7

Kickback and lock-in

When working with the Power Cutter there is a danger of kickback and lock-in.

-

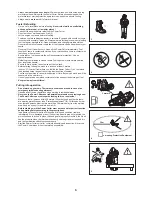

Kickback occurs when the top of the cutting disc is used for cutting (15).

-

This causes the Power Cutter to be thrown back toward the user with great force

-

and out of control.

Risk of injury!

To prevent kickback, observe the following:

Never cut with the section of the cutting disc shown in figure 15.

-

Be especially careful when reinserting the disc into cuts that have already

been started!

Lock-in occurs when the cut narrows (crack, or workpiece under stress).

-

This causes the Power Cutter to suddenly jump forward, out of control and with

-

great force.

Risk of injury!

To prevent lock-in, observe the following:

When reinserting the disc into previous cuts, have the Power Cutter running at

-

top speed. Always cut at top speed.

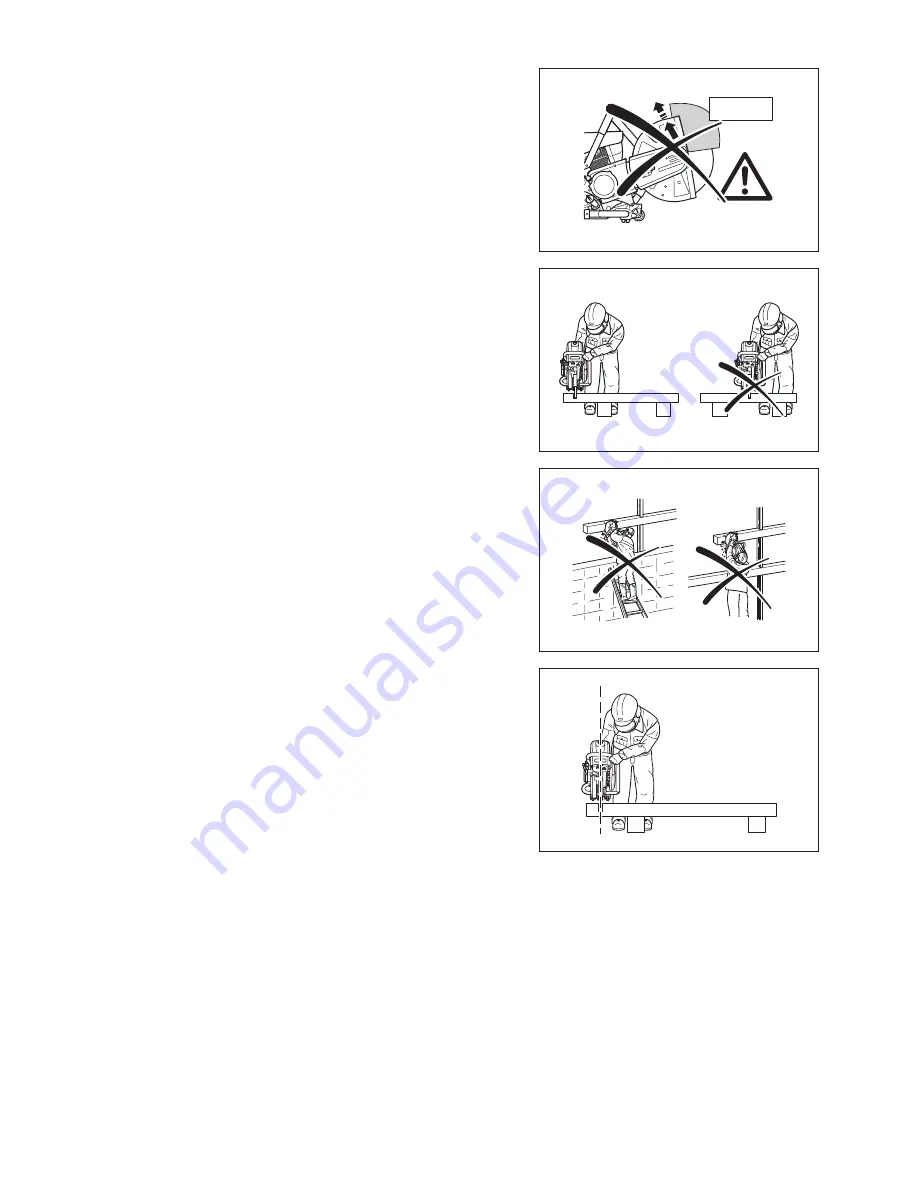

Always support the workpiece so that the cut is under tension (16), so that the

-

cut does not press together and jam the cutting disc as it proceeds through the

material.

When starting a cut, apply the disc to the workpiece with care.

-

Do not just shove it into the material.

Never cut more than one piece at a time! When cutting, make sure that no other

-

workpiece comes into contact.

Working behavior / Method of working

Before starting work, check the work area for any hazards (electrical wires,

-

inflammable substances). Clearly mark the work area (for example with warning

signs or by cordoning off the area).

When working with the Power Cutter hold it firmly by the front and rear handles.

-

Never leave the Power Cutter unattended!

Whenever possible run the Power Cutter at the rated arbour speed (see

-

“Technical data”).

Only use the Power Cutter during good light and visibility periods.

-

Be aware of slippery or wet areas, and of ice and snow (risk of slipping).

Never work on unstable surfaces. Make sure that there are no obstacles in the

-

working area, risk of stumbling. Always ensure that you have a safe footing.

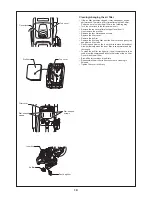

Never cut above your shoulder height (17).

-

Never stand on a ladder to cut (17).

-

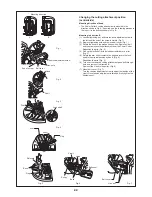

Never use the Power Cutter while standing on scaffolding.

-

Do not lean over too far when working. When putting down and picking up the

-

Power Cutter, do not bend over from the waist, but instead bend in the knees.

Save your back!

Guide the Power Cutter in such a way that no part of your body is within the

-

extended swing range of the disc (18).

Use cutting discs only for the materials for which they are designed!

-

Do not use the Power Cutter to lift up and shovel away pieces of material and

-

other objects.

Important!

Before cutting, remove all foreign objects, such as rocks, gravel, nails

etc. from the cutting area. Otherwise, such objects can be flung away by the disc

with great speed.

Injury hazard!

When cutting workpieces down to length use a firm support. If necessary, secure

-

the workpiece from slipping, but do not steady it with your foot or allow another

person to hold it.

When cutting round items, always secure them against rotation.

-

When guiding the Power Cutter by hand, use the side mounting position of the

-

cutter attachment only when actually necessary.

Otherwise, always use the central position. This gives the unit a better balance,

for reduced operator fatigue.

15

16

17

18

Summary of Contents for EK7650H

Page 27: ...27...

Page 28: ...Makita Corporation 885023C7 www makita com ALA...