24

Maintenance chart

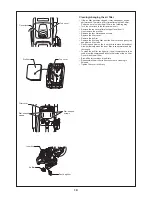

Item

Inspecting

Regularity

Engine oil

Inspection/clean

Before commencing work

Replace

Initially, after 20 operating hours, and

subsequently every 30 operating hours

Wheel, tightening bolt, hood

Visual inspection

Before commencing work

Throttle system

Functional check

Before commencing work

Air filter

Gently tap or replace.

Monthly (every 50 operating hours)

Dust bag filter

Clean or replace.

Weekly (every 20 operating hours)

Prefilter

Rinse off coarse dirt in running water or

replace, and apply oil.

Daily (every 8 operating hours)

Spark plug

Visual check … Clean, adjust, or replace

Implement as you think proper

V-belt

Visually inspect status of wear (take

care about excessive tension at time of

replacement).

Before commencing work

Fuel tank filter

Visually inspect, and replace depending on

level of dirtiness.

Implement as you think proper

Nuts and bolts

Visually inspect, and correct.

Before commencing work

Be sure to use designated and genuine parts and consumables.

•

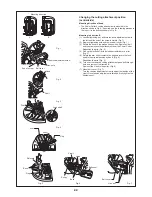

Fault location

Fault

System

Observation

Cause

Cutting disc does not

start turning

Clutch

Engine runs

Damage to clutch

Engine does not start

or with difficulty

Ignition system

Ignition spark O.K.

Fault in fuel supply or compression system, mechanical defect

No ignition spark

STOP-switch operated, wiring fault or short circuit, spark plug or

connector defective, ignition module faulty

Fuel supply

Fuel tank filled

Incorrect choke position, carburetor defective, fuel supply line bent or

blocked, fuel dirty

Compression system No compression when

pulled over

Cylinder bottom gasket defective, crankshaft seals damaged, cylinder

or piston rings defective or improper sealing of spark plug

Mechanical fault

Starter not engaging

Broken starter spring, broken parts inside of the engine

Clutch

Contamination

adheres to clutch and

around parts

Ratchet spring contaminated and opened, have it cleaned

Warm start problems

Carburetor

Tank filled, ignition

spark existing

Carburetor contaminated, have it cleaned

Engine starts, but dies

immediately

Fuel supply

Tank filled

Incorrect idling adjustment, suction head or carburetor contaminated

Fuel tank vent defective, fuel supply line interrupted, cable or STOP-

switch faulty

Insufficient

performance

Several systems may

simultaneously be

affected

Engine idling poor

Air filter contaminated, carburetor contaminated, muffler clogged,

exhaust duct in the cylinder clogged

Summary of Contents for EK7650H

Page 27: ...27...

Page 28: ...Makita Corporation 885023C7 www makita com ALA...