13

PUTTING INTO OPERATION

CAUTION:

Always turn off the engine and pull off the spark plug cap

before doing any work on the Power Cutter! Always wear

protective gloves!

CAUTION:

Start the Power Cutter only after complete assembly and

inspection.

Mounting the cutting disc

WARNING:

When installing a diamond cutting disc, be sure to mount

•

it so that the arrow is in the same direction as the outer

flange (6) rotates.

Mounting the diamond cutting disc

(4)

with

its arrow direction opposite to that on the wheel cover may

cause chipping of the disc edge and personal injury.

When installing a cutting disc (4), always use the ring that

•

matches the bore of the cutting disc and the diameter of

the spindle (5).

Failure to use rings that mate may cause tool

vibration resulting in serious personal injury.

Only use cutting discs with the bore that matches the

•

diameter of the ring(s) provided.

Using discs that do not mate

may cause tool vibration resulting in serious personal injury.

Inspect a cutting disc for damage. (see the section titled

•

“Cutoff discs” in SAFETY PRECAUTIONS.)

1. Insert the star-shaped wrench

(2)

into the hole

(8)

to prevent

the spindle

(5)

from rotating.

NOTE

: When the holder of the pressure water system is installed

in the hole in the tool, remove it before mounting the

cutting disc.

2. While holding on the wrench

(2)

in that position, use the

combination wrench

(1)

provided and turn the bolt

(7)

securing

the disc counterclockwise and remove the bolt

(7)

and outer

flange

(6)

.

3. Mount a diamond cutting disc/cut-off abrasive disc

(4)

on the

arbor

(5)

. And then put the outer flange

(6)

on the spindle

so that the two parallel flat surface on the outer flange fit the

spindle flat surface and firmly tighten the bolt clockwise.

To install a cutting disc, mount a ring with the same matching

diameter as the disc bore and the O ring provided to retain the

ring on the spindle before installing a diamond cutting disc.

And then install the cutting disc.

NOTE

: Tighten the hex bolt firmly (25 - 31 Nm), as otherwise the

cutting wheel may slip during cutting.

4

5

6

7

6

1

8

2

Schematic

drawing

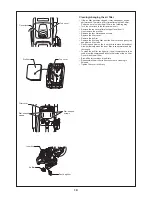

For the following work, use the assembly tools included with

delivery:

1. 13/16 AF combination wrench

2. Star-sharped wrench

3. Carburetor adjustment screwdriver

4. Adapter ring

Place the Power Cutter on a stable surface and carry out the

following assembly steps:

No air filter is installed!

Before operation, squeeze the supplied filter several times so

that oil is evenly immersed in the entire filter. Insert an oiled

foam filter (pre-filter), as shown in the adjacent illustration! To

do this, take off the filter cover (see the chapter on Cleaning/

changing the air filter).

Summary of Contents for EK7650H

Page 27: ...27...

Page 28: ...Makita Corporation 885023C7 www makita com ALA...