[4] DISASSEMBLY/ASSEMBLY

[4]-5. Carburetor (cont.)

R

epair

P 1

1

/

19

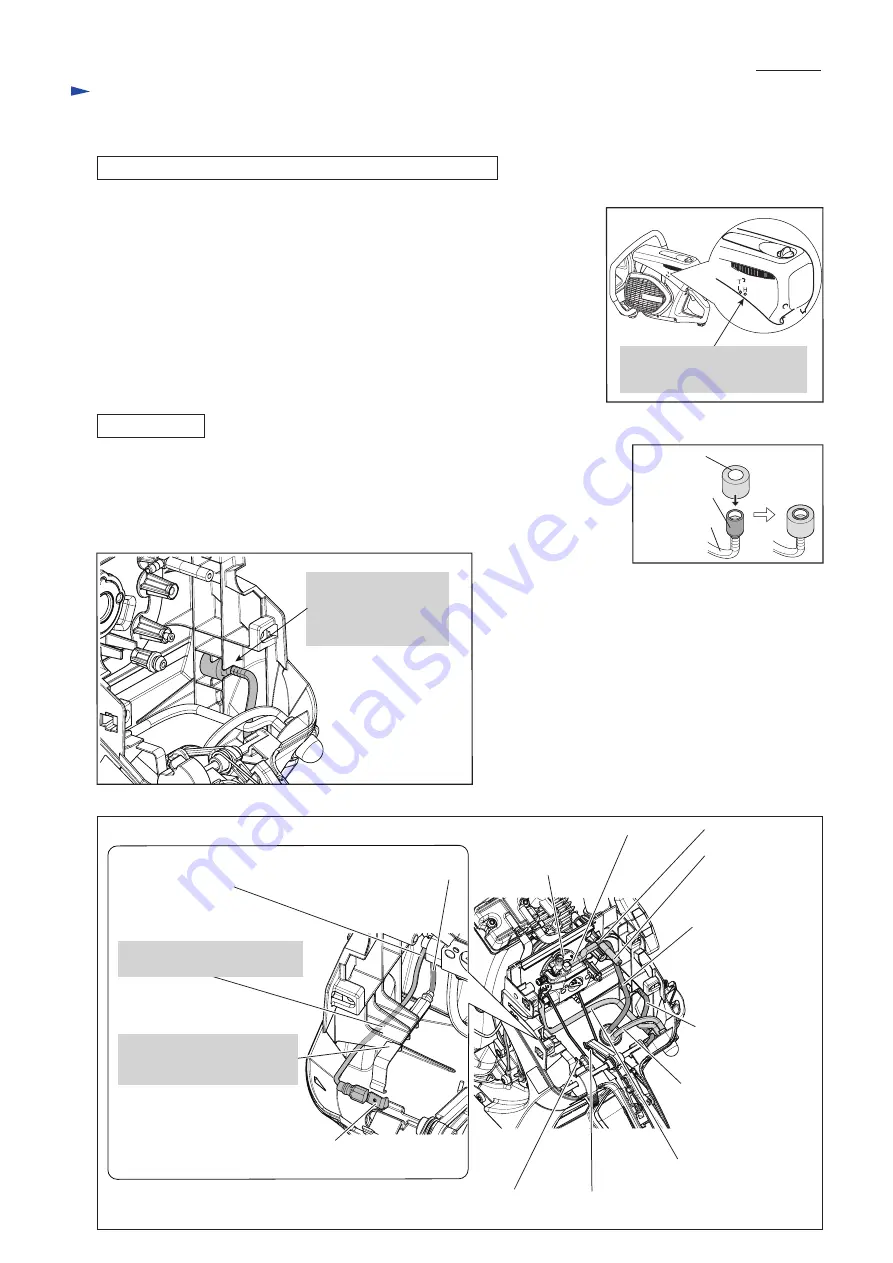

ADJUSTMENT OF CARBURETOR AFTER REPLACEMENT

ASSEMBLING

Fig. 38

Fig. 39

Fig. 40

Pull throttle lever fully after a while engine running at idle position. When there is

a problem with the engine quick acceleration, adjust H needle (

Fig. 38

) as follows:

(1) Warm up the engine by pulling the throttle lever fully for one minute.

(2) Keep engine idling and do fine adjustment of the idling speed by turning

H needle (

Fig. 38

) with a thin slotted screwdriver.

(3) Pull the throttle lever quickly. If Engine stall happens/ Engine does not reach

the maximum rpm, do step (4). If there are no problems with the engine quick

acceleration, go ahead to step (5).

(4) Unscrew H needle 1/8 turn (45°) with a thin slotted screwdriver.

After pulling the throttle lever fully with no load, retry the step (3).

(5) Push two Limiter caps (

Fig. 37

) into Carburetor with a flat top of rod.

Note

: It is not necessary to touch L needle.

Assemble by reversing the disassembly procedure. Be careful to the following points.

• Align the ends of Sponge sleeve 9 and Breather on Tube 3-190. (

Fig. 39

)

• Set Breather in place so that Tube 3-190 is fixed to the rib in Tank complete. (

Fig. 40

)

• Set Tubes, Choke linkage and Throttle linkage in place. (

Fig. 41

) Be careful to each

direction of the linkages.

Sponge

sleeve 9

Tube 3-190

Perspective view

Breather

Fig. 41

Lead unit (B) between Contact

spring and Ignition oil

Carburetor

Tube 3-120 between

Primer pump and

Grommet on

Tank complete

Tube 3-300 between

Carburetor and

Gasoline filter in

Tank complete

Tube 3-190

(Refer to

Fig. 39

.)

Throttle linkage

Choke linkage

Tube 3-45 between Hose joint

and Carburetor

Tube 3-35 from

Hose joint to

Filter bracket

Hose joint

Fix the assembled part

drawn in

Fig. 39

with

Lead wire holder in

Tank complete

Lead unit (A)

Plate on Switch lever

Tube 3-190 between

Primer pump and

Carburetor

(Refer to

Fig. 39

.)

Adjust H needle through the hole

near H mark with a thin slotted

screwdriver.

Lead unit (A) must be routed

under these ribs.

Contact spring on Lead unit

(B) end must be inserted

into these notches of ribs.