P 1

0

/

19

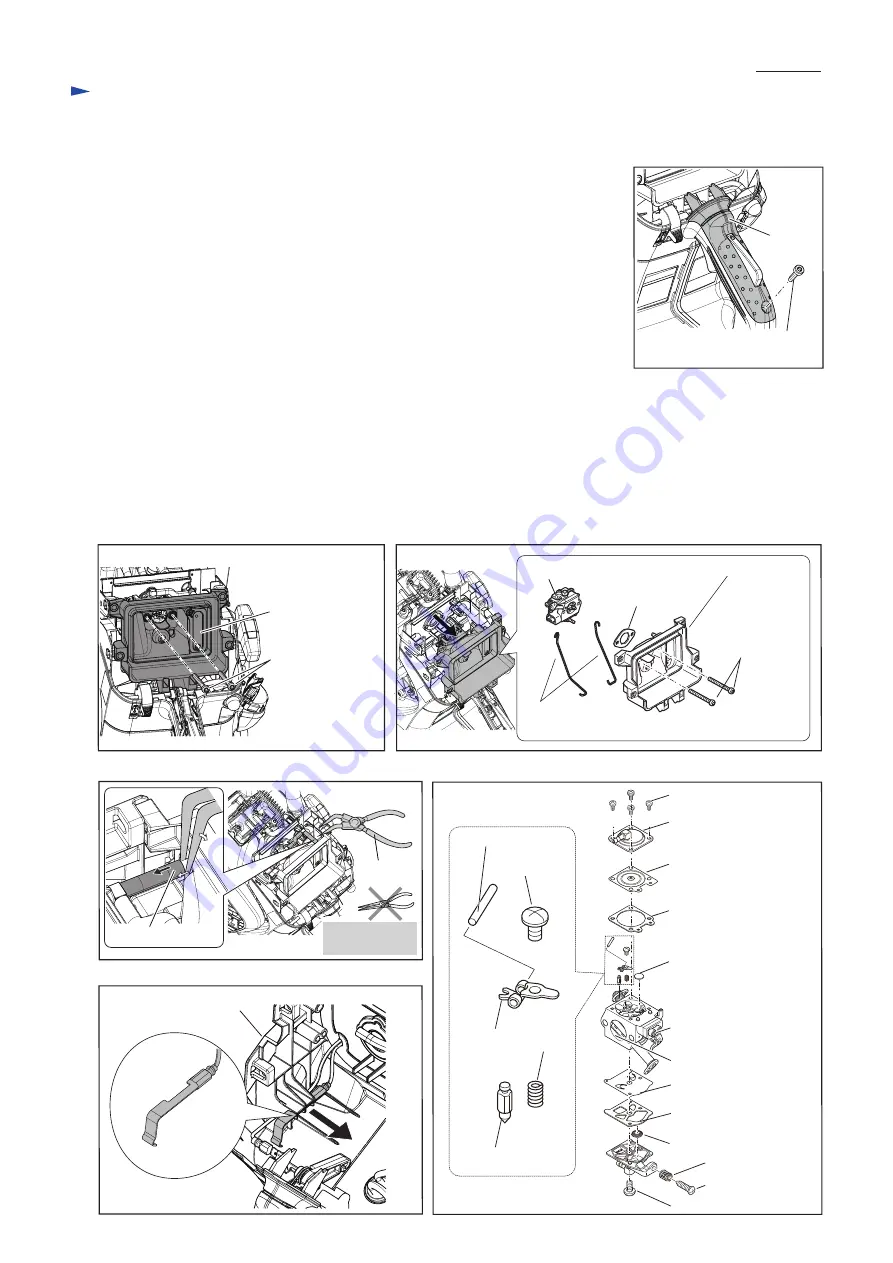

[4] DISASSEMBLY/ASSEMBLY

[4]-5. Carburetor

R

epair

Fig. 32

Fig. 33

Fig. 34

Fig. 35

Fig. 37

Fig. 36

5.5x20 Hexalobular tapping

screw

(1) After completion of the steps (1) and (2) on

[4]-4

, remove Grip cover by loosening

5.5x20 Hexalobular tapping screw. (

Fig. 32

)

(2) Loosen two M5x45 Hexalobular socket head bolts, then remove Carburetor and

Filter gasket from Carburetor mount. (

Figs. 33 and 34

)

Note

: Use 1R311 to hold/ pinch Tubes to lever it up for easy removing.

Do not use the sharp edged Pliers that causes damage to Tubes. (

Fig. 35

)

(3) Remove Contact spring. (

Fig. 36

)

(4) Carburetor WT can be disassembled as shown in

Fig. 37

.

Note

: • Check the components’ shrinkage, hardening or breakage due to aged

deterioration. If any, replace it with a new one.

• Carburetor for some countries is different from Carburetor WT. (

Fig. 37

)

The components cannot be supplied individually because of the regulation

for compliance with standards.

(5) Before mounting the inner parts of Pump body assembly in place, make sure that

the tip of Inlet needle valve is neither worn nor deformed.

Note

: The inner parts are not available individually. If you need some of the inner parts,

order Pump body assembly.

(6) Make sure that Inlet screen is not clogged, then set it back in place.

(7) Spray carburetor cleaner in all the fuel lines of Carburetor, then after several minutes,

wash out dirt and debris with clean gasoline.

Screw assembly (4 pcs.)

Inner parts of Pump

body assembly

M5x45

Hexalobular

socket head bolt

Filter bracket

Contact spring

Tank complete

1R311

Tube

The shape edges

damage Tubes.

Metering diaphragm

assembly

Metering cover

assembly

Metering diaphragm

gasket

Metering lever pin

Metering

lever

Inlet needle valve

Inlet screen

Carburetor WT

Throttle linkage

(2 pcs.)

Filter bracket

Grip cover

M5x45 Hexalo-

bular socket head

bolt (2 pcs.)

Carburetor gasket

Pump diaphragm

Pump gasket

Spring

Spring

Limiter cap

Pump body assembly

Screw

Screw

Pump body assembly

Idle adjust screw