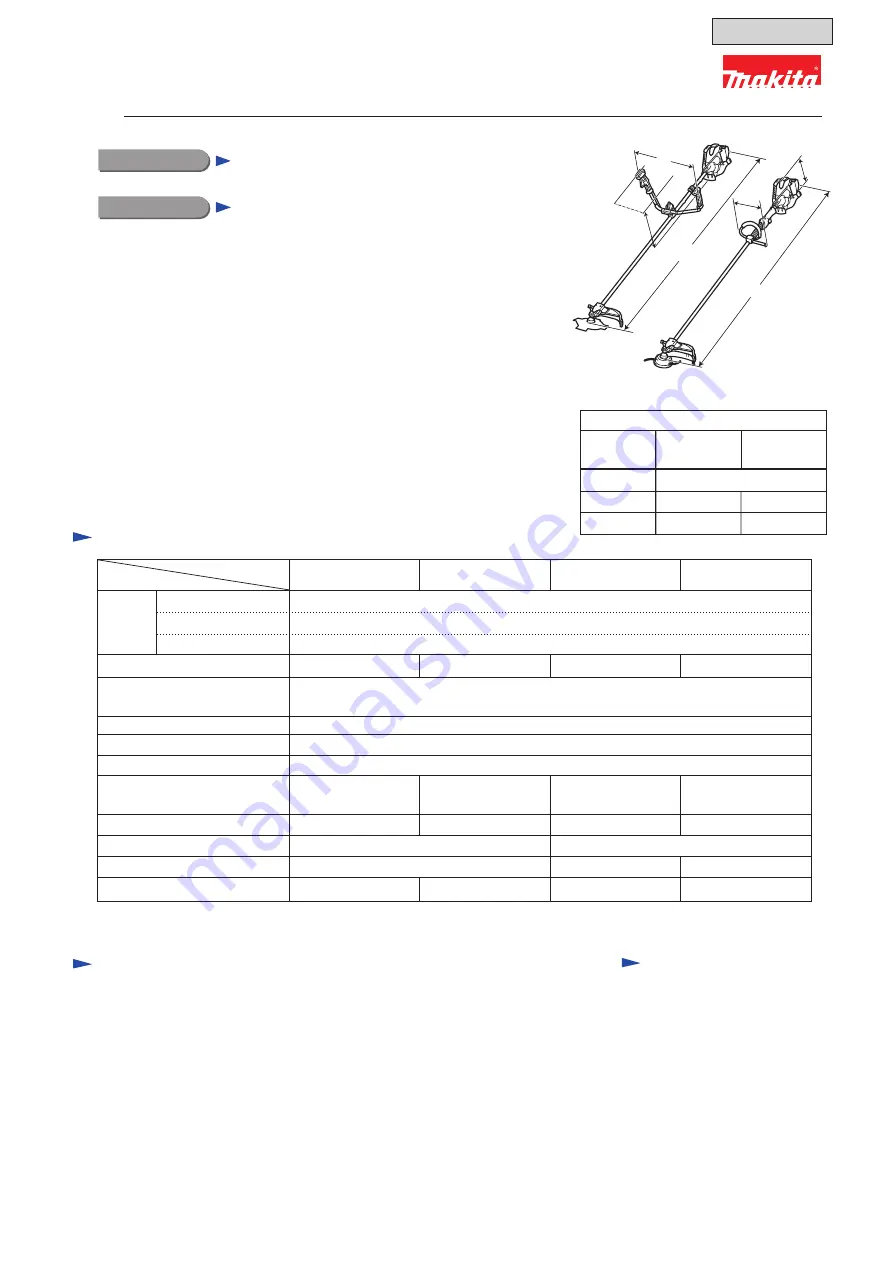

620 (24-3/8)

330 (13)

L

W

H

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

1,770 (69-3/4)

490 (19-1/4) 265 (10-3/8)

EBH252U

EBH253U

EBH252L

EBH253L

EBH252U

EBH253U

EBH252L

EBH253L

L

W

H

EBH252U, EBH252L

EBH253U, EBH253L

Petrol Brushcutter

These four models are 4-stroke petrol brushcutters developed

in compliance with EU Stage 2 exhaust emission regulations.

Their main features are:

• 4-stroke engine for low noise and clean exhaust emission

• Ergonomic handle for higher maneuverability

See “Specification” below for the specification differences

between the four models.

Note:

These four products are not in compliance with

the regulations of San Dimas.

1 / 40

Model No.

Description

S

pecification

S

tandard equipment

Blades, Nylon cutting head

O

ptional accessories

Note:

The standard equipment for the tool shown above may vary by country.

4-tooth star blade 230mm (9") (for EBH252U, EBH253U)

Nylon cutting head (for EBH252L, EBH253L)

Universal guard (=Protector)

Shoulder harness with double shoulder straps (for EBH252U, EBH253U)

Shoulder harness with single shoulder strap (for EBH252L, EBH253L)

Socket wrench

Hex wrench (for M5)

Hex wrench (for M6)

Wire clamp (for tying cables) (for EBH252U)

Oil bottle